Abstract

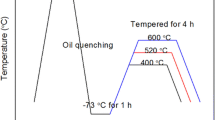

The changes of mechanical properties and carbides coarsening behavior of marine atmospheric corrosion resistant steel at different tempering processes were studied. The results of tensile and impact tests showed that the best mechanical properties obtained when the steel was quenched at 940 °C and tempered at 520 °C. The impact toughness at −20 °C increased firstly and then decreased with the tempering temperature increasing. Scanning electron microscopy (SEM) and transmission electron microscopy (TEM) observations showed that with the increase in tempering temperature, cementite particles gradually grow up and the size of cementite particles at grain boundaries was larger than that of cementite particles in grains. The coarsening of cementite may be related to the lack of Cr element during high temperature tempering, resulting in the decrease in impact toughness.

Similar content being viewed by others

References

M. Morcillo, I. Díaz, H. Cano et al., Atmospheric Corrosion of Weathering Steels. Overview for Engineers. Part I: Basic Concepts, Construct. Build. Mater., 2019, 213, p 723–737.

H. Cano, Atmospheric Corrosion of Weathering Steels. Overview for Engineers. Part II: Testing, Inspection, Maintenance, Construct. Build. Mater., 2019, 222, p 750–765.

W. Wu, Z. Zeng, X. Cheng et al., Atmospheric Corrosion Behavior and Mechanism of a Ni-Advanced Weathering Steel in Simulated Tropical Marine Environment, J. Mater. Eng. Perform., 2017, 26, p 6075–6086.

C. Pan, Y. Cui, L. Liu et al., Effect of Temperature on Corrosion Behavior of Low-Alloy Steel Exposed to a Simulated Marine Atmospheric Environment, J. Mater. Eng. Perform., 2020, 29, p 1400–1409.

X.Y. Mao, J.Y. Sun, X.M. Zhou et al., Effect of Annealing Temperature on Surface Gradient Fine Microstructure and Wear Resistance of Low-Carbon Steel, J. Mater. Eng. Perform., 2020, 29(10), p 6952–6959.

D. Ning, C.R. Dai, J.L. Wu et al., Carbide Precipitation and Coarsening Kinetics in Low Carbon and Low Alloy Steel During Quenching and Subsequently Tempering, Mater. Charact., 2021, 176, p 111111.

G. Krauss, Steels: Processing, Structure and Performance, Materials Park, OH, ASM International (2005)

Y.X. Wu, W.W. Sun, M.J. Styles et al., Cementite Coarsening during the Tempering of Fe-C-Mn Martensite, Acta Mater., 2018, 159, p 209–224.

A. Yxw, A. Wws, A. Xg et al., The Effect of Alloying Elements on Cementite Coarsening during Martensite Tempering, Acta Mater., 2020, 183, p 418–437.

Z. Chen, X.Y. Xiong, A. Cerezo et al., Three-Dimensional Atom Probe Characterization of Alloy Element Partitioning in Cementite during Tempering of Alloy Steel, Ultramicroscopy, 2007, 107(9), p 808–812.

S. Bjrklund, L.F. Donaghey and M. Hillert, The Effect of Alloying Elements on the Rate of Ostwald Ripening of Cementite in Steel, Acta Metall., 1972, 20(7), p 867–874.

S. Ghosh, Rate-Controlling Parameters in the Coarsening Kinetics of Cementite in Fe–0.6C Steels during Tempering, Scripta Mater., 2010, 63(3), p 273–276.

M. Wang, Study on Strengthening and Toughening Mechanism and Development of Production Technology of Ni Series ultra-low Temperature Steel[D]. Northeastern University, (2017)

A. Jwl, B. Yfs, C. Rdkm et al., High Strength-Superplasticity Combination of Ultrafine-Grained Ferritic Steel: The Significant Role of Nanoscale Carbides-sciencedirect, J. Mater. Sci. Technol., 2021, 83, p 131–144.

J.H. Zhou, Y.F. Shen, Y.Y. Hong et al., Strengthening a Fine-Grained Low Activation Martensitic Steel by Nanosized Carbides, Mater. Sci. Eng., 2020, 769(2), p 138471.1-138471.11.

J.W. Liang et al., In situ Neutron Diffraction in Quantifying Deformation Behaviors of Nano-Sized Carbide Strengthened UFG Ferritic Steel. Mater. Sci, Eng. A Struct. Mater. Prop. Misrostruct. Process., 2018, 726, p 298–308.

N. Q. Zhao, The Principle and Technology of Heat Treatment[M]. Mechanical Industry Press, (2012)

W.J. Hui, H. Dong, M.Q. Wang et al., Effect of Tempering Temperature on Mechanical Properties of Cr-Mo-V Series High-Strength Steel, Acta Metall. Sin., 2002, 10, p 1009–1014.

H. Xu and T.S. Li, Effect of Tempering Temperature on Microstructure and Properties of Nb Microalloyed NM500 Steel, Heat Treat. Met., 2020, 45(9), p 116–120.

Z. Xu and L.C. Zhao, Phase Change Principle of Metal Solid STATE[M], Science Press, Beijing, 2004, p 135–136

W.J. Nam and C.M. Bae, Coarsening Behavior of Cementite Particles at a Subcritical Temperature in a Medium Carbon Steel, Scripta Mater., 1999, 41(3), p 313–318.

Z.Q. Zhang, B.X. Zhou, J.A. Wang et al., Redistribution Characteristics of Mn Between α-Fe and Cementite in Low Carbon and Low Alloy Steel During Aging, J. Eng. Sci., 2020, 42(03), p 340–347.

X.Y. Mao, H. Chen, Y. Yao et al., Effect of Stress-Temperature Coupling on Gradient Alloying Induced by Punching Severe Deformation, J. Alloy. Compd., 2016, 662(6), p 436–440.

G. Miyamoto, J.C. Oh, K. Hono et al., Effect of Partitioning of Mn and Si on the Growth Kinetics of Cementite in Tempered Fe–0.6 mass% C Martensite, Acta Mater., 2007, 55(15), p 5027–5038.

L. Chang and G.D.W. Smith, The Silicon Effect in the Tempering of Martensite in Steels, Le Journal de Physique Colloques, 1984, 45(C9), p 397–401.

T. Sakuma, N. Watanabe and T. Nishizawa, The Effect of Alloying Element on the Coarsening Behavior of Cementite Particles in Ferrite, Mater. Trans., JIM, 2007, 21(3), p 159–168.

P. Tao, C. Zhang, Z.G. Yang et al., Evolution and Coarsening of Carbides in 2. 25Cr1Mo Steel Weld Metal During High Temperature Tempering, J. Iron. Steel Res. Int., 2010, 17(5), p 74–78.

Q.Y. Guo, Y.M. Li, B. Chen et al., Effect of High-Temperature Ageing on Microstructure and Creep Properties of S31042 Heat-Resistant Steel, Acta Metall. Sin., 2021, 57(01), p 82–94.

A. Fca, D. Jjwb, C. Sxz et al., Tailoring Cementite Precipitation and Mechanical Properties of Quenched and Tempered Steel by Nickel Partitioning Between Cementite and Ferrite, Mater. Sci. Eng. A, 2021, 802, p 140686.

D. K. Shi, Material Science Foundation[M]. China Machinery Industry Press (1999).

Acknowledgments

This study was funded by the Postgraduate Research and Practice Innovation Program of Jiangsu Province (SJCX20_0707), and the Science and Technology Innovation Foundation of Nanjing Institute of Technology (TB202017027).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bao, Y.K., Wu, M., Liu, K.X. et al. Effect of Tempering Temperature on Carbide Precipitation and Mechanical Properties of Marine Atmospheric Corrosion Resistant Steel. J. of Materi Eng and Perform 31, 2517–2524 (2022). https://doi.org/10.1007/s11665-021-06335-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06335-6