Abstract

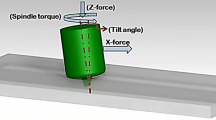

In this paper, different tool pin profiles, namely taper-threaded, triangular, and hybrid are used to join 5-mm-thick 2050-T84 Al-Cu-Li alloy by friction-stir-welding. The experiments were conducted using a one-variable-at-a-time approach by varying the geometry of tool pin profile and kept constant values of tool rotational speed, tool traverse speed, and tool tilt angle as 1400 rpm, 180 mm/min, and 2°, respectively. The objectives of this paper are to determine the effects of varying tool pin profile on force–torque behavior, microstructure, grain size distribution, tensile properties, and mode of tensile failure. It was observed that the hybrid tool produced less flash, less vertical downward force(14340.49N), low average grain size (11.27 µm) in the nugget zone, and larger weld bead area along with higher tensile strength (418.98 MPa), joint efficiency (78.44%), and micro-hardness (147HV0.1) when compared to other tools. The fractography analyses were performed using field-emission scanning electron microscope and observed ductile mode of failure for all friction stir-welded joints.

Similar content being viewed by others

References

R. Bertrand, H. Robe, D. Texier, Y. Zedan, E. Feulvarch and P. Bocher, Analysis of AA2XXX/ AA7XXX Friction Stir Welds, J. Mater. Process Technol., 2019, 271, p 312–324.

B. Ahmed and S. Wu, Aluminum-Lithium Alloys (Al-Li-Cu-X)-New Generation Material for Aerospace Applications, Appl. Mech. Mater., 2013, 440, p 104–111.

S. Kumar, D. Sethi, S. Choudhury, B.S. Roy and S.C. Saha, An Experimental Investigation to the Influence of Traverse Speed on Microstructure and Mechanical Properties of Friction Stir Welded AA2050-T84 Al-Cu-Li Alloy Plates, Mater. Today, 2020, 26(2), p 2062–2068.

J. Zhang, X.S. Feng, J.S. Gao, H. Huang, Z.Q. Ma and L.J. Guo, Effects of Welding Parameters and Post-Heat Treatment on Mechanical Properties of Friction Stir Welded AA2195-T8 Al-Li Alloy, J. Mater. Sci. Technol., 2018, 34, p 219–227.

M. Niedzinski, The Evolution of Constellium Al-Li alloy for Space Launch and Crew Module Application, Light. Met. Age, 2019, 77, p 36–42.

A.A. El-Aty, Y. Xu, X. Guo, S. Zhang, Y. Ma and D. Chen, Strengthening Mechanisms, Deformation Behavior, and Anisotropic Mechanical Properties of Al-Li Alloys: A Review, J. Adv. Res., 2018, 10, p 49–67.

O. Gharbi, N. Birbilis and K. Ogle, Li Reactivity During The Surface Pretreatment of Al-Li Alloy AA2050-T3, Electrochim. Acta., 2017, 243, p 207–219.

R.J.H.Wanhill, and G.H.Bray, Aero-Structural Design and its Application to Aluminum-Lithium Alloys. In Aluminum-Lithium Alloys: Processing, Properties, and Applications. Prasad E, Gokhale A, and Wanhill H, editors: Butterworth-Heinemann; Elsevier Inc; 2014; p 27- 58

Ph. Lequeu, K.P. Smith and A. Daniélou, Aluminum-Copper-Lithium Alloy 2050 Developed for Medium to Thick Plate, J. Mater. Eng. Perform., 2009, 19, p 841–847.

S. Kumar, U. Acharya, D. Sethi, T. Medhi, B.S. Roy and S.C. Saha, Efect of Traverse Speed on Microstructure and Mechanical Properties of Friction Stir Welded Third Generation Al–Li Alloy, J. Braz. Soc. Mech. Sci. Eng., 2020, 42(423), p 1–13.

V. Proton, J. Alexis, E. Andrieu, C. Blanc, J. Delfosse, L. Lacroix and G. Odemer, Influence of Post-Welding Heat Treatment on the Corrosion Behavior of a 2050–T3 Aluminum-Copper-Lithium Alloy Friction Stir Welding Joint, J. Electrochem. Soc., 2011, 158(5), p 39–147.

M.N. Avettand-Fènoël, F. DeGeuser and A. Deschamps, Effect of the Aging on Precipitation Spatial Distribution in Stationary Shoulder Friction Stir Welded AA2050 Alloy, Mater. Charact., 2019, 154, p 193–199.

B. Cai, Z.Q. Zheng, D.Q. He, S.C. Li and H.P. Li, Friction Stir Weld of 2060 Al-Cu-Li Alloy: Microstructure and Mechanical Properties, J. Alloys Compd., 2015, 649, p 19–27.

R.S. Mishra and H. Sidhar, Friction Stir Welding of Al–Li Alloys. Chapter-4, Friction Stir Welding of 2XXX Aluminum Alloys Including Al-Li Alloys, Butterworth-Heinemann, Oxford, 2017.

W.M. Thomas, D.G. Staines, I.M. Norris and R. de Frias, Friction Stir Welding Tools and Developments, Weld. World., 2003, 47, p 10–17.

L. Shi and C.S. Wu, Transient Model of Heat Transfer and Material Flow at Different Stages of Friction Stir Welding Process, J. Mater. Process, 2017, 25, p 323–339.

Y.N. Zhang, X. Cao, S. Larose and P. Wanjara, Review of Tools for Friction Stir Welding and Processing, Can. J. Metall. Mater. Sci., 2013, 51(3), p 250–261.

J. Stephen Leon and V. Jayakumar, Effect of Tool Shoulder and Pin Cone Angles in Friction Stir Welding using Non-Circular Tool Pin, J. Appl. Comput. Mech., 2020, 6(3), p 554–563.

S. Ugender, Influence of Tool Pin Profile and Rotational Speed on the Formation Of Friction Stir Welding Zone in AZ31 Magnesium Alloy, J Magnes Alloy, 2018, 6(2), p 205–213.

Y. Birol and S. Kasman, Effect of Welding Parameters on Microstructure and Mechanical Properties of Friction Stir Welded EN AW 5083 H111 Plates, Mater. Sci. Tech., 2013, 29(11), p 1354–1362.

K. Elangovan, V. Balasubramanian and M. Valliappan, Influences of Tool Pin Profile and Axial Force on the Formation of Friction Stir Processing Zone in AA6061 Aluminum Alloy, Int. J. Adv. Manuf. Tech., 2007, 38(3–4), p 285–295.

R. Palanivel, P. Koshy Mathews, M. Balakrishnan, I. Dinaharan and N. Murugan, Effect of Tool Pin Profile and Axial Force on Tensile Behavior in Friction Stir Welding of Dissimilar Aluminum Alloys, Adv. Mater. Res., 2012, 415, p 1140–1146.

S Budin, N C Maideen and S Sahudin (2019) Design and Development of Stirring Tool Pin Profile for Reconfigured Milling Machine to Perform Friction Stir Welding Process. In IOP Conference Series: Mater. Sci. Engg. 505: 012089.

Ch. VenkataRao, G. Madhusudhan Reddy and K. SrinivasaRao, Influence of Tool Pin Profile on Microstructure and Corrosion Behavior Of Aa2219 Al–Cu Alloy Friction Stir Weld Nuggets, Def Tech., 2015, 11(3), p 197–208.

M.M. Moradi, H.J. Aval and R. Jamaati, Effect of Tool Pin Geometry and Weld Pass Number on Microstructural, Natural Aging And Mechanical Behavior of SIC-Incorporated Dissimilar Friction-Stir-Welded Aluminium Alloys, Sådhanå., 2019, 44(9), p 1–9.

A. Singh, V. Kumar and N.K. Grover, Influence of Tool Pin Profiles on Friction Stir Welding With a Gap for AA6082-T6 Aluminum Alloy, Mater. Res. Expr., 2019, 6(8), p 8.

K. Elangovan, V. Balasubramanian and M. Valliappan, Effect of Tool Pin Profile and Tool Rotational Speed on Mechanical Properties of Friction Stir Welded AA6061 Aluminium Alloy, Mater. Manuf. Process., 2008, 23(3), p 251–260.

B. Singh, K.K. Saxena, P. Singhal and T.C. Joshi, Role of Various Tool Pin Profiles in Friction Stir Welding of AA2024 Alloys, J Mater Eng Perform, 2021 https://doi.org/10.1007/s11665-021-06017-3

H.I. Dawood, K.S. Mohammed, R. Azmi and M.B. Uday, Effect of small Tool Pin Profiles on Microstructures And Mechanical Properties Of 6061 Aluminum Alloy by Friction Stir Welding, T Non Ferr. Metals Soc., 2015, 25(9), p 2856–2865.

M. Shalin and M. Hiten, Experimental Analysis on Effect of Tool Transverse Feed, Tool Rotational Speed And Tool Pin Profile Type on Weld Tensile Strength OF Friction Stir Welded Joint of AA 6061, Mater Today: Proce, 2018, 5(1), p 487–493.

D.B. Darmadi and M. Talice, Improving the Strength of Friction Stir Welded Joint By Double Side Friction Welding and Varying Pin Geometry, Eng. Sci. Technol. Int. J., 2021, 24(3), p 637–647.

J.C. Hou, H.J. Liu and Y.Q. Zhao, Influences of Rotation Speed on Microstructures and Mechanical Properties of 6061–T6 Aluminum Alloy Joints Fabricated by Self-Reacting Friction Stir Welding Tool, Int. J. Adv. Manuf. Tech., 2014, 73(5–8), p 1073–1079.

M.M. Khalilabad, Y. Zedan, D. Texier, M. Jahazi and P. Bocher, Effect of Tool Geometry and Welding Speed on Mechanical Properties of Dissimilar AA2198–AA2024 FSWed Joint, J. Manuf. Process., 2018, 34, p 86–95.

M Guerra, CSchmidt, J. C. McClure, L. E. Murr, A. C. Nunes, and P. M. Munafo, Metal Flow during Friction Stir Welding, in Friction Stir Welding and Processing, K. V. Jata, R. S. Mishra, S. L. Semiatin, D. P. Field, Editor, 2001, TMS Indianapolis, Indiana, p. 246.

A. Tongne, C. Desrayaud, M. Jahazi and E. Feulvarch, On Material Flow in Friction Stir Welded Al alloys, J. Mater. Proc. Tech., 2017, 239, p 284–296.

Y.S. Sato, M. Urata, H. Kokawa and K. Ikeda, Hall-Petch Relationship in Friction Stir Welds of Equal Channel Angular-Pressed Aluminum Alloys, Mater. Sci. Eng. A, 2003, 354(1–2), p 298–305.

C. Du, Q. Pan, S. Chen and S. Tian, Effect of Rolling on the Microstructure And Mechanical Properties Of the T DS-FSW Plate, Mater. Sci. Eng.: A, 2019, 138692, p 1–24.

A. Jagetia, M.S.K.K.Y. Nartu, S. Dasari, A. Sharma, B. Gwalani and R. Banerjee, Ordering-Mediated Local Nano-Clustering Results in Unusually Large Hall-Petch Strengthening Coefficients in High Entropy Alloys, Mater. Res. Lett., 2019, 5, p 213–222.

Y. Li, A.J. Bushby and D.J. Dunstan, The Hall-Petch Effect as a Manifestation of the General Size Effect, Proc. R. Soc. A: Math., Phys. Eng. Sci., 2016, 472(2190), p 20150890.

L. Chun-Yi, L. Truan-Sheng, C. Li-Hui and H. Fei-Yi, Hall Petch Tensile Yield Stress and Grain Size Relation of Al5Mg05Mn Alloy in Friction-Stir-Processed and Post-Thermal-Exposed Conditions, Mater. Trans., 2014, 55(2), p 357–362.

N. Guo and M.C. Leu, Additive Manufacturing: Technology, Applications, and Research Needs, Front. Mech. Eng. Prc., 2013, 8(3), p 215–243.

P. Schempp, C.E. Cross, R. Häcker and M.R. Ethmeier, Influence of Grain Size on Mechanical Properties of Aluminum GTA Weld Metal, Weld. World., 2013, 57(3), p 293–304.

P. Goel, A.N. Siddiquee, N.Z. Khan, A. Mohd, Z.A. Hussain, M.H. Khan and A. Al-Ahmari Abidi, Investigation on the Effect of Tool Pin Profiles on Mechanical and Microstructural Properties of Friction Stir Butt And Scarf Welded Aluminium Alloy 6063, Metals, 2018, 8, p 74.

C.N. Suresha, B.M. Rajaprakash and S. Upadhya, A Study Of The Effect of Tool Pin Profiles on Tensile Strength of Welded Joints Produced Using Friction Stir Welding Process, Mater. Manuf. Proc., 2011, 26(9), p 1111–1116.

M. Yuqing, K. Liming, L. Fencheng, C. Yuhua and X. Li, Effect of Tool Pin-Tip Profiles on Material Flow and Mechanical Properties of Friction Stir Welding Thick AA7075-T6 Alloy Joints, Int J Adv Manuf Technol, 2017, 88, p 949–960.

Acknowledgment

The authors acknowledge financial assistance in terms of scholarship to carry the research work from the Ministry of Human Resource and Development (MHRD), Government. of India. The authors also acknowledge the Mechanical Engineering Department, IIT Guwahati, India (for providing the facilities of Material Testing of the welded specimen), and Tripura University (for FE-SEM analysis of tensile fracture specimen).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author has no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, S., Chaubey, S.K., Sethi, D. et al. Performance Analysis of Varying Tool Pin Profile on Friction Stir Welded 2050-T84Al-Cu-Li Alloy Plates. J. of Materi Eng and Perform 31, 2074–2085 (2022). https://doi.org/10.1007/s11665-021-06315-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06315-w