Abstract

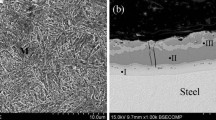

Laser welding of Al-Si coated 22MnB5 hot stamping steel/galvanized steel with different laser power, welding speed, and coating conditions were presented. The weld appearance, microstructure, and mechanical properties of the joints were investigated. With the increase of heat input (raising the laser power or lowering the welding speed), the welding seam changed from Y-shape to X-shape gradually, and the widths of the weld seam increased. The fusion zone (FZ) consisted of lath martensite (M). On the side of 22MnB5, the heat-affected zone (HAZ) was divided into coarse grain zone, refined zone, intercritical zone, and tempered zone along the direction from FZ to the base material (BM). Coarse grain zone and refined zone comprised martensite, intercritical zone comprised martensite and a little ferrite, and tempered zone comprised tempered martensite, which expressed obvious softening. On the side of galvanized steel, HAZ was mainly composed of ferrite and pearlite. Significantly, band-like δ-ferrite (a low ductility and low strength phase) was formed along the fusion boundary owing to the accumulation of the mixing of Al-Si coating and base metals. The maximum tensile shear strength of the joint was only 484 MPa in coated condition but increased to 700 MPa in de-coated condition because of the existence of δ-ferrite along the fusion boundary, which deteriorated the mechanical properties of the joints. The failure occurred at the fusion boundary (FB) in the coated conditions with a mixture of cleavage, quasi-cleavage, and dimpled fracture. However, the failure occurred at the interface in the de-coated condition with a dimpled fracture. In addition, for the coated condition, higher laser power or lower welding speeds led to wider bead width and more intense weld pool flow, which enhanced the diffusion of Al, resulted in alleviating the accumulation of Al at the fusion boundary, which increased the mechanical properties.

Similar content being viewed by others

References

H. Samuel, K. Jörgen, L. Simon and J.P. Jonsén, Ultra High Strength Steel Sandwich for Lightweight Applications, SN, Appl. Sci., 2020, 2, p 1040–1055. https://doi.org/10.1007/s42452-020-2773-5

J.H. Schmitt and T. Iung, New Developments of Advanced High-Strength Steels for Automotive Applications, C. R. Phys., 2018, 19, p 641–656. https://doi.org/10.1016/j.crhy.2018.11.004

M. Pfestorf, Manufacturing of High Strength Steel and Aluminum for a Mixed Material Body in White, J. Adv Mater. Res., 2005, 6–8, p 109–126. https://doi.org/10.4028/scientific.net.AMR.6-8.109

J. Yang, Z.H. Yu, Y.L. Li, H. Zhang and N. Zhou, Laser Welding/Brazing of 5182 Aluminium Alloy to ZEK100 Magnesium Alloy Using a Nickel Interlayer, Sci. Technol. Weld Joint., 2018, 23, p 543–550. https://doi.org/10.1080/13621718.2018.1425182

Turetta, S. Bruschi, A. Ghiotti. Investigation of 22MnB5 Formability in Hot Stamping Operations, J. Mater. Process. Techno1. 77 (2006) 396–400. https://doi.org/10.1016/j.jmatprotec.2006.04.041

D.W. Fan, H.S. Kim and B.C. De Cooman, A Review of the Physical Metallurgy Related to the Hot Press Forming of Advanced High Strength Steel, Mater. Technol., 2009, 80, p 241–248. https://doi.org/10.2374/SRI08SP131

H. Karbasian and A.E. Tekkaya, A Review on Hot Stamping, J. Mater. Process. Technol., 2010, 210, p 2103–2118. https://doi.org/10.1016/j.jmatprotec.2010.07.019

K. Mori and D. Ito, Prevention of Oxidation in Hot Stamping of Quenchable Steel Sheet by Oxidation Preventive Oil, CIRP. Ann. Manuf. Technol., 2009, 58, p 267–270. https://doi.org/10.1016/j.cirp.2009.03.055

O.L. Ighodaro, E. Biro and Y.N. Zhou, Comparative Effects of Al-Si and Galvannealed Coatings on the Properties of Resistance Spot Welded Hot Stamping Steel Joints, J. Mater. Process. Technol., 2016, 236, p 64–72. https://doi.org/10.1016/j.jmatprotec.2016.03.021

Otani, T., Ken. Characteristics of Resistance Spot Welds of Ultra-Fine Grained High Strength Steel Sheets. Yosetsu GakkAiRonbunshu/Quarterl, J. Japan Weld. Soc. 21 (2003) 243-248.

F. Vollertsen, P. Woizeschke, V. Schultz and C. Mittelstädt, Developments for Laser Joining With High Quality Seam Surfaces, Lightweight, Des. World, 2017, 10, p 6–13. https://doi.org/10.1007/s41777-017-0041-1

M.S. Khan, M.H. Razmpoosh, E. Biro and Y. Zhou, A review on the Laser Welding of Coated 22MnB5 Press-Hardened Steel and Its Impact on the Production of Tailor-Welded Blanks, Sci. Technol. Weld. Join., 2020, 25, p 447–467. https://doi.org/10.1080/13621718.2020.1742472

J. Wang, L. Yang, M. Sun, T. Liu and H. Li, A Study of the Softening Mechanisms of Laser-Welded DP1000 Steel Butt Joints, Mater. Des., 2016, 97, p 118–125. https://doi.org/10.1016/j.matdes.2016.02.071

W. Guo, Z.D. Wan, Q. Jia, L.X. Ma, H.Q. Zhang, C.W. Tan and P. Peng, Laser Weldability of TWIP980 with DP980/B1500HS/QP980 Steels: Microstructure and Mechanical Properties, Opt. Laser Technol., 2020, 124, p 1–10. https://doi.org/10.1016/j.optlastec.2019.105961

M.H. Razmpoosh, A. Macwan, E. Biro and Y. Zhou, Microstructure and Dynamic Tensile Characteristics of Dissimilar Fiber Laser Welded Advanced High Strength Steels, Mater. Sci. Eng. A., 2020, 773, p 1–10. https://doi.org/10.1016/j.msea.2019.138729

M. Kang and C. Kim, Analysis of Laser and Resistance Spot Weldments on Press-Hardened Steel, Mater. Sci. Forum., 2011, 695, p 202–205.

J. Jia, S.L. Yang, W.Y. Ni and J.Y. Bai, Microstructure and Mechanical Properties of Fiber Laser Welded Joints of Ultrahigh-Strength Steel 22MnB5 and Dual-phase Steels, J. Mater. Res., 2014, 29, p 2565–2575. https://doi.org/10.1557/jmr.2014.273

B. Gerhards, U. Reisgen and S. Olschok, Laser Welding of Ultrahigh Strength Steels at Subzero Temperatures, Phys. Procedia., 2016, 83, p 352–361. https://doi.org/10.1016/j.phpro.2016.08.037

C. Kim, M.J. Kang and Y.D. Park, Laser Welding of Al-Si Coated Hot Stamping Steel, Pro. Eng., 2011, 10, p 2226–2231. https://doi.org/10.1016/j.proeng.2011.04.368

X. He, Y.Q. Qin and W.X. Jiang, Effect of Welding Parameters on Microstructure and Mechanical Properties of Laser Welded Al-Si Coated 22MnB5 Hot Stamping Steel, J. Mater. Process. Technol., 2019, 270, p 285–290. https://doi.org/10.1016/j.jmatprotec.2019.03.006

M. Kang, C. Kim and J. Lee, Weld Strength of Laser-Welded Hot-Press-Forming Steel, J. Laser Appl., 2012, 24, p 208–219. https://doi.org/10.2351/1.3699080

M.S. Khan, M.H. Razmpoosh, A. Macwan, E. Biro and Y. Zhou, Optimizing Weld Morphology and Mechanical Properties of Laser Welded Al-Si Coated 22MnB5 by Surface Application of Colloidal Graphite, J. Mater. Process. Tech., 2021, 293, 117093. https://doi.org/10.1016/j.jmatprotec.2021.117093

D.C. Saha, E. Biro, A.P. Gerlich and Y.N. Zhou, Fiber Laser Welding of Al-Si Coated Press-Hardened Steel, Weld. J., 2016, 95, p 147s–156s.

Q. Sun, H.S. Di, X.N. Wang, X.M. Chen, X.N. Qi and J.P. Li, A Study on Microstructure and Properties of PHS Fiber Laser Welded Joints Obtained in Air Atmospheres, Materials., 2018, 11, p 1135. https://doi.org/10.3390/ma11071135

T.J. Yoon, M.H. Oh, H.J. Shin and C.Y. Kang, Comparison of Microstructure and Phase Transformation of Laser Welded Joints in Al-10wt%Si-Coated Boron Steel Before and After Hot Stamping, Mater. Charact., 2017, 128, p 195–202. https://doi.org/10.1016/j.matchar.2017.02.007

W.H. Lin, F. Li, D.S. Wu, X.G. Chen, X.M. Hua and H. Pan, Effect of Al-Si Coating on Weld Microstructure and Properties of 22MnB5 Steel Joints for Hot Stamping, J. Mater. Eng. Perform., 2017, 27, p 1825–1836. https://doi.org/10.1007/s11665-018-3259-0

W.H. Lin, F. Li, X. Hua and D. Wu, Effect of Filler Wire on Laser Welded Blanks of Al-Si-Coated 22MnB5 Steel, J. Mater. Process. Technol., 2018, 259, p 195–205. https://doi.org/10.1016/j.jmatprotec.2018.04.041

D.C. Saha, E. Biro, A.P. Gerlich and Y.N. Zhou, Fusion Zone Microstructure Evolution of Fiber Laser Welded Press Hardened Steels, Scripta Mater., 2016, 121, p 18–22. https://doi.org/10.1016/j.scriptamat.2016.04.032

S.L. Min, J.H. Moon and C.G. Kang, Investigation of Formability and Surface Micro-Crack in Hot Deep Drawing by Using Laser-Welded Blank of Al-Si and Zn-Coated Boron Steel, J. Eng. Manuf., 2014, 228, p 540–552. https://doi.org/10.1177/0954405413501810

Acknowledgments

The authors sincerely acknowledge the support of Shanghai Collaborative Innovation Center of Laser Advanced Manufacturing Technology (Shanghai University of Engineering Science). This research was financially supported by Shanghai Science and Technology Committee Innovation Grant (17JC1400600, 17JC1400601).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, D., Qin, Y., Zhao, F. et al. Microstructure and Mechanical Properties of Laser Welded Al-Si Coated 22MnB5 Hot Stamping Steel and Galvanized Steel. J. of Materi Eng and Perform 31, 1346–1357 (2022). https://doi.org/10.1007/s11665-021-06291-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06291-1