Abstract

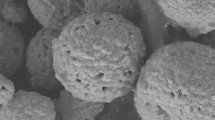

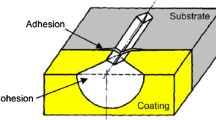

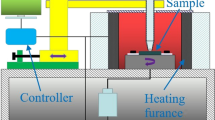

NiCr coating was prepared on the surface of AISI 1045 steel substrate by cold spraying. The microstructure, phase composition and mechanical properties of the NiCr coating were studied, the wear resistance and corrosion resistance of the NiCr coating were compared with the steel substrate. The results showed that the particles had serious plastic deformation in the process of cold spraying, no oxidation and phase transformation occurred in NiCr coating, and the grain size was bimodal distribution. The average surface hardness of the NiCr coating was as high as 574 HV0.2, the porosity was 0.83%, the fracture toughness was 2.18 MPa·m1/2, and the coating was well combined with the substrate. The friction coefficient of the NiCr coating was lower than that of the substrate, the wear rate was only 1/3 of that of the substrate, and its wear mechanism was mainly abrasive wear. In 3.5% NaCl solution, the corrosion potential of the coating (−0.3970 V) shifted positively with respect to the substrate (−0.7322 V), indicating that the coating had good corrosion resistance. Therefore, NiCr coating prepared by cold spraying can provide effective wear and corrosion protection for steel substrate.

Similar content being viewed by others

References

M. Daroonparvar, M.U. Farooq Khan, Y. Saadeh, C.M. Kay, A.K. Kasar, P. Kumar, M. Misra, P. Menezes, P.R. Kalvala, R.K. Gupta, H.R. Bakhsheshi-Rad and L. Esteves, Modification of Surface Hardness, Wear Resistance and Corrosion Resistance of Cold Spray Al Coated AZ31B Mg Alloy Using Cold Spray Double Layered Ta/Ti Coating in 3.5wt.%NaCl Solution, Corros. Sci., 2020, 176, p 109029–109036.

M.L. Zhong, W.J. Liu and H.J. Zhang, Corrosion and Wear Resistance Characteristics of NiCr Coating by laser Alloying with Powder Feeding on Grey Iron Liner, Wear, 2006, 260(11), p 1349–1355.

Z. Aramian, K.G.P. Sadeghian and F. Berto, In Situ Fabrication of TiC-NiCr Cermets by Selective Laser Melting, Int. J. Refract. Met. Hard Mater., 2019, 87(c), p 105171.

K. Santosh, K. Manoj and H. Amit, Comparative Study of High Temperature Oxidation Behavior and Mechanical Properties of Wire Arc Sprayed Ni Cr and Ni Al Coatings, Eng. Failure Anal., 2019, 106(C), p 104173–104173.

G. Guo, Preparation and Characterization of Plasma Sprayed NiCr, Crsub3/subCsub2/sub-NiCr Coatings for Boiler Pipeline Protection, Chem. Eng., 2018, 62(012), p 32–36. (in Chinese)

S. Swaminathana, S.M. Hongb, M. Kumar, W.S. Jungb, D.I. Kimb, H. Singhd and In-Suk. Choi, Microstructural Evolution and High Temperature Oxidation Characteristics of Cold Sprayed Ni-20Cr Nanostructured Alloy Coating, Surf. Coat. Technol., 2019, 362, p 333–344.

W.Y. Li, K. Yang, S. Yin, X.W. Yang, Y.X. Xu and R. Lupoi, Solid-State Additive Manufacturing and Repairing by Cold Spraying: A Review, J. Mater. Sci. Technol., 2018, 34(3), p 440–457.

N. Kang, C. Verdy, P. Coddet, Y. Xie, Y. Fu, H. Liao and C. Coddet, Effects of Laser Remelting Process on the Microstructure, Roughness and Microhardness of In-situ Cold Sprayed Hypoeutectic Al-Si Coating, Surf. Coat. Technol., 2017, 318, p 355–359.

Q. Liu, X.Y. Wang, Y.B. Huang, L. Xie, Q. Xu and L.H. Li, Effect of Mo Content on Microstructure and Corrosion Resistance of CoCrFeNiMo High Entropy Alloy, J. Mater. Sci. Res., 2020, 34(11), p 70–76. (in Chinese)

E. Lapushkina, S. Yuan, N. Mary, J. Adrien and B. Normand, Contribution in Optimization of Zn Cold-Sprayed Coating Dedicated to Corrosion Applications, Surf. Coat. Technol., 2020, 400, p 126193–126201.

A.A. Tiamiyu and C.A. Schuh, Particle Flattening During Cold Spray: Mechanistic Regimes Revealed by Single Particle Impact Tests, Surf. Coat. Technol., 2020, 403, p 126386–126395.

S. Kumar, S.K. Reddy and S.V. Joshi, Microstructure and Performance of Cold Sprayed Al-SiC Composite Coatings with High Fraction of Particulates, Surf. Coat. Technol., 2017, 318, p 362–369.

Y.K. Wei, X.T. Luo, X. Chu, G.S. Huang and C.J. Li, Solid-State Additive Manufacturing High Performance Aluminum Alloy 6061 Enabled by an In-situ Micro-Forging Assisted Cold Spray, Mater. Sci. Eng. A, 2020, 776, p 1–9.

C.J. Huang, W.Y. Li, M. Yu and H.L. Liao, Study on Preparation of Particle Reinforced Titanium Matrix Composite Coating by Cold Spraying, Mate. Eng., 2013, 04, p 27–36.

E. Sansoucy, P. Marcoux, L. Ajdelsztajn and B. Jodoin, Properties of SiC-Reinforced Aluminum Alloy Coatings Produced by the Cold Gas Dynamic Spraying Process, Surf. Coat. Technol., 2008, 202(16), p 3988–3996.

D.J. Lim, N.A. Marks and M.R. Rowles, Universal Scherrer Equation for Graphene Fragments, Carbon, 2020, 162, p 475–480.

J.H. Yao, L.J. Yang, B. Li and Z.H. Li, Beneficial Effects of Laser Irradiation on the Deposition Process of Diamond/Ni60 Composite Coating with Cold Spray, Appl. Surf. Sci., 2015, 330, p 300–308.

X.T. Luo, M.L. Yao, N. Ma, M. Takahashi and C.J. Li, Deposition Behavior, Microstructure and Mechanical Properties of an In-situ Micro-Forging Assisted Cold Spray Enabled Additively Manufactured Inconel 718 Alloy, Mater. Des., 2018, 155, p 384–395.

Y. Zou, W. Qin, E. Irissou, J.G. Legoux, S. Yue and J.A. Szpunar, Dynamic Recrystallization in the Particle/Particle Interfacial Region of Cold-Sprayed Nickel Coating: Electron Backscatter Diffraction Characterization, Scr. Mater., 2009, 61(9), p 899–902.

M.P. Planche, W.Y. Li and C.J. Huang, Microstructural Evolution and Mechanical Property Enhancement of a Cold Sprayed Cu-Zn Alloy Coating by Post-Spray Friction Stir Processing, DVS Ber., 2017, 44(7), p 104–112.

C.Y. Chen, Y.C. Xie, L.T. Liu, R.X. Zhao and Z.M. Ren, Cold Spray Additive Manufacturing of Invar 36 Alloy: Microstructure, Thermal Expansion and Mechanical Properties, J. Mater. Sci. Technol., 2021, 72, p 39–51.

J.Y. Lek, A. Bhowmik, W.Y. Tan, W. Sun and C.B. Boothroyd, Understanding the Microstructural Evolution of Cold Sprayed Ti-6Al-4V Coatings on Ti-6Al-4V Substrates, Appl. Surf. Sci, 2018, 459, p 126–134.

X.J. Jiang, N. Overman, C. Smith and K. Ross, Microstructure, Hardness and Cavitation Erosion Resistance of Different Cold Spray Coatings on Stainless Steel 316 for Hydropower Applications, Mater. Today Commun., 2020, 25, p 101305–101314.

J.M. Yuan, T.S. Dong, B.G. Fu, G.L. Li and R. Wang, Effect of Tungsten Inert Gas Arc Remelting on Microstructure and Wear Properties of Plasma-Sprayed NiCr-Cr3C2 Coating, J. Mater. Eng. Perform., 2019, 28(3), p 6320–6329.

G.L. Li, J.M. Yuan, T.S. Dong, X.W. Zhao, B.G. Fu and J.D. Shi, Wear Resistance under Different Temperatures of NiCr-Cr 3 C 2 Coating Remelted by Tungsten Inert Gas Arc, J. Mater. Eng. Perform., 2020, 29, p 1–12.

C.B. Wang, Tribological Materials and Surface Engineering, National Defense Industry Press, Beijing, 2012, p 66–94

Y. Zhang, Q. Wang, G. Chen and C.S. Ramachandran, Mechanical, Tribological and Corrosion Physiognomies of CNT-Al Metal Matrix Composite (MMC) Coatings Deposited by Cold Gas Dynamic Spray (CGDS) Process, Surf. Coat. Technol., 2020, 403, p 126380–126387.

S.A. Alidokht, P. Manimunda, P. Vo, S. Yue and R.R. Chromik, Cold Spray Deposition of a Ni-WC Composite Coating and its Dry Sliding Wear Behavior, Surf. Coat. Technol, 2016, 308, p 424–434.

S.A. Alidokht, S. Yue and R.R. Chromik, Effect of WC Morphology on Dry Sliding Wear Behavior of Cold-Sprayed Ni-WC Composite Coatings, Surf. Coat. Technol., 2019, 357, p 849–863.

C.Y. Chen, Y.C. Xie, X.C. Yan, M. Ahmed, R. Lupoi, J. Wang, Z.M. Ren, H.L. Liao and S. Yin, Tribological Properties of Al/Diamond Composites Produced by Cold Spray Additive Manufacturing, Addit. Manuf., 2020, 36, p 45–54.

X.L. Xie, B. Hosni, C.Y. Chen, H.J. Wu and H.L. Liao, Corrosion Behavior of Cold Sprayed 7075Al Composite Coating Reinforced with TiB2 Nanoparticles, Surf. Coat. Technol., 2020, 404(1), p p126460-126467.

S. Tripathy, A. Behera, S. Pati and S. Roy, Corrosion Resistant Nickel Coating on Mild Steel by Cold Gas Dynamic Spraying, Mater. Today: Proc., 2020. https://doi.org/10.1016/j.matpr.2020.09.668.

Z.C. Zhang, F.C. Liu, E.H. Han and L. Xu, Mechanical and Corrosion Properties in 3.5% NaCl Solution of Cold Sprayed Al-Based Coatings, Surf. Coat. Technol., 2020, 385, p 125372–125381.

S. Peng, J. Xu, Z.Y. Li, S.Y. Jiang, Z.H. Xie and P. Munroe, Electrochemical Noise Analysis of Cavitation Erosion Corrosion Resistance of NbC Nanocrystalline Coating in a 3.5 wt% NaCl Solution, Surf. Coat. Technol., 2021, 415, p 127–133.

P. Bijalwan, C. Singh, A. Kumar, K. Sarkar, N. Rani, T. Laha, A. Banerjee and K. Mondal, Corrosion Behaviour of Plasma Sprayed Fe Based Metallic Glass (Fe73Cr2Si11B11C3 (at%) Coatings in 3.5% NaCl Solution, J. Non-Cryst. Solids, 2021, 567, p p120913-120925.

Acknowledgment

The work was financially supported by the National Natural Science Foundation of China No. 51675158.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, Yj., Dong, Ts., Fu, Bg. et al. Study of the Microstructure and Properties of Cold Sprayed NiCr Coating. J. of Materi Eng and Perform 30, 9067–9077 (2021). https://doi.org/10.1007/s11665-021-06075-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06075-7