Abstract

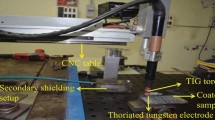

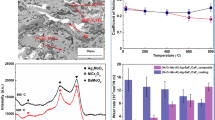

The present study aims to assess the effect of Ag/BaF2 solid lubricant encapsulation in the nickel-based composite coatings for high-temperature tribological applications. The composite coatings (NiCrSiB/WC and NiCrSiB/WC/Ag/BaF2) have successfully been fabricated on the titanium 31 substrate by tungsten inert gas (TIG) cladding technique. The influence of the TIG processing current on the microstructure, microhardness, and fracture toughness was investigated. Mechanical characteristics of the coatings were further correlated with the microstructural morphologies. The coating fabricated at 70 A exhibited significantly higher hardness than other coatings. The tribological performances of the NiCrSiB/WC/Ag/BaF2 composite coatings were superior to those of the NiCrSiB/WC coatings at both low (200 °C) and high (600 °C) temperatures. The synergistic lubrication effect of the Ag/BaF2 solid lubricant combination provided lubrication at a wide range of temperatures. The addition of these solid lubricants in the nickel-based coating helped achieve the low coefficient of friction of 0.2 and lower wear rates. Particularly, oxide phases (such as NiO, TiO, Ni3Ti3O, and W3O) formed on the worn surface at 600 °C, and the lubricant phases (Ag, Ag2F, and Ba (TiO3)) provided excellent resistance to wear.

Similar content being viewed by others

References

P.F. Mendez, N. Barnes, K. Bell, S.D. Borle, S.S. Gajapathi, S.D. Guest, H. Izadi, A.K. Gol and G. Wood, Welding Processes for Wear Resistant Overlays, J. Manuf. Process., 2014, 16(1), p 4–25.

D.E. Wolfe, J. Singh, J. Senderson and J. Zabinski, Laser-Clad Composite Coatings, Adv. Mater. Process., 2000, 158, p 41–44.

S. Buytoz, M. Ulutan and M.M. Yildirim, Dry Sliding Wear Behavior of TIG Welding Clad WC Composite Coatings, Appl. Surf. Sci., 2005, 252(5), p 1313–1323.

T. Liyanage, G. Fisher and A.P. Gerlich, Influence of Alloy Chemistry on Microstructure and Properties in NiCrBSi Overlay Coatings Deposited by Plasma Transferred Arc Welding (PTAW), Surf. Coatings Technol., 2010, 205(3), p 759–765. https://doi.org/10.1016/j.surfcoat.2010.07.095

M.R. Ramesh, S. Prakash, S.K. Nath, P.K. Sapra and B. Venkataraman, Solid Particle Erosion of HVOF Sprayed WC-Co/NiCrFeSiB Coatings, Wear, 2010, 269(3–4), p 197–205. https://doi.org/10.1016/j.wear.2010.03.019

Z. Weng, A. Wang, X. Wu, Y. Wang and Z. Yang, Wear Resistance of Diode Laser-Clad Ni/WC Composite Coatings at Different Temperatures, Surf. Coat. Technol., 2016, 304, p 283–292. https://doi.org/10.1016/j.surfcoat.2016.06.081

S. Zhou, Y. Huang, X. Zeng and Q. Hu, Microstructure Characteristics of Ni-Based WC Composite Coatings by Laser Induction Hybrid Rapid Cladding, Mater. Sci. Eng. A, 2008, 480(1–2), p 564–572.

M. Sabzi, S.M. Dezfuli and S.M. Far, Deposition of Ni-Tungsten Carbide Nanocomposite Coating by TIG welding: Characterization and Control of Microstructure and Wear/Corrosion Responses, Ceram. Int., 2018, 44(18), p 22816–22829. https://doi.org/10.1016/j.ceramint.2018.09.073

X. Luo, J. Li and G.J. Li, Effect of NiCrBSi Content on Microstructural Evolution, Cracking Susceptibility and Wear Behaviors of Laser Cladding WC/Ni-NiCrBSi Composite Coatings, J. Alloys Compd., 2015, 626, p 102–111.

H. yu Wang, D. wen Zuo, Y. li Sun, F. Xu, and D. Zhang, , Microstructure of Nanometer Al2O3 Dispersion Strengthened Ni-Based High-Temperature Protective Coatings by Laser Cladding, Trans. Nonferrous Met. Soc. China, 2009, 19(3), p 586–591.

V. Fallah, M. Alimardani, S.F. Corbin and A. Khajepour, Impact of Localized Surface Preheating on the Microstructure and Crack Formation in Laser Direct Deposition of Stellite 1 on AISI 4340 Steel, Appl. Surf. Sci., 2010, 257(5), p 1716–1723. https://doi.org/10.1016/j.apsusc.2010.09.003

X.J. Tian, S.Q. Zhang, A. Li and H.M. Wang, Effect of Annealing Temperature on the Notch Impact Toughness of a Laser Melting Deposited Titanium Alloy Ti-4Al-1.5Mn, Mater. Sci. Eng. A, 2010, 527(7–8), p 1821–1827. https://doi.org/10.1016/j.msea.2009.11.014

F. Gustavsson and S. Jacobson, Diverse Mechanisms of Friction Induced Self-Organisation into a Low-Friction Material - An Overview of WS2 Tribofilm Formation, Tribol. Int., 2016, 101, p 340–347. https://doi.org/10.1016/j.triboint.2016.04.029

X. Quan, M. Hu, X. Gao, Y. Fu, L. Weng, D. Wang, D. Jiang and J. Sun, Friction and Wear Performance of Dual Lubrication Systems Combining WS2-MoS2 Composite Film and Low Volatility Oils Under Vacuum Condition, Tribol. Int., 2016, 99, p 57–66. https://doi.org/10.1016/j.triboint.2016.03.009

T.F. Babuska, A. Pitenis, M. Jones, B.L. Nation, W.G. Sawyer and N. Argibay, Temperature Dependent Friction Behavior of PTFE and MoS2, Tribol. Lett., 2016, 63, p 1–12.

K. Jin, Z. Qiao, S. Zhu, J. Cheng, B. Yin and J. Yang, Friction and Wear Properties and Mechanism of Bronze-Cr-Ag Composites under Dry-Sliding Conditions, Tribol. Int., 2016, 96, p 132–140. https://doi.org/10.1016/j.triboint.2015.12.031

J. Li, Y. He, D. Xiong, Y. Qin, J. Chen and H. Zhu, Tribological Properties of Silver Coatings with Laser Surface Textured Nickel as Interlayer, Tribol. Int., 2016, 100, p 178–185. https://doi.org/10.1016/j.triboint.2016.01.009

S.M. Aouadi, Y. Paudel, B. Luster, S. Stadler, P. Kohli, C. Muratore, C. Hager and A.A. Voevodin, Adaptive Mo 2N/MoS 2/Ag Tribological Nanocomposite Coatings for Aerospace Applications, Tribol. Lett., 2008, 29(2), p 95–103.

M.E. Cura, X.W. Liu, U. Kanerva, S. Varjus, A. Kivioja, O. Söderberg and S.P. Hannula, Friction Behavior of Alumina/Molybdenum Composites and Formation of MoO3-x Phase at 400 °c, Tribol. Int., 2015, 87, p 23–31. https://doi.org/10.1016/j.triboint.2015.02.010

H. Torres, T. Vuchkov, S. Slawik, C. Gachot, B. Prakash and M. Rodríguez, Ripoll, Self-Lubricating Laser Claddings for Reducing Friction and Wear from Room Temperature to 600 °C, Wear, 2018, 408–409, p 22–33. https://doi.org/10.1016/j.wear.2018.05.001

C.K. Sahoo and M. Masanta, Microstructure and Tribological Behaviour of TiC-Ni-CaF2 Composite Coating Produced by TIG Cladding Process, J. Mater. Process. Technol., 2017, 243, p 229–245. https://doi.org/10.1016/j.jmatprotec.2016.12.028

C. Huang, L. Du and W. Zhang, Effects of Solid Lubricant Content on the Microstructure and Properties of NiCr/Cr3C2-BaF2·CaF2 Composite Coatings, J. Alloys Compd., 2009, 479(1–2), p 777–784.

M. Doddamani, M. Mathapati and M.R. Ramesh, Microstructure and Tribological Behavior of Plasma Sprayed NiCrAlY/WC-Co/Cenosphere/Solid Lubricants Composite Coatings, Surf. Coatings Technol., 2018, 354, p 92–100. https://doi.org/10.1016/j.surfcoat.2018.09.018

A. Lipp, K.A. Schwetz and K. Hunold, Hexagonal Boron Nitride: Fabrication, Properties and Applications, J. Eur. Ceram. Soc., 1989, 5(1), p 3–9. https://doi.org/10.1016/0955-2219(89)90003-4

Y. Kimura, T. Wakabayashi, K. Okada, T. Wada and H. Nishikawa, Boron Nitride as a Lubricant Additive, Wear, 1999, 232(2), p 199–206. https://doi.org/10.1016/S0043-1648(99)00146-5

X.L. Lu, X.B. Liu, P.C. Yu, S.J. Qiao, Y.J. Zhai, M. Di Wang, Y. Chen and D. Xu, Synthesis and Characterization of Ni60-HBN High Temperature Self-Lubricating Anti-Wear Composite Coatings on Ti6Al4V Alloy by Laser Cladding, Opt. Laser Technol., 2016, 78, p 87–94. https://doi.org/10.1016/j.optlastec.2015.10.005

T. Otani, Titanium Welding Technology, Nippon Steel Tech. Rep., 2007, 95, p 88–92.

A.E. Yaedu and A.S.C.M. D’Oliveira, Cobalt Based Alloy PTA Hardfacing on Different Substrate Steels, Mater. Sci. Technol., 2005, 21(4), p 459–466. https://doi.org/10.1179/174328413X13789824293380

A.G. Evans and T.R. Wilshaw, Quasi-Static Solid Particle Damage in Brittle Solids—I, Obs. Anal. Implic. Acta Metall., 1976, 24(10), p 939–956. https://doi.org/10.1016/0001-6160(76)90042-0

P.R. Reinaldo and A.S.C.M. D’Oliveira, NiCrSiB Coatings Deposited by Plasma Transferred Arc on Different Steel Substrates, J. Mater. Eng. Perform., 2013, 22(2), p 590–597.

P. Wu, H.M. Du, X.L. Chen, Z.Q. Li, H.L. Bai and E.Y. Jiang, Influence of WC Particle Behavior on the Wear Resistance Properties of Ni-WC Composite Coatings, Wear, 2004, 257(1–2), p 142–147.

S.J. Bull, A.M. Jones and A.R. McCabe, Residual Stress in Ion-Assisted Coatings, Surf. Coat. Technol., 1992, 54–55, p 173–179. https://doi.org/10.1016/S0257-8972(09)90046-9

H. Yan, P. Zhang, Z. Yu, Q. Lu, S. Yang and C. Li, Microstructure and Tribological Properties of Laser-Clad Ni-Cr/TiB 2 Composite Coatings on Copper with the Addition of CaF 2, Surf. Coat. Technol., 2012, 206(19–20), p 4046–4053. https://doi.org/10.1016/j.surfcoat.2012.03.086

S. Lu, J. Zhou, L. Wang and J. Liang, Effect of V and Cr Transition Layers on Microstructure and Mechanical Properties of Ni-Based Coating on Titanium Alloy Fabricated by Laser Cladding, Surf. Coat. Technol., 2021, 405, p 126734. https://doi.org/10.1016/j.surfcoat.2020.126734

X. Jiao, J. Wang, C. Wang, Z. Gong, X. Pang and S.M. Xiong, Effect of Laser Scanning Speed on Microstructure and Wear Properties of T15M Cladding Coating Fabricated by Laser Cladding Technology, Opt. Lasers Eng., 2018, 110, p 163–171. https://doi.org/10.1016/j.optlaseng.2018.05.024

Y. Chen, F. Lu, K. Zhang, P. Nie, S.R. Elmi Hosseini, K. Feng, Z. Li and P.K. Chu, Investigation of Dendritic Growth and Liquation Cracking in Laser Melting Deposited Inconel 718 at Different Laser Input Angles, Mater. Des., 2016, 105, p 133–141. https://doi.org/10.1016/j.matdes.2016.05.034

A. Öztürk, K.V. Ezirmik, K. Kazmanli, M. Ürgen, O.L. Eryilmaz and A. Erdemir, Comparative Tribological Behaviors of TiN{single Bond}, CrN{single Bond} and MoN{single Bond}Cu Nanocomposite Coatings, Tribol. Int., 2008, 41(1), p 49–59.

P.J. Blau, Elevated-Temperature Tribology of Metallic Materials, Tribol. Int., 2010, 43(7), p 1203–1208. https://doi.org/10.1016/j.triboint.2010.01.003

E. Badisch, G.A. Fontalvo, M. Stoiber and C. Miterrer, Tribological Behavior of PACVD TiN Coatings in the Temperature Range up to 500 °C, Surf. Coatings Technol., 2003, 163–164, p 585–590.

Q. Liu, T. He, W.Y. Guo, Y. Bai, Y.S. Ma, Z.D. Chang, H.B. Liu, Y.X. Zhou, F. Ding, Y.W. Sun, Z.F. Han and J.J. Tang, Tribological Behavior of SAPS Sprayed Al 2 O 3 -TiO 2 and NiCr-Cr 3 C 2 Coatings under Severe Load Conditions, Surf. Coatings Technol., 2018, 2019(370), p 362–373.

W. Wang, Application of a High Temperature Self-Lubricating Composite Coating on Steam Turbine Components, Surf. Coat. Technol., 2004, 177–178, p 12–17.

S. Zhu, Q. Bi, J. Yang and W. Liu, Ni 3Al Matrix Composite with Lubricious Tungstate at High Temperatures, Tribol. Lett., 2012, 45(2), p 251–255.

I. Tudela, A.J. Cobley and Y. Zhang, Tribological Performance of Novel Nickel-Based Composite Coatings with Lubricant Particles, Friction, 2019, 7(2), p 169–180.

X.B. Liu, X.J. Meng, H.Q. Liu, G.L. Shi, S.H. Wu, C.F. Sun, M. Di Wang and L.H. Qi, Development and Characterization of Laser Clad High Temperature Self-Lubricating Wear Resistant Composite Coatings on Ti-6Al-4V Alloy, Mater. Des., 2014, 55, p 404–409. https://doi.org/10.1016/j.matdes.2013.09.038

M. Niu, Q. Bi, J. Yang and W. Liu, Tribological Performance of a Ni 3Al Matrix Self-Lubricating Composite Coating Tested from 25 to 1000°C, Surf. Coat. Technol., 2012, 206(19–20), p 3938–3943. https://doi.org/10.1016/j.surfcoat.2012.03.064

M. Aristizabal, L.C. Ardila, F. Veiga, M. Arizmendi, J. Fernandez and J.M. Sánchez, Comparison of the Friction and Wear Behaviour of WC-Ni-Co-Cr and WC-Co Hardmetals in Contact with Steel at High Temperatures, Wear, 2012, 280–281, p 15–21. https://doi.org/10.1016/j.wear.2012.01.015

S. Zhu, Q. Bi, J. Yang, W. Liu and Q. Xue, Ni3Al Matrix High Temperature Self-Lubricating Composites, Tribol. Int., 2011, 44(4), p 445–453. https://doi.org/10.1016/j.triboint.2010.11.016

J. Zhen, F. Li, S. Zhu, J. Ma, Z. Qiao, W. Liu and J. Yang, Friction and Wear Behavior of Nickel-Alloy-Based High Temperature Self-Lubricating Composites Against Si3N4 and Inconel 718, Tribol. Int., 2014, 75, p 1–9. https://doi.org/10.1016/j.triboint.2014.03.005

I.A. Inman, S.R. Rose and P.K. Datta, Studies of High Temperature Sliding Wear of Metallic Dissimilar Interfaces II: Incoloy MA956 Versus Stellite 6, Tribol. Int., 2006, 39(11), p 1361–1375.

Y. Mao, J. Yan, L. Wang, W. Dong, Y. Jia, X. Hu and X. Wang, Formation and Properties of Bioactive Barium Titanate Coatings Produced by Plasma Electrolytic Oxidation, Ceram. Int., 2018, 44(11), p 12978–12986. https://doi.org/10.1016/j.ceramint.2018.04.115

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gudala, S., Ramesh, M.R. & Nallathambi, S.S. Evolution of Microstructure and High-Temperature Tribological Performance of Self-Lubricating Nickel-Based Composite Tungsten Inert Gas Coatings. J. of Materi Eng and Perform 30, 8080–8094 (2021). https://doi.org/10.1007/s11665-021-06008-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-06008-4