Abstract

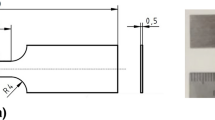

In this study, effect of cryogenic heat treatment in polycrystalline Co38Ni37Al17Si6Sb2 ferromagnetic shape memory alloy (FSMA) on phase formation phenomenon was investigated. After the homogenization process, the synthesized Co38Ni37Al17Si6Sb2 alloy was cooled into liquid nitrogen and kept in liquid nitrogen for different time periods. X-ray difraction method was used to determine lattice parameters and crystallite sizes from the samples obtained. The crystallite size of the Co38Ni37Al17Si6Sb2 alloy was calculated using the Debye Scherrer equation. The results show that these alloys were composed of four phases; A1 structure of γ phase, β austenite phase (B2 cubic), body-centered tetragonal L10 martensite and γ′ (ordered fcc L12) phase. Thermal properties of Co38Ni37Al17Si6Sb2 specimens were analyzed by Differential Scanning Calorimetry (DSC). Martensitic transformation temperatures were increased due to the increasing aging time in Liquid Nityrogen. An endothermic peak at ~ 165°C and an exothermic peak at ~ 110°C were observed from DSC results. Scattering Electron Microscope (SEM) and optical microscope experiments were performed to investigate metallographic structures. The findings of the γ, β and L10 phases were confirmed by SEM observations and EDS analysis. As a result of cryogenic heat treatment in the material phase formation phonomenon was discussed. Vickers and Rocwell Hardness methods were determined to find differences of hardness values due to the cryogenic heat treatment time on Co38Ni37Al17Si6Sb2 FSMA. The hardness value of the alloy has been found to rise with increasing cryogenic aging time.

Similar content being viewed by others

References

Z.H. Liu, X.F. Dai, Z.H. Zhu and J.L. Chen, Martensitic Transformation and Magnetic Properties of Co-Ni-Al Shape Memory Alloy Ribbons, Scripta Mater., 2004, 37, p 2643–3264.

J. Liu and J.G. Li, Magnetic Force Microscopy Observations of Co-Ni-Ga and Co-Ni-Al Alloys with Two-Phase Structures, Scripta Mater., 2006, 55, p 755–758.

A.Ç. Akis, “Şekil hatirlamali Co-Ni-Al-Si alaşiminda yaşlandirma olayinin martensitik faz dönüşümü üzerine etkileri,” Master Thesis, Kilis 7 Aralik University, Institute of Science, Kilis, 2012

J. Liu, H. Xie, Y. Huo, H. Zheng and J. Li, Microstructure Evolution in CoNiGa Shape Memory Alloys, J. Alloys Compd., 2006, 420, p 145–157.

A.K. Soğuksu, “Şekil hatirlamali Cu-Al-Ni ve Cu-Zn-Al alaşimlarin üretilmesi ve özelliklerinin incelenmesi,” Yüksek Lisans Tezi, KSÜ, Institute of Science, Kahramanmaraş, 2006

M. Eskil, E. Seval and A.Ç. Akis, Şekil hatirlamali alaşimlarinin kristalografik özellikleri, Erciyes Univ. J. Sci. Inst., 2014, 30(1), p 19–28.

S. Chatterjee, M. Thakur, S. Giri, S. Majumdar, A.K. Deb and S.K. Deuy, Transport, Magnetic and Structural Investigations of Co-Ni-Al Shape Memory Alloy, J. Alloys Compd., 2008, 456, p 96–100.

Y. Tanaka, K. Oikawa, Y. Sutou, T. Omori, R. Kainuma and K. Ishida, Martensitic Transition and Superalasticity of Co-Ni–Al Ferromagnetic Shape Memory Alloys with β + γ Two-Phase Structure, Mater. Sci. Eng. A, 2006, 438, p 1054–1060.

N. Ozbek, A. Çiçek, M. Gülesin, O. Özbek, Kriyojenik işlem uygulanmiş kaplamasiz WC-Co takimlarla AISI 304 paslanmaz çeliğin işlenmesinde yüzey pürüzlülüğü ve kesme kuvvetlerinin incelenmesi, International Conference on Engineering Tecnology and Applied Sciences, Afyon Kocatepe University, Turkey, 2016

J.Y. Huang, Y.T. Zhu, X.Z. Liao, I.J. Beyerlein, M.A. Bourke and T.E. Mitchell, Microstructure of Cryogenic Treated M2 Tool Steel, Mater. Sci. Eng. A, 2003, 339(2003), p 241–244.

R. Zhang, X. Zhang, M. Qian, J. Sun and L. Geng, Effect of Si Doping on Microstructure and Martensite Transformation in Ni-Mn-Sb Ferromagnetic shape memory alloys, Intermetallics, 2018, 97, p 1–7.

B.D. Cullity, Elements of X-Ray Diffraction, 2nd ed. Addison-Wesley Publishing Company Inc., Reading, MA, 1978, p 102

Z.N. Zhou, L. Yang, R.C. Li, J. Li, Q.D. Hu and J.G. Li, Martensitic Transformations and Kinetics in Ni-Mn-In-Mg Shape Memory Alloys, Intermetallics, 2018, 92, p 49.

J. Ortin and A. Planes, Thermodynamic Analysis of Thermal Measurements in Thermoelastic Martensitic Transformations, Acta Metall., 1988, 36, p 1873–1889.

C.S. Barrett and T.B. Massalski, Structure of Metals, Pergamon Press, Oxford, 1982.

K. Oikawa, T. Ota, F. Gejima, T. Ohmori, R. Kainuma and K. Ishida, Phase equilibria and Phase Transformations in New B2-type Ferromagnetic Shape Memory alloys of Co-Ni-Ga and Co-Ni-Al Systems, Mater. Trans., 2001, 42, p 2472.

J. Li and J. Li, Microstructure Evolution of the Undercooled Co–Ni-Ga Magnetic Shape Memory Alloy, J. Alloys Compd., 2011, 509, p 1563–1566.

Ju. Jia, F. Xue and H. Li, Microstructure and Magnetic Property Variation with Addition of Rare Earth Element Dy in Co-Ni-Al Ferromagnetic Shape Memory Alloy, J. Iron Steel Res. Int., 2015, 22(9), p 858–863.

Y.H. Lu, L.J. Qiao and W.Y. Chu, Characteristics of microcrack initiation in CuNiAl shape memory alloy, Fatigue Fract. Eng. Mater Struct., 2002, 25, p 509–518.

E. Toptaş and N. Akkuş, Şekil Hafizali Alaşimlar ve Endüstriyel Uygulamalari, J. Mach. Electr. Technol., 2007, 4, p 15–22.

H. Güngüneş, “Fe-%24.5Ni-%4.5Si alaşiminda austenit ve martensitik faz dönüşümleri üzerine çalişmalar,” Ph.D. Thesis, Kirikkale University, Institute of Science, Kirikkale, 2005

C.C. Aksu, O. Karaduman, İ Özkul and N. Ünlü, Modifying Thermal and Structural Characteristics of CuAlFeMn Shape Memory Alloy and a Hypothetical Analysis to Optimize Surface-Diffusion Annealing Temperature, J. Mater. Eng. Perform., 2020, 2020(29), p 7993–8005.

C.C. Aksu, O. Karaduman, N. Ünlü, S.B. Aziz and İ Özkul, Heat Treatment and Quenching Media Effects on the Thermodynamical, Thermoelastical and Structural Characteristics of a New Cu-BASED Quaternary Shape Memory Alloy, Compos. Part B-Eng. Compos. Part B, 2019, 174, p 106940.

Acknowledgments

This research has received funding from the Scientific Research Project Funds of Aksaray University (Bilimsel Araştirma Projeleri Koordinasyon Birimi (BAP)) under Grant No. 2015-066.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Eskil, M., Sahan, Z.A. Effect of Cryogenic Heat Treatment on Phase Formation in Co38Ni37Al17Si6Sb2 Ferromagnetic Shape Memory Alloy. J. of Materi Eng and Perform 30, 7283–7294 (2021). https://doi.org/10.1007/s11665-021-05930-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05930-x