Abstract

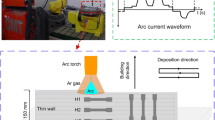

Wire arc additive manufacturing (WAAM) is the latest development in 3D printing because of its high build rate. This study investigated the first use of cable-type welding wire (CWW) to manufacture thin-walled AA5356 aluminum alloy through cold metal transfer technology. The inherent advantages of the CCW, such as high deposition efficiency, energy savings, and better stirring of the weld puddle due to arc rotation, were tapped and analyzed for WAAM. The experimental results showed that WAAM CWW provides enhanced quality built parts. The grain morphology, phase in micro-constituents, and defect formation were investigated through structured optical micrography and XRD analyses. The mechanical test was also performed along and normal to the build direction. The optical microscopy results showed that a defect free deposit with equiaxed grains was formed. Compared with the casting aluminum alloy, the average ultimate tensile strength and yield strength of the parts made by the WAAM with CWW increased by 19.8% and 22.5%, respectively.

Similar content being viewed by others

References

D.D. Gu, W. Meiners, K. Wissenbach and R. Poprawe, Laser Additive Manufacturing of Metallic Components: Materials, Processes and Mechanisms, Int. Mater. Rev., 2013, 57(3), p 133–164.

W.E. Frazier, Metal Additive Manufacturing: A Review, J. Mater. Eng. Perform., 2014, 23(6), p 1917–1928.

B. Cheng, L. Loeber, H. Willeck, U. Hartel and C. Tuffile, Computational Investigation of Melt Pool Process Dynamics and Pore Formation in Laser Powder Bed Fusion, J. Mater. Eng. Perform., 2019, 28(11), p 6565–6578.

M.H. Farshidianfar, A. Khajepour and A.P. Gerlich, Effect of Real-Time Cooling Rate on Microstructure in Laser Additive Manufacturing, J. Mater. Process. Technol., 2016, 231, p 468–478.

C.A. Brice, B.T. Rosenberger, S.N. Sankaran, K.M. Taminger, B. Woods and R. Nasserrafi, Chemistry Control in Electron Beam Deposited Titanium Alloys, Mater. Sci. Forum, 2009, 618–619, p 155–158.

Y. Ma, D. Cuiuri, N. Hoye, H. Li and Z. Pan, The Effect of Location on the Microstructure and Mechanical Properties of titanium Aluminides Produced by Additive Layer Manufacturing using In-situ Alloying and Gas Tungsten Arc Welding, Mater. Sci. Eng. A, 2015, 631, p 230–240.

R. Tangestani, G.H. Farrahi, M. Shishegar, B.P. Aghchehkandi, S. Ganguly and A. Mehmanparast, Effects of Vertical and Pinch Rolling on Residual Stress Distributions in Wire and Arc Additively Manufactured Components, J. Mater. Eng. Perform., 2020, 29(4), p 2073–2084.

X.Z. Chen, C.C. Su, Y.F. Wang, A.N. Siddiquee, K. Sergey, S. Jayalakshmi and R.A. Singh, Cold Metal Transfer (CMT) Based Wire and Arc Additive Manufacture (WAAM) System, J. Surf. Investig. X-Ray Synchrotron Neutron Tech., 2019, 12(6), p 1278–1284.

S.W. Williams, F. Martina, A.C. Addison, J. Ding, G. Pardal and P. Colegrove, Wire + Arc Additive Manufacturing, Mater. Sci. Technol., 2016, 32(7), p 641–647.

C.C. Su, X.Z. Chen, C. Gao and Y.F. Wang, Effect of Heat Input on Microstructure and Mechanical Properties of Al-Mg Alloys Fabricated by WAAM, Appl. Surf. Sci., 2019, 486, p 431–440.

C. Zhang, Y. Li, M. Gao and X. Zeng, Wire Arc Additive Manufacturing of Al-6Mg Alloy Using Variable Polarity Cold Metal Transfer Arc as Power Source, Mater. Sci. Eng. A, 2018, 711, p 415–423.

L. Wang, Y. Suo, Z. Liang, D. Wang and Q. Wang, Effect of Titanium Powder on Microstructure and Mechanical Properties of Wire + Arc Additively Manufactured Al-Mg Alloy, Mater. Lett., 2019, 241, p 231–234.

Y. Chen, C. Fang, Z. Yang, J. Wang, M. Wu and S. Chen, A Study on Sidewall Penetration of Cable-Type Welding Wire Electrogas Welding, Weld. World, 2017, 61(5), p 979–986.

Y. Chen, C. Fang, Z. Yang, J. Wang, G. Xu and X. Gu, Cable-Type Welding Wire arc Welding, Int. J. Adv. Manuf. Technol., 2017, 94(1–4), p 835–844.

Z. Yang, C. Fang, Y. Chen, B. Liu, Q. Hu and X. Gu, Effect of Forces on Dynamic Metal Transfer Behavior of Cable-Type Welding Wire Gas Metal Arc Welding, Int. J. Adv. Manuf. Technol., 2018, 97(1–4), p 81–90.

C. Fang, Y. Chen, Z. Yang, J. Wang, M. Wu and K. Qi, Cable-Type Welding Wire Submerged Arc Surfacing, J. Mater. Process. Technol., 2017, 249, p 25–31.

Y. Liang, S. Hu, J. Shen, H. Zhang and P. Wang, Geometrical and Microstructural Characteristics of the TIG-CMT Hybrid Welding in 6061 Aluminum Alloy Cladding, J. Mater. Process. Technol., 2017, 239, p 18–30.

M. Köhler, J. Hensel and K. Dilger, Effects of Thermal Cycling on Wire and Arc Additive Manufacturing of Al-5356 Components, Metals, 2020, 10(7), p 952.

S. Li, L.-J. Zhang, J. Ning, X. Wang, G.-F. Zhang, J.-X. Zhang, S.-J. Na and B. Fatemeh, Comparative Study on the Microstructures and Properties of Wire+Arc Additively Manufactured 5356 Aluminium Alloy with Argon and Nitrogen as the Shielding Gas, Addit. Manuf., 2020, 34, p 101206.

T.X. Gao, H.M. Liu, F.Y. Wang and Y. Chen, Effect of Ce on the Microstructure and Mechanical Properties of 5356 Aluminum Alloy, Mater. Sci. Technol., 2016, 24(3), p 34–39.

W. Zuo, L. Ma, Y. Lu, S.Y. Li, Z.Q. Ji and M. Ding, Effects of Solution Treatment Temperatures on Microstructure and Mechanical Properties of TIG-MIG Hybrid Arc Additive Manufactured 5356 Aluminum Alloy, Met. Mater. Int., 2018, 24(6), p 1346–1358. ((in English))

Q.P. Zhong and Z.H. Zhao, Fractography, Higher Education Press, Beijing, 2006.

I. Westermann, K.O. Pedersen, T. Furu, T. Børvik and O.S. Hopperstad, Effects of Particles and Solutes on Strength, Work-Hardening and Ductile Fracture of Aluminium Alloys, Mech. Mater., 2014, 79, p 58–72.

Acknowledgements

This project is supported by National Natural Science Foundation of China (Grant No. 51975419).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, J., Shen, Q., Kong, X. et al. Arc Additively Manufactured 5356 Aluminum Alloy with Cable-Type Welding Wire: Microstructure and Mechanical Properties. J. of Materi Eng and Perform 30, 7472–7478 (2021). https://doi.org/10.1007/s11665-021-05905-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05905-y