Abstract

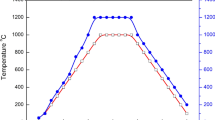

The billets of 2A12 aluminum alloy were prepared by a novel method called semisolid isothermal treatment of hot-rolled aluminum alloy (SSITHRAA). The spheroidizing process of elongated grains during temperature rising stage and semisolid isothermal treatment stage was investigated. The results showed that recrystallization degree increased with the increase in temperature or time. Appreciable recrystallization happened above 520 °C and even occurred in the semisolid region. Deformation textures (Brass and Copper) and recrystallization texture (Cube) were found in the microstructure at 580 °C. The semisolid isothermal treatment temperature and holding time had greatly influenced the grain morphologies. Average grain size increased with holding time or heating temperature in the proper range of 590-620 °C for 5-30 min generally. The spheroidization degree increased firstly and then decreased with time. Under the optimized condition of 620 °C and 25 min, near globular grains with average diameter (D) of 105 μm and roundness (R) of 1.24 were obtained. The fitting degree of coarsening kinetics curves showed slight differences among various exponents, and the grain growth constants ranged from 370 to 657 μm3/s with n = 3. Based on the principle of minimum Gibbs free energy, the whole processing could be explained from the point of thermodynamics and kinetics. EDS showed that eutectic phases rich in Cu and precipitates containing Fe appeared at the grain boundaries.

Similar content being viewed by others

References

D.B. Spencer, R. Mehrabian, and M.C. Flemings, Rheological Behavior of Sn-15 pct Pb in the Crystallization Range, Metall. Trans. A, 1972, 3, p 1925–1932.

S.B. Hassas-Irani, A. Zarei-Hanzaki, B. Bazaz, and A.A. Roostaei, Microstructure Evolution and Semi-Solid Deformation Behavior of an A356 Aluminum Alloy Processed by Strain Induced Melt Activated Method, Mater. Des., 2013, 46, p 579–587.

S. Ashouri, M. Nili-Ahmadabadi, M. Moradi, and M. Iranpour, Semi-Solid Microstructure Evolution During Reheating of ALUMINUM A356 Alloy Deformed Severely by ECAP, J. Alloys Compd., 2008, 466, p 67–72.

M.C. Flemings, Behavior of Metal Alloys in the Semisolid State, Metall. Trans. B, 1991, 22, p 957–981.

S. Chayong, H.V. Atkinson, and P. Kapranos, Thixoforming 7075 Aluminium Alloys, Mater. Sci. Eng. A, 2005, 390, p 3–12.

Z.Z. Chen, Preparation of Semi-Solid A356 Al-Alloy Slurry by Introducing Grain Process, Trans. Nonferrous Met. Soc. China, 2012, 22, p 1307–1312.

J. Dong, J.Z. Cui, and W.J. Ding, Theoretical Discussion of the Effect of a Low-Frequency Electromagnetic Vibrating Field on the as-Cast Microstructures of DC Al–Zn–Mg–Cu–Zr Ingots, J. Cryst. Growth., 2006, 295, p p179-187.

J.F. Jiang, Y. Zhang, Y. Wang, G.F. Xiao, Y.Z. Liu, and L. Zeng, Microstructure and Mechanical Properties of Thixoforged Complex Box-Type Component of 2A12 Aluminum Alloy, Mater. Des., 2020 https://doi.org/10.1016/j.matdes.2020.108859

J. Jiang, Y. Liu, G. Xiao, Y. Wang, and X. Xiao, Effects of Plastic Deformation of Solid Phase on Mechanical Properties and Microstructure of Wrought 5A06 Aluminum Alloy in Directly Semisolid Thixoforging, J. Alloys Compd., 2020 https://doi.org/10.1016/j.jallcom.2020.154748

R. Haghayeghi, E.J. Zoqui, A. Halvaee, and M. Emamy, An Investigation on Semi-solid Al–7Si–0.3Mg Alloy Produced by Mechanical Stirring, J. Mater. Process. Technol., 2005, 169, p 382–387.

C.G. Kang, J.W. Bae, and B.M. Kim, The Grain Size Control of A356 Aluminum Alloy by Horizontal Electromagnetic Stirring for Rheology Forging, J. Mater. Process. Technol., 2007, 187–188, p 344–348.

Y. Birol, A357 Thixoforming Feedstock Produced by Cooling Slope Casting, J. Mater. Process. Technol., 2007, 186, p 94–101.

H.V. Atkinson, and D. Liu, Microstructural Coarsening of Semi-Solid Aluminium Alloys, Mater. Sci. Eng. A, 2008, 496, p 439–446.

G.H. Yan, S.D. Zhao, S.Q. Ma, and H.T. Shou, Microstructural Evolution of A356.2 Alloy Prepared by the SIMA Process, Mater. Charact., 2012, 69, p 45–51.

E. Parshizfard, and S.G. Shabestari, An Investigation on the Microstructural Evolution and Mechanical Properties of A380 Aluminum Alloy During SIMA Process, J. Alloys Compd., 2011, 509, p 9654–9658.

J.C. Choi, and H.J. Park, Microstructural Characteristics of Aluminum 2024 by Cold Working in the SIMA Process, J. Mater. Process. Technol., 1998, 82, p 107–116.

A. Bolouri, M. Shahmiri, and E.N.H. Cheshmeh, Microstructural Evolution During Semisolid State Strain Induced Melt Activation Process of Aluminum 7075 Alloy, Trans. Nonferrous Met. Soc. China, 2010, 20, p 1663–1671.

J.F. Jiang, Y. Wang, G.F. Xiao, and X. Nie, Comparison of Microstructural Evolution of 7075 Aluminum alloy Fabricated by SIMA and RAP, J. Mater. Process. Technol., 2016, 238, p 361–372.

M.R. Rokni, A. Zarei-Hanzaki, H.R. Abedi, and N. Haghdadi, Microstructure Evolution and Mechanical Properties of Backward Thixoextruded 7075 Aluminum Alloy, Mater. Des., 2012, 36, p 557–563.

H.V. Atkinson, Modelling the Semisolid Processing of Metallic Alloys, Prog. Mater. Sci., 2005, 50, p 341–412.

J.F. Jiang, G.F. Xiao, Y. Wang, and Y.S. Qi, Microstructure Evolution of Wrought Nickel Based Superalloy GH4037 in the Semi-Solid State, Mater. Charact., 2018, 141, p 229–237.

Z.D. Zhao, Q. Chen, Z.J. Tang, and C.K. Hu, Microstructural Evolution and Tensile Mechanical Properties of AM60B Magnesium Alloy Prepared by the SIMA Route, J. Alloys Compd., 2010, 497, p 402–411.

B. Binesh and M. Aghaie-Khafri, RUE-Based Semi-Solid Processing: Microstructure Evolution and Effective Parameters, Mater. Des., 2016, 95, p 268–286.

H.J. Zhang, X.H. Zhao, D.S. Xu, Y. Liu, and X.M. Qiu, New Insight into High Frequency Impacting and Rolling of 2A12 aluminum Welded Joint Involving Nanocrystallization, Appl. Surf. Sci., 2019, 488, p 115–127.

J.H. Chen, W.F. Xu, R.Z. Xie, F.J. Zhang, W.J. Hu, X.C. Huang and G. Chen, Sample Size Effect on the Dynamic Torsional Behaviour of the 2A12 Aluminium Alloy, Theor. Appl. Mech. Lett., 2017, 7, p 317–324.

P.K. Seo and C.G. Kang, The Effect of Raw Material Fabrication Process on Microstructural Characteristics in Reheating Process for Semi-Solid Forming, J. Mater. Process. Technol., 2005, 162–163, p 402–409.

K. Huang and R.E. Logé, A Review on Dynamic Recrystallization Phenomena in Metallic Materials, Mater. Des., 2016, 111, p 548–574.

G.F. Xiao, J.F. Jiang, Y.Z. Liu, Y. Wang and B.Y. Guo, Recrystallization and Microstructure Evolution of hot Extruded 7075 Aluminum Alloy During Semi-Solid Isothermal Treatment, Mater. Charact., 2019 https://doi.org/10.1016/j.matchar.2019.109874

M.N. Gussev and K.J. Leonard, In situ SEM-EBSD Analysis of Plastic Deformation Mechanisms in Neutron-Irradiated Austenitic Steel, J. Nucl. Mater., 2019, 517, p 45–56.

H.V. Atkinson, K. Burke and G. Vaneetveld, Recrystallisation in the Semi-Solid State in 7075 Aluminium Alloy, Mater. Sci. Eng. A, 2008, 490, p 266–276.

A. Bolouri, M. Shahmiri and C.G. Kang, Study on the Effects of the Compression Ratio and Mushy Zone Heating on the Thixotropic Microstructure of AA 7075 Aluminum Alloy via SIMA Process, J. Alloys Compd., 2011, 509, p 402–408.

D. Fan, S.P. Chen, L.Q. Chen and P.W. Voorhees, Phase-Field Simulation of 2-D Ostwald Ripening in the High Volume Fraction Regime, Acta Mater., 2002, 50, p 1895–1907.

E. Tzimas and A. Zavaliangos, Evolution of Near-Equiaxed Microstructure in the Semisolid State, Mater. Sci. Eng. A, 2000, 289, p 228–240.

G. Chen, T. Zhou, B. Wang, H.W. Liu and F. Han, Microstructure Evolution and Segregation Behavior of Thixoformed Al–Cu–Mg–Mn Alloy, Trans. Nonferrous Met. Soc. China, 2016, 26, p 39–50.

H. Mohammadi, M. Ketabchi and A. Kalaki, Microstructure Evolution of Semi-Solid 7075 Aluminum Alloy During Reheating Process, J. Mater. Eng. Perform., 2011, 20, p 1256–1263.

J.F. Jiang, Y. Wang and H.V. Atkinson, Microstructural Coarsening of 7005 Aluminum Alloy Semisolid Billets with High Solid Fraction, Mater. Charact., 2014, 90, p 52–61.

N. Wang, Z.M. Zhou and G.M. Lu, Microstructural Evolution of 6061 Alloy During Isothermal Heat Treatment, J. Mater. Sci. Technol., 2011, 27, p 8–14.

M. Kiuchi and R. Kopp, Mushy/Semi-Solid Metal Forming Technology–Present and Future, CIRP Ann. Manuf. Technol., 2002, 51, p 653–670.

I.M. Lifshitz and V.V. Slyozov, The Kinetics of Precipitation from Supersaturated Solid Solutions, J. Phys. Chem. Solids, 1961, 19, p 35–50.

C. Wagner, Theory of the Ageing of Precipitates by Redissolution (Ostwald Maturing), Electrochemistry, 1961, 65, p 581–591.

A. Bolouri, M. Shahmiri and C.G. Kang, Coarsening of Equiaxed Microstructure in the Semisolid state of Aluminum 7075 Alloy Through SIMA Processing, J. Mater. Sci., 2012, 47, p 3544–3553.

L. Jin, K. Kai, W. Wang, K. Xiao and H. Zhang, Microstructure Evolution and Thixoforming Behavior of 7075 Aluminum Alloy in the Semi-Solid State Prepared by RAP Method, Int. J. Miner. Metall. Mater., 2016, 23, p p1404-1415.

H.V. Atkinson and D. Liu, Coarsening Rate of Microstructure in Semi-Solid Aluminium Alloys, Trans. Nonferrous Met. Soc. China, 2010, 20, p 1672–1676.

J. Fu, S. Wang and K. Wang, Influencing Factors of the Coarsening Behaviors for 7075 Aluminum Alloy in the Semi-Solid State, J. Mater. Sci., 2018, 53, p 9790–9805.

X.F. Xu, Y.G. Zhao, B.D. Ma, J.T. Zhang and M. Zhang, Rapid Grain Refinement of 2024 Al Alloy Through Recrystallization Induced by Electropulsing, Mater. Sci. Eng. A, 2014, 612, p 223–226.

G.H. Li, L. Zhou, L.Y. Luo, X.M. Wu and N. Guo, Microstructural Evolution and Mechanical Properties of Refill Friction Stir Spot Welded Alclad 2A12-T4 Aluminum Alloy, J. Mater. Res. Technol., 2019, 8, p 4115–4129.

H.M. Guo, X.J. Yang and M. Zhang, Microstructure Characteristics and Mechanical Properties of Rheoformed Wrought Aluminum Alloy 2024, Trans. Nonferrous Met. Soc. China, 2008, 18, p 555–561.

L. Zhang, W. Li and J.P. Yao, Microstructures and Thermal Stability of the Semi-Solid 2024 Aluminum Alloy Prepared Using The Pulsed Magnetic Field Process: Effects of Technological Parameters, J. Alloys Compd., 2013, 554, p 156–161.

F. Zhang, Y.L. Kang, L.Q. Yang and R.H. Ding, Taper Barrel Rheomoulding Process for Semi-Solid Slurry Preparation and Microstructure Evolution of A356 Aluminum Alloy, Trans. Nonferrous Met. Soc. China, 2010, 20, p 1677–1684.

W.Z. Zhu, W.M. Mao and Q. Tu, Preparation of Semi-Solid 7075 Aluminum Alloy Slurry by Serpentine Pouring Channel, Trans. Nonferrous Met. Soc. China, 2014, 24, p 954–960.

J.X. Li, T. Zhai, M.D. Garratt and G.H. Bray, Four-Point-Bend Fatigue of AA 2026 Aluminum Alloys, Metall. Trans. A, 2005, 36, p 2529–2539.

Acknowledgment

This work is supported by the National Key Research and Development Program under Grant No. 2019YFB2006500 and the National Natural Science Foundation of China (NSFC) under Grant No. 51875124.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jiang, J., Zhang, Y., Wang, Y. et al. Spheroidizing Process of 2A12 Aluminum Alloy Grains during Heating up and Semisolid Isothermal Treatment Stages. J. of Materi Eng and Perform 30, 5974–5986 (2021). https://doi.org/10.1007/s11665-021-05796-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05796-z