Abstract

The hot salt stress corrosion cracking (HSSCC) behavior of the selectively laser melted (SLM) Ti-6Al-4V alloy in the as-built and heat-treated conditions was studied at 300 and 400 °C. The HSSCC resistance of very susceptible as-built alloy can be significantly increased through annealing at 750 °C, losing only a small amount of ultimate tensile strength (UTS). The improvement in the HSSCC resistance is brought out by a transformation of martensite into lamellar α + β. The absence of equiaxed α found in the wrought alloy seems to help in increasing the HSSCC resistance of SLM Ti-6Al-4V alloy at high strength level.

Similar content being viewed by others

References

P. Chandramohan, S. Bhero, B.A. Obadele and P.A. Lobamba, Laser Additive Manufactured Ti-6Al-4V Alloy: Tribology and Corrosion Studies, Int. J. Adv. Manuf. Tech., 2017, 92, p 3051–3061.

P. Chandramohan, S. Bhero, F. Varachia, B.A. Obadele and P.A. Olubambi, Laser Additive Manufactured Ti-6Al-4V Alloy: Heat Treatment Studies, T. Indian I. Metals, 2018, 71, p 579–587.

R. Silverstein and D. Eliezer, Hydrogen Trapping in 3-D Printing (Additively Manufactured) Ti-6Al-4V Alloy, Mater. Charact., 2018, 144, p 297–304.

J. Sun, X. Zhu, L. Qiu, F. Wang, Y. Yang and L. Guo, The Microstructure Transformation of Selective Laser Melted Ti-6Al-4V Alloy, Mater. Today Commun., 2019, 19, p 277–285.

S. Liu and Y.C. Shin, Additive Manufacturing of Ti6Al4V Alloy: A Review, Mater. Des., 2019, 164, p 107552.

C. Leyens and M. Peters, Titanium and Titanium Alloys-Fundamentals and Applications, Wiley , Weinheim, Germany, 2006, p 12

H. Galarraga, R.J. Warren, D.A. Lados, R.R. Dehoff, M.M. Kirka and P. Nandwana, Effects of Heat Treatments on Microstructure and Properties of Ti-6Al-4V ELI Alloy Fabricated by Electron Beam Melting (EBM), Mater. Sci. Eng. A, 2017, 685, p 417–428.

X. Yan, S. Yin, C. Chen, C. Huang, R. Bolot, R. Lupoi, M. Kuang, W. Ma, C. Coddet, H. Liao and M. Liu, Effect of Heat Treatment on the Phase Transformation and Mechanical Properties of Ti6Al4V Fabricated by Selective Laser Melting, J. Alloys and Compd., 2018, 764, p 1056–1071.

R.L. Kirchner and E.J. Ripling, Elevated Temperature Stress Corrosion of High Strength Sheet Materials in the Presence of Stress Concentrators, NASA First Interm Report N65-82069, 1964.

M.W. Mahoney and A.S. Tetelman, The Effect of Microstructure on the Hot Salt Stress Corrosion Susceptibility of Titanium Alloys, Metall. Trans., 1976, 7A, p 1549–1558.

J.D. Jackson and W.K. Boyd, The Stress-Corrosion and Accelerated Crack-Propagation Behaviour of Titanium and Titanium Alloys, DMIC Technical Note, Ohio, 1966.

H.R. Gray, Hot Salt Stress Corrosion Cracking of Titanium alloys: Generation of Hydrogen and Its Embrittling Effect, NASA Technical note TN D-5000, 1969.

H.R. Gray and J.R. Johnston, Hot-Salt Stress-Corrosion of Titanium Alloy in a Dynamic Air Environment, Metall. Trans., 1970, 1, p 3101–3105.

J.R. Myers and J.A. Hall, Hot-Salt Stress-Corrosion Cracking of Titanium Alloys: An Improved Model for the Mechanism, Corrosion-NACE, 1977, 33, p 252–257.

R.K. Dinnappa, Hot Salt Stress Corrosion Cracking of a Titanium Alloy: The Phenomenon in View of Aero Gas Turbine Operating Condition, Key Eng. Mater., 1988, 20–28, p 2255–2271.

T. Chevrot, Pressure effect on hot salt stress corrosion cracking of titanium alloys, PhD Thesis, Cranfield University, 1994.

S.P. Rideout, M.R. Louthan Jr. and C.L. Selby, Basic Mechanisms of Stress-Corrosion Cracking of Titanium, ASTM STP, 1966, 397, p 137–151.

G.J. Heimerl, and D.M. Royster, Hot Salt Stress Corrosion Cracking of Sheet Materials for a Supersonic Transport, NASA Technical note N68-25324, 1967.

H.B. Dexter, Salt stress corrosion of residually stressed Ti-8Al-1Mo-1V alloy sheet after exposure at elevated temperatures, NASA TN D-3299, 1966.

V.C. Petersen, Hot Salt Stress Corrosion of Titanium-A Review of the Problem and Methods for Improving the Resistance of Titanium, J. Metals, 1971, 23, p 40–47.

D. Sinigaglia, G. Taccani and B. Vicentini, Hot Salt Stess Corrosion Cracking of Titanium Alloys, Corros. Sci., 1978, 18, p 781–796.

S. Joseph, T.C. Lindley, D. Dye and E.A. Saunders, The Mechanisms of Hot Salt Stress Corrosion Cracking in Titanium Alloys, Ti-6Al-2Sn-4Zr-6Mo, Corros. Sci., 2018, 134, p 169–178.

E.A. Saunders, T.P. Chapman, A.R.M. Walker, T.C. Lindley, R.J. Chater, V.A. Vorontsov, D. Rugg and D. Day, Understanding the “Blue Spot”: Sodium Chloride Hot Salt Stress-Corrosion Cracking in Titanium-6246 during Fatigue Testing at Low Pressure, Eng. Fail. Anal., 2016, 61, p 2–20.

R.G. Lingwall, and E.J. Ripling, Elevated Temperature Stress Corrosion of High Strength Sheet Materials in the Presence of Stress Concentrators, NASA Technical note CR-88979, 1967.

M. Garfinkle, An electrochemical model for hot salt stress corrosion cracking of titanium alloys, Metall. Trans., 1973, 4, p 1677–1686.

R.S. Ondrejcin, Hydrogen in Hot Salt Stress Corrosion Cracking of Titanium Aluminium Alloys, Metall. Trans., 1970, 1, p 3031–3036.

M.D. Pustode and V.S. Raja, Hot Salt Stress Corrosion Cracking Behaviour of Ti-6242S Alloy, Metall. Trans. A, 2015, 46, p 6081–6089.

M.D. Pustode, B. Dewangan, V.S. Raja, N. Paulose and N. Babu, Study of High Temperature Stress Corrosion Crack Initiation of Alloy IMI 834 by DC Potential drop Method, Corros. Sci. and Tech., 2016, 15, p 203–208.

A.J. Hatch, H.W. Rosenberg and E.F. Erbin, Effect of Environment on Cracking of Titanium Alloys, ASTM STP, 1966, 397, p 122–136.

R.S. Ondrejcin, C.L. Selby, and S.P. Rideout, Role of Chloride in Hot Salt Stress Corrosion Cracking of Titanium Aluminium Alloys, NASA Technical note CR-87817, 1967.

M. Encrenaz, P. Faure and J.A. Petit, Hot Salt Stress Corrosion Resistance of Ti-6246 Alloy, Corros. Sci., 1998, 40, p 939–950.

M.D. Pustode, V.S. Raja and N. Paulose, The Stress-Corrosion Cracking Susceptibility of near-α Titanium Alloy IMI 834 in Presence of Hot Salt, Corros. Sci., 2014, 82, p 191–196.

M.D. Pustode, B. Dewangan, V.S. Raja and N. Paulose, Effect of Long Term Exposure and Hydrogen Effects on HSSCC Behaviour of Titanium Alloy IMI 834, Mater. Des., 2015, 86, p 841–847.

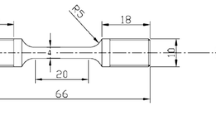

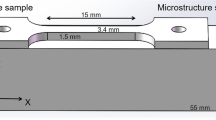

Standard test methods for tension testing of metallic materials, ASTM E8.

A. Khorasani, I. Gibson, M. Goldberg and G. Littlefair, The Role of Different Annealing Heat Treatments on Mechanical Properties and Microstructure of Selective Laser Melted and Conventional Wrought Ti-6Al-4V, Rapid Prototyp. J., 2017, 23, p 295–304.

M. Wang, Y. Wu, S. Lu, T. Chen, Y. Zhao, H. Chen and Z. Tang, Fabrication and Characterisation of Selective Laser Melting Printed Ti-6Al-4V Alloys Subjected to Heat Treatment for Customized Implants Design, Prog. Nat. Sci-Mater., 2016, 26, p 671–677.

G. Lütjering and J.C. Williams, Titanium, Springer, New York, NY, 2003, p 206

P. Yadroitsev, I. Krakhmalev and I. Yadroitsava, Selective Laser Melting of Ti6Al4V Alloy for Biomedical Applications: Temperature Monitoring and Microstructural Evolution, J. Alloys Compd., 2014, 583, p 404–409.

B. Baufeld, E. Brandl and O. Biest, Wire Based Additive Layer Manufacturing: Comparison of Microstructure and Mechanical Properties of Ti-6Al-4V Alloy Components Fabricated by Laser Beam Deposition and Shape Metal Deposition, J. Mater. Process Technol., 2011, 211, p 1146–1158.

L.E. Murr, S.A. Quinones, S.M. Gaytan, M.I. Lopez, A. Rodela, E.Y. Martinez, D.H. Hernandez, E. Martinez, F. Medina and R.B. Wicker, Microstructure and Mechanical Behavior of Ti-6Al-4V Produced by Rapid-Layer Manufacturing, for Biomedical Applications, J. Mech. Behav. Biomed. Mater., 2009, 2(1), p 20–32.

M. Niekter, P. Akerfeldt, R. Pederson and M.-L. Antti, Microstructural Characterisation of Ti-6Al-4V from Different Additive Manufacturing Processes, IOP Conf. Ser. Mater. Sci. Eng., 2017, 258, p 012007.

T. Ahmed and H.J. Rack, Phase Transformation during Cooling in α + β Titanium Alloys, Mater. Sci. Eng. A, 1998, 243, p 206–211.

F.R. Kaschel, R.K. Vijayaraghavan, A. Shmeliov, E.K. McCarthy, M. Canavan, P.J. McNally, D.P. Dowling, V. Nicolosi and M. Celikin, Mechanism of Stress Relaxation and Phase Transformation in Additively Manufactured Ti-6Al-4V Via in Situ High Temperature XRD and TEM Analysis, Acta. Mater., 2020, 188, p 720–732.

M.D. Pustode, V.S. Raja and M. Tamilselvi, The Stress Corrosion Cracking Susceptibility of Ti-6Al-4V Alloy in Presence of Hot Salt, Conference Proceeding, C2013-2157, Corrosion 2013, Orlando, USA.

D. Gu, W. Meiners, K. Wissenbach and R. Poprawe, Laser Additive Manufacturing of Metallic Components; Materials, Processes and Mechanisms, Int. Mater. Rev., 2012, 52, p 133–164.

ISO 7539-7:2005, Corrosion of Metals and Alloys, Stress Corrosion Testing, Part-7: Method for Slow Strain rate Testing

Acknowledgments

The authors thank Dr. Rajkumar Singh, Senior Director, KCTI- Bharat Forge Ltd for providing the SLM manufactured Ti-6Al-4V alloy for this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in theJournal of Materials Engineering and Performance on Additive Manufacturing. The issue was organized by Dr. William Frazier, Pilgrim Consulting, LLC; Mr. Rick Russell, NASA; Dr. Yan Lu, NIST; Dr. Brandon D. Ribic, America Makes; and Caroline Vail, NSWC Carderock.

Rights and permissions

About this article

Cite this article

Pustode, M.D., Chakraborty, P., Padekar, B.S. et al. Hot Salt Stress Corrosion Cracking Study of Selective Laser Melted Ti-6Al-4V Alloy. J. of Materi Eng and Perform 30, 5323–5332 (2021). https://doi.org/10.1007/s11665-021-05774-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05774-5