Abstract

A laser-welded Inconel 617 superalloy was thermally exposed at 750 °C for up to 7000 h. It was found that carbides (M23C6, M6C-type Ti(C,N)), topological close-packed (TCP) μ phase and γ' phase (Ni3Al) were formed in the laser welds of Inconel 617 during thermal exposure. The spherical γ' phase in laser-welded Inconel 617 coarsens due to Ostwald ripening, while it shows better thermal stability under long-term exposure at 750 °C. The relationship between the carbides (the globular M6C, the short rod-like M6C and the block-shaped M23C6 carbide) and the matrix γ is a cube-on-cube orientation, while the relationship between the long rod-like M6C carbide and matrix γ is a noncoherent orientation. An increase in the volume fraction and average diameter of the M23C6 and M6C carbides is controlled by the diffusion of C, Cr and Mo atoms. The precipitation of the block-shaped Mo-rich μ phase is promoted in the carbon-depleted region around the M6C carbide by the segregation of Co and Mo. The mass precipitation of the γ' phase, M6C carbide and M23C6 carbide results in an increase in the hardness and a significant drop in the impact toughness of the exposed welded metals after 7000 h of exposure.

Similar content being viewed by others

References

R. Krishna, S.V. Hainsworth, S.P. Gill, A. Strang and H.V. Atkinson, Topologically Close-Packed μ Phase Precipitation in Creep-Exposed Inconel 617 Alloy, Metall. Mater. Trans. A., 2013, 44, p 1419–1429.

R. Krishna, H.V. Atkinson, S.V. Hainsworth and P.G. Simon, Gamma Prime Precipitation, Dislocation Densities, and TiN in Creep-Exposed Inconel 617 Alloy, Metall. Mater. Trans. A., 2016, 47, p 178–193.

G. Yan, Z.B. Zhang, R.C. Zhou, S.F. Hou and B.H. Wang, Microstructure and Mechanical Properties of Alloy 617B, Trans. Nonferrous Nonferrous Met. Soc. China., 2015, 25, p 1106–1113.

Y. Guo, B.H. Wang and S.F. Hou, Aging Precipitation Behavior and Mechanical Properties of Inconel 617 Superalloy, Acta Metall. Sinica (Engl. Lett.), 2013, 26(3), p 307–312.

Y.Y. Liu, L.H. Zhu, R.Y. Zhou, J.J. Zhang, Z.R. Lu and L. Chen, Effect of Microstructure Evolution on Properties of Inconel 617B Alloy Welded Joint Creep Tested at 750 °C, Heat Treat. Met-UK, 2017, 42, p 62–67.

A.G. Mohammad and M. Mohsen, Effect of Long-Term Service Exposure on Microstructure and Mechanical Properties of Alloy 617, Mater. Des., 2011, 32(5), p 2695–2700.

W.J. Ren, F.G. Lu, P.L. Nie, R.J. Yang, X. Liu, K. Feng and Z.G. Li, Effects of the Long-time Thermal Exposure on the Microstructure and Mechanical Properties of Laser Weldings of Inconel 617, J. Mater. Process. Technol., 2017, 247, p 296–305.

J. Wang, L.Z. Zhou, L.Y. Sheng and J.T. Guo, The Microstructure Evolution and Its Effect on the Mechanical Properties of a Hot-Corrosion Resistant Ni-Based Superalloy During Long-Term Thermal Exposure, Mater. Des., 2012, 39, p 55–62.

H. Jiang, J.X. Dong and M.C. Zhang, Phase transformation of alloy 617B during 10000 h aging: An element redistribution-related process, J. Alloy Compd., 2018, 765, p 586–594.

H. Jiang, J.X. Dong and M.C. Zhang, The Characteristics of μ Phase Precipitated During 720 °C Long-Term Aging in Alloy 617B, J. Mater. Res. Technol., 2019, 8, p 2461–2465.

T.J. Chu, H.L. Xu, Z.G. Li and F.G. Lu, Investigation of Intrinsic Correlation Between Microstructure Evolution and Mechanical Properties for Nickel-Based Weld Metal, Mater. Des., 2019, 165, p 107595.

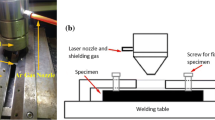

J.H. Sun, W.J. Ren, P.L. Nie, J. Huang, K. Zhang and Z.G. Li, Study on the Weldability, Microstructure and Mechanical Properties of Thick Inconel 617 Plate Using Narrow Gap Laser Welding Method, Mater. Des., 2019, 175, p 107823.

Y. Guo, Z.B. Zhang, R.C. Zhou, S.F. Hou and B.H. Wang, Microstructure and Mechanical Properties of Alloy 617B, T Nonferr Metal Soc., 2015, 25, p 1106–1113.

T. Liu, J.S. Dong, L. Wang, Z.J. Li, X.T. Zhou, L.H. Lou and J. Zhang, Effect of Long-Term Thermal Exposure on Microstructure and Stress Rupture Properties of GH3535 Superalloy, J. Mater. Sci. Technol., 2015, 31, p 269–279.

J. Liu, D. Jiao and C. Luo, Microstructural evolution in austenitic heat-resistant cast steel 35Cr25Ni12NNbRe during long-term service, Mater. Sci. Eng. A, 2010, 527, p 2772–2779.

S. Schröders, S. Sandlöbes, B. Berkels and S. Korte-Kerzel, On the Structure of Defects in the Fe7Mo6μ-Phase, Acta. Mater., 2019, 167, p 257–266.

A. Sarkar, P. Mukherjee, P. Barat, T. Jayakumar, S. Mahadevan and K.R. Sanjay, Lattice Misfit Measurement in Inconel 625 by X-Ray Diffraction Technique, Int. J. Mod. Phys. B, 2008, 22, p 1–20.

V.D. Divya, U. Ramamurty and A. Paul, Topological Close Packed μ Phase Formation and the Determination of Diffusion Parameters in the Co–Mo System, Intermetallics, 2010, 18, p 259–266.

D. Wang, J. Zhang and L.H. Lou, On the Role of Phase During High Temperature Creep of a Second Generation Directionally Solidified Superalloy, Mat Sci Eng A-Struct, 2010, 527, p 5161–5166.

B.C. Peng, H.X. Zhang, J. Hong, J.Q. Gao, Q.J. Wang and H.Q. Zhang, Effect of Aging on the Impact Toughness of 25Cr–20Ni–Nb–N steel, Mater. Sci. Eng. A, 2010, 527, p 1957–1961.

Acknowledgments

The authors acknowledge funding from National Natural Science Foundation of China (No. 51805483 51775338 and 51905343) and China's Post-doctoral Science Fund (No. 2019M651461).

Author information

Authors and Affiliations

Contributions

WR contributed to writing—original draft, YC was involved in data curation, investigation, LL contributed to methodology. FL was involved in funding acquisition, formal analysis, ZL contributed to supervision.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ren, W., Chen, Y., Lan, L. et al. Thermal Exposure Effect on the Microstructural and Mechanical Properties of a Laser-Welded Inconel 617 Joint in an Air Environment. J. of Materi Eng and Perform 30, 4328–4340 (2021). https://doi.org/10.1007/s11665-021-05747-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05747-8