Abstract

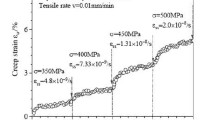

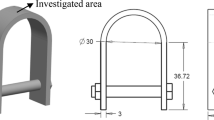

The purpose of this paper was to study the failure behavior of SUS304 stainless steel in view of cooling water leakage in actual service conditions. The temperature field and thermal stress distribution in the thickness direction of SUS304 stainless steel under actual service conditions were further analyzed by the finite element method. The results show that chromium-rich carbides are precipitated at the grain boundaries, which may cause intergranular corrosion. The morphology of the corrosion grooves is ditch structure, which has high intergranular corrosion susceptibility. The expansion direction of the cracks is from the contact surface of cooling water to the high-temperature contact surface. Fracture is characterized by a river pattern and rock candy pattern. Fracture morphology is characterized by brittle rupture. The Cl contained in the corrosion products comes from the circulating cooling water. XRD patterns show that the corrosion products are composed of CaCO3 (the high-temperature contact surface) and Fe3O4 (the contact surface of cooling water), respectively. EDS results of corrosion products are consistent with XRD results. The results of finite element simulation show that the temperature field along the thickness direction of SUS304 stainless steel plate is in the range of 436.6-450 °C. The peak of thermal stress is located in the middle of cross section. The cause of failure is acceleration of the initiation and extension of the cracks under the combined action of chloride ion stress corrosion, intergranular corrosion, and thermal stress. The form of crack fracture is mixture of transgranular and intergranular fracture, mainly transgranular fracture, which belongs to typical chloride ion stress corrosion.

Similar content being viewed by others

References

K.H. Lo, C.H. Shek and J.K.L. Lai, Recent Developments in Stainless Steels, Mater. Sci. Eng. R, 2009, 65, p 39–104.

M. Szala, K. Beer-Lech and M. Walczak, A Study on the Corrosion of Stainless Steel Floor Drains in an Indoor Swimming Pool, Eng. Fail. Anal., 2017, 77, p 31–38.

F. Iacoviello, V. Di Cocco and L. D’Agostino, Analysis of the Intergranular Corrosion Susceptibility in Stainless Steel by Means of Potentiostatic Reactivation Tests, Proc. Struct. Integr., 2017, 3, p 269–275.

E. Mohammadi Zahrani, Premature Failure of Grade-316Ti Stainless Steel Tubing in a Boiler Feed-Water Heat Exchanger in a Steel Complex, J. Failure Anal. Prevent., 2021, 21, p 61–73.

H. Sahlaoui, K. Makhlouf, H. Sidhom and J. Philibert, Effects of Ageing Conditions on the Precipitates Evolution, Chromium Depletion and Intergranular Corrosion Susceptibility of AISI 316l: Experimental and Modeling Results, Mater. Sci. Eng., A, 2004, 372, p 98–108.

Y. Gao, C.L. Zhang, X.H. Xiong, Z.H. Zheng and M. Zhu, Intergranular Corrosion Susceptibility of a Novel Super304H Stainless Steel, Eng. Fail. Anal., 2012, 24, p 26–32.

D.T. Spencer, M.R. Edwards, M.R. Wenman, C. Tsitsios, G.G. Scatigno and P.R. Chard-Tuckey, The Initiation and Propagation of Chloride-Induced Transgranular Stress-Corrosion Cracking (TGSCC) of 304L Austenitic Stainless Steel Under Atmospheric Conditions, Corros. Sci., 2014, 88, p 76–88.

R. Schoell, L. Xi, Y.C. Zhao, X. Wu, Z.Z. Yu, P. Kenesei, J. Almer, Z. Shayer, D. Kaoumi, In Situ Synchrotron X-Ray Tomography of 304 Stainless Steels Undergoing Chlorine-Induced Stress Corrosion Cracking, Corrosion Science, 2020, 170, Article 108687.

T.M. Ahmed, A. Alfantazi, J. Budac and G. Freeman, Failure Analysis of 316L Stainless Steel Tubing of the High-Pressure Still Condenser, Eng. Fail. Anal., 2009, 16, p 1432–1441.

S.J. Pawel, J.R. DiStefano and E.T. Manneschmidt, Thermal Gradient Mass Transfer of Type 316L Stainless Steel and Alloy 718 in Flowing Mercury, J. Nucl. Mater., 2001, 296, p 210–218.

G. Dini, M.H. Bina, S.M.M. Vaghefi, K. Raeissi, M. Safaei-Rad and M. Navabi, Failure of a Continuous-Annealing Furnace Roller at Mobarakeh Steel Company, Eng. Fail. Anal., 2008, 15, p 856–862.

M.J. Zhan, G.F. Sun, Z.D. Wang, X.T. Shen, Y. Yan and Z.H. Ni, Numerical and Experimental Investigation on Laser Metal Deposition as Repair Technology for 316L Stainless Steel, Opt. Laser Technol., 2019, 118, p 84–92.

J.S. Lu, H.F. Xuan and J. Xue, Failure Analysis of a 304 Stainless Steel Flange, Advanced Materials Research, 2015, 1120–1121, p 1024–1028.

Standard practice for detecting susceptibility to intergranular attack in austenitic stainless steels, American Society for Testing and Materials, ASTM A262(2015).

E. Mohammadi Zahrani, A. Saatchi, A. Alfantazi, Pitting of 316L Stainless Steel in Flare Piping of a Petrochemical Plant, Engineering Failure Analysis, 2010, 17, p 810-817.

D. Deng and H. Murakawa, Numerical Simulation of Temperature Field and Residual Stress in Multi-Pass Welds In Stainless Steel Pipe and Comparison with Experimental Measurements, Comput. Mater. Sci., 2006, 37, p 269–277.

D. Deng, H. Murakawa and W. Liang, Numerical and Experimental Investigations on Welding Residual Stress in Multi-Pass Butt-Welded Austenitic Stainless Steel Pipe, Comput. Mater. Sci., 2008, 42(2), p 234–244.

X.Y. Zhong, S.C. Bali and T. Shoji, Effects of Dissolved Hydrogen and Surface Condition on the Intergranular Stress Corrosion Cracking Initiation and Short Crack Growth Behavior of Non-Sensitized 316 Stainless Steel in Simulated PWR Primary Water, Corros. Sci., 2017, 118, p 143–157.

C. García, F. MartíN, P.D. Tiedra, J.A. Heredero and M.L. Aparicio, Effects of Prior Cold Work and Sensitization Heat Treatment on Chloride Stress Corrosion Cracking in Type 304 Stainless Steels, Corros. Sci., 2001, 43(43), p 1519–1539.

Standard test methods for determining average grain size, American Society for Testing and Materials, ASTM E112(2013).

K. Kaneko, T. Fukunaga, K. Yamada, N. Nakada, M. Kikuchi, Z. Saghi, J.S. Barnard and P.A. Midgley, Formation of M23C6-Type Precipitates and Chromium-Depleted Zones in Austenite Stainless Steel, Scripta Mater., 2011, 65(5), p 509–512.

X.W. Zhang, J.Q. Tang, H. Liu, J.M Gong, Effects of Pre-strain on Sensitization and Interganular Corrosion for 304 Stainless Steel, Engineering Failure Analysis, 2019, 106, Article 104179.

Corrosion of Metals and Alloys - Test Methods for Intergranular Corrosion of Austenitic and Ferritic-Austenitic (Duplex)Stainless Steels, GB/T 4334-2020, GB, 2020.

S.H. Zhang, Alloy steel, Beijing: Metallurgical Industry Press, 1981, p 28, in chinese.

S. Hu, Y.Z. Mao, X.B. Liu, E.H. Han, H. Hänninenad, Intergranular Corrosion Behavior of Low-chromium Ferritic Stainless Steel without Cr-carbide Precipitation After Aging, Corros. Sci., 2020, 166, Article 108420.

E. García-Ochoa, G. González-Sánchez, N. Acuña and J. Euan, Analysis of the Dynamics of Intergranular Corrosion Process of Sensitised 304 Stainless Steel Using Recurrence Plots, J. Appl. Electrochem., 2009, 39(5), p 637–645.

A.V. Bansod, A.P. Patil, A.P. Moon and N.N. Khobragade, Intergranular Corrosion Behavior of Low-Nickel and 304 Austenitic Stainless Steels, J. Mater. Eng. Perform., 2016, 25, p 3615–3626.

S.K. Pradhan, P. Bhuyan and S. Mandal, Individual and Synergistic Influences of Microstructural Features on Intergranular Corrosion Behavior in Extra-Low Carbon Type 304L Austenitic Stainless Steel, Corros. Sci., 2018, 139, p 319–332.

S. Jain, N.D. Budiansky, J.L. Hudson, J.R. Scully, Surface Spreading of Intergranular Corrosion on Stainless Steels. Corros. Sci., 2010, 52(3), p 873–885.

O.S. Savane, E. Khan, S. Freud, A. Murphy, K. Tesfargiogis and V. Murray, Persistent Pockets of Low Chlorine Residual in New York City's Drinking Water Distribution System: A Case Study, J. Am. Water Works Assoc., 2019, 111(10), p 40–50.

X. Hu, X. Renb, X. Chen, W. Han, F. Zou, A study on the corrosion of 316L stainless steel in the media of high-pressure carbamate condenser, In: Proceedings of the Asian-Pacific corrosion control conference, 8th ed. Bangkok, December 6–11; 1993, p 237–244.

X.J. Yang, M.H. Liu, Z.Y. Liu, C.W. Du and X.G. Li, Failure Analysis of a 304 Stainless Steel Heat Exchanger in Liquid Sulfur Recovery Units, Eng. Fail. Anal., 2020, 116, p 104729–104739.

A. Gruttadauria, S. Barella and R. Gerosa, An Overview of Austenitic Stainless-Steel Rock Anchors Damage in an Environment Rich with Chlorides, Eng. Fail. Anal., 2019, 100, p 88–102.

D.H. Du, K. Chen, H. Lu, L.F Zhang, X.Q Shi, X.L Xu, P. L. Andresen, Effects of Chloride and Oxygen on Stress Corrosion Cracking of Cold Worked 316/316L Austenitic Stainless Steel in High Temperature Water, Corros. Sci., 2016, 110, p 134–142.

S.A. Saadi, Y. Yi, P. Cho, C. Jang and P. Beeley, Passivity Breakdown of 316L Stainless Steel During Potentiodynamic Polarization in NaCl Solution, Corros. Sci., 2016, 111, p 720–727.

Y.D. Li, N. Xu, X.F. Wu, J.B. Shi, L.L. Zhang, M. Zhao and Q.S. Zang, Failure Analysis of the 304 Stainless Steel Tube in a Gas Analyzer, Eng. Fail. Anal., 2012, 20, p 35–42.

R. Nishimura, I. Musalam and M. Yasuaki, The Effect of sensitizing Temperature on Stress Corrosion Cracking of Type 316 Austenitic Stainless Steel in Hydrochloric Acid Solution, Corros. Sci., 2002, 44(6), p 1343–1360.

A.Y. Kina, V.M.D. Souza, S.S.M. Tavares, J.M. Pardal and J.A.D. Souza, Microstructure and intergranular Corrosion Resistance Evaluation of AISI 304 Steel for High Temperature Service, Mater. Charact., 2008, 59(5), p 651–655.

X.F. Yu and S.H. Chen, A Simulation of Cr Depletion In Austenitic Stainless Steel With Cellular Automaton, Comput. Mater. Sci., 2009, 45, p 899–904.

Q.R. Xiong, J.D. Robson, L.T. Chang, J.W. Fellowes and M.C. Smith, Numerical Simulation of Grain Boundary Carbides Evolution in 316H Stainless Steel, J. Nucl. Mater., 2018, 508, p 299–309.

Specification for Seamless and Welded Ferritic/Austenitic Stainless Steel Tubing for General Service, American Society for Testing and Materials, ASTM A789(2020).

D.E. Arthur, A. Jonathan, P.O. Ameh, C. Anya, A Review on the Assessment of Polymeric Materials Used as Corrosion Inhibitor of Metals and Alloys, Int. J. Ind. Chem. 2013, 4(1), Article 2.

C.R. Ascolese and D.I. Bain, Take Advantage of Effective Cooling Water Treatment Programs, Chem. Eng. Prog., 1998, 94(3), p 49–54.

Acknowledgments

This work was financially supported by National Key Research and Development Program of China (2019YFB2005002).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

He, H., Tian, W., Li, J. et al. Failure Analysis and Finite Element Simulation on Service Conditions of SUS304 Stainless Steel. J. of Materi Eng and Perform 30, 5987–5999 (2021). https://doi.org/10.1007/s11665-021-05744-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05744-x