Abstract

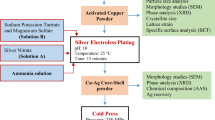

In this study, compact materials were fabricated by selective laser melting (SLM) method using copper-silver core-shell particles obtained by electroless coating method. The effect of SLM parameters such as laser power, scanning speed and hatch spacing on the important properties such as microstructure, density and electrical conductivity of compacts produced from core-shell particles was investigated. This study significantly contributes to the fact that the parameters used in the fabrication of copper-silver-based materials with the SLM method directly affect the properties of the compacts. The results showed that the silver shell thickness obtained on the core of copper powders by electroless plating method varied between 1 and 3 μm and was distributed homogeneously. It was also found that the highest apparent density value among all samples was obtained above about 99% from the sample where 100 W power, 250 mm/s scanning speed and 45% hatch spacing values were used. In addition the highest electrical conductivity value was obtained for these conditions.

Similar content being viewed by others

References

S.Y. Chang, J.H. Lin, S.J. Lin and T.Z. Kattamis, Processing Copper and Silver Matrix Composites by Electroless Plating and Hot Pressing, Metall. Mater. Trans. A, 1999, 30(4), p 1119–1136. https://doi.org/10.1007/s11661-999-0164-z

Y. Liu, Y. Yu and X. Zhao, The Influence of the Ratio of Graphite to Silver-Coated Copper Powders on the Electromagnetic and Mechanical Properties of Single-Layer Coated Composites, J. Text. Inst., 2020 https://doi.org/10.1080/00405000.2020.1839218

X.G. Cao and H.Y. Zhang, Preparation of Silver-Coated Copper Powder and Its Oxidation Resistance Research, Powder Technol., 2012, 226, p 53–56. https://doi.org/10.1016/j.powtec.2012.04.012

H.T.T. Hai, J.G.G. Ahn, D.J.J. Kim, J.R.R. Lee, H.S.S. Chung and C.O.O. Kim, Developing Process for Coating Copper Particles with Silver by Electroless Plating Method, Surf. Coatings Technol., 2006, 201(6), p 3788–3792. https://doi.org/10.1016/j.surfcoat.2006.03.025

A.K. Rudolphi, C. Bjorkman, T. Imrell, and S. Jacobson, “Conduction through Corrosion Films on Silver Plated Copper in Power Contacts,” Electrical Contacts-1995. Proceedings of the Forty-First IEEE Holm Conference on Electrical Contacts, IEEE, 1995, p 124–134, https://doi.org/10.1109/HOLM.1995.482865.

D.M. Felicia, R. Rochiem, and S.M. Laia, “The Effect of Silver (Ag) Addition to Mechanical and Electrical Properties of Copper Alloy (Cu) Casting Product.” AIP Conference Proceedings, 2018, p 020075, https://doi.org/10.1063/1.5030297.

O. Güler, Ü. Alver and T. Varol, Fabrication and Characterization of Novel Layered Materials Produced by Electroless Plating and Hot Pressing, J. Alloys Compd., 2020, 835, p 155278. https://doi.org/10.1016/j.jallcom.2020.155278

O. Güler, T. Varol, Ü. Alver and A. Çanakçı, The Effect of Flake-like Morphology on the Coating Properties of Silver Coated Copper Particles Fabricated by Electroless Plating, J. Alloys Compd., 2019, 782, p 679–688. https://doi.org/10.1016/j.jallcom.2018.12.229

O. Güler, T. Varol, Ü. Alver and A. Canakci, Effect of Al2O3 Content and Milling Time on the Properties of Silver Coated Cu Matrix Composites Fabricated by Electroless Plating and Hot Pressing, Mater. Today Commun., 2020, 24, p 101153. https://doi.org/10.1016/j.mtcomm.2020.101153

A.I. Titkov, O.A. Logutenko, A.M. Vorobyov, EYu. Gerasimov, I.K. Shundrina, N.V. Bulina and N.Z. Lyakhov, Synthesis of ˜10 Nm Size Cu/Ag Core-Shell Nanoparticles Stabilized by an Ethoxylated Carboxylic Acid for Conductive Ink, Colloids Surf. A Physicochem. Eng. Asp., 2019, 577, p 500–508. https://doi.org/10.1016/j.colsurfa.2019.06.008

X. Yu, J. Li, T. Shi, C. Cheng, G. Liao, J. Fan, T. Li and Z. Tang, A Green Approach of Synthesizing of Cu-Ag Core-Shell Nanoparticles and Their Sintering Behavior for Printed Electronics, J. Alloys Compd., 2017, 724, p 365–372. https://doi.org/10.1016/j.jallcom.2017.07.045

S. Tan, X. Zu, G. Yi and X. Liu, Synthesis of Highly Environmental Stable Copper-Silver Core–Shell Nanoparticles for Direct Writing Flexible Electronics, J. Mater. Sci. Mater. Electron., 2017, 28(21), p 15899–15906. https://doi.org/10.1007/s10854-017-7485-2

X.M. Zhang, Z.Z. Zhang and F.X. Zhao, Deposition of Silver Films on Copper Nanopowders by Three-Times Electroless Plating, J. Mater. Sci. Mater. Electron., 2016, 27(12), p 12485–12489. https://doi.org/10.1007/s10854-016-5577-z

L. Yang, R. Mertens, M. Ferrucci, C. Yan, Y. Shi and S. Yang, Continuous Graded Gyroid Cellular Structures Fabricated by Selective Laser Melting: Design, Manufacturing and Mechanical Properties, Mater. Des., 2019, 162, p 394–404. https://doi.org/10.1016/j.matdes.2018.12.007

D.S.J. Al-Saedi, S.H. Masood, M. Faizan-Ur-Rab, A. Alomarah and P. Ponnusamy, Mechanical Properties and Energy Absorption Capability of Functionally Graded F2BCC Lattice Fabricated by SLM, Mater. Des., 2018, 144, p 32–44. https://doi.org/10.1016/j.matdes.2018.01.059

I. Yadroitsev, A. Gusarov, I. Yadroitsava and I. Smurov, Single Track Formation in Selective Laser Melting of Metal Powders, J. Mater. Process. Technol., 2010, 210(12), p 1624–1631. https://doi.org/10.1016/j.jmatprotec.2010.05.010

S. Bose, D. Ke, H. Sahasrabudhe and A. Bandyopadhyay, Additive Manufacturing of Biomaterials, Prog. Mater. Sci., 2018, 93, p 45–111. https://doi.org/10.1016/j.pmatsci.2017.08.003

M. Sadowski, L. Ladani, W. Brindley and J. Romano, Optimizing Quality of Additively Manufactured Inconel 718 Using Powder Bed Laser Melting Process, Addit. Manuf., 2016, 11, p 60–70.

J. Robinson, M. Stanford and A. Arjunan, Correlation between Selective Laser Melting Parameters, Pore Defects and Tensile Properties of 99.9% Silver, Mater. Today Commun., 2020, 25, p 101550. https://doi.org/10.1016/j.mtcomm.2020.101550

G. Kaya, F. Yildiz and İ Hacisalihoğlu, Characterization of the Structural and Tribological Properties of Medical Ti6Al4V Alloy Produced in Different Production Parameters Using Selective Laser Melting, 3D Print, Addit. Manuf., 2019, 6(5), p 253–261. https://doi.org/10.1089/3dp.2019.0017

H. Attar, S. Ehtemam-Haghighi, D. Kent, I.V. Okulov, H. Wendrock, M. Bonisch, A.S. Volegov, M. Calin, J. Eckert and M.S. Dargusch, Nanoindentation and Wear Properties of Ti and Ti-TiB Composite Materials Produced by Selective Laser Melting, Mater. Sci. Eng. A, 2017, 688, p 20–26. https://doi.org/10.1016/j.msea.2017.01.096

S.D. Jadhav, S. Dadbakhsh, L. Goossens, J.-P. Kruth, J. Van Humbeeck and K. Vanmeensel, Influence of Selective Laser Melting Process Parameters on Texture Evolution in Pure Copper, J. Mater. Process. Technol., 2019, 270, p 47–58. https://doi.org/10.1016/j.jmatprotec.2019.02.022

E.O. Olakanmi, R.F. Cochrane and K.W. Dalgarno, A Review on Selective Laser Sintering/Melting (SLS/SLM) of Aluminium Alloy Powders: Processing, Microstructure, and Properties, Prog. Mater. Sci., 2015, 74, p 401–477. https://doi.org/10.1016/j.pmatsci.2015.03.002

W. Xiong, L. Hao, Y. Li, D. Tang, Q. Cui, Z. Feng and C. Yan, Effect of Selective Laser Melting Parameters on Morphology, Microstructure, Densification and Mechanical Properties of Supersaturated Silver Alloy, Mater. Des., 2019, 170, p 107697. https://doi.org/10.1016/j.matdes.2019.107697

J. Huang, X. Yan, C. Chang, Y. Xie, W. Ma, R. Huang, R. Zhao, S. Li, M. Liu and H. Liao, Pure Copper Components Fabricated by Cold Spray (CS) and Selective Laser Melting (SLM) Technology, Surf. Coatings Technol., 2020, 395, p 125936. https://doi.org/10.1016/j.surfcoat.2020.125936

Y. Zhang, B. Song, X. Zhao and Y. Shi, Microstructure and Properties of Ag/SnO2 Functional Material Manufactured by Selective Laser Melting, Nano Mater. Sci., 2019, 1(3), p 208–214.

H. Rieper, A. Gebhardt, and B. Stucker, Selective Laser Melting of the Eutectic Silver-Copper Alloy Ag 28 Wt% Cu. RTejournal-Forum für Rapid Technol., 2017.

A. Gebhardt, M. Fateri, J.S. Hötter, M. Knothe, F.M. Schmidt, and H. Rieper, Numerical and Experimental Investigation of Selective Laser Melting of Silver. Fraunhofer Direct Digit. Manuf. Conf. (DDMC), Berlin, 2012.

S. Scudino, C. Unterdörfer, K.G. Prashanth, H. Attar, N. Ellendt, V. Uhlenwinkel and J. Eckert, Additive Manufacturing of Cu-10Sn Bronze, Mater. Lett., 2015, 156, p 202–204.

H. Zhang, H. Zhu, T. Qi, Z. Hu and X. Zeng, Selective Laser Melting of High Strength Al–Cu–Mg Alloys: Processing, Microstructure and Mechanical Properties, Mater. Sci. Eng. A, 2016, 656, p 47–54. https://doi.org/10.1016/j.msea.2015.12.101

X. Xu, X. Luo, H. Zhuang, W. Li and B. Zhang, Electroless Silver Coating on Fine Copper Powder and Its Effects on Oxidation Resistance, Mater. Lett., 2003, 57(24–25), p 3987–3991. https://doi.org/10.1016/S0167-577X(03)00252-0

L. Thijs, F. Verhaeghe, T. Craeghs, J. Van Humbeeck and J.P. Kruth, A Study of the Microstructural Evolution during Selective Laser Melting of Ti-6Al-4V, Acta Mater., 2010, 58(9), p 3303–3312.

J.B. Tong, X. Lu, C.C. Liu, L.N. Wang and X.H. Qu, Fabrication of Micro-Fine Spherical High Nb Containing TiAl Alloy Powder Based on Reaction Synthesis and RF Plasma Spheroidization, Powder Technol., 2015, 283, p 9–15. https://doi.org/10.1016/j.powtec.2015.04.062

X. Zi, C. Chen, X. Wang, P. Wang, X. Zhang and K. Zhou, Spheroidisation of Tungsten Powder by Radio Frequency Plasma for Selective Laser Melting, Mater. Sci. Technol., 2018, 34(6), p 735–742. https://doi.org/10.1080/02670836.2017.1410955

S. Leuders, M. Thöne, A. Riemer, T. Niendorf, T. Tröster, H.A. Richard and H.J. Maier, On the Mechanical Behaviour of Titanium Alloy TiAl6V4 Manufactured by Selective Laser Melting: Fatigue Resistance and Crack Growth Performance, Int. J. Fatigue, 2013, 48, p 300–307. https://doi.org/10.1016/j.ijfatigue.2012.11.011

M.M. Parvez, T. Pan, Y. Chen, S. Karnati, J.W. Newkirk and F. Liau, High Cycle Fatigue Performance of LPBF 304L Stainless Steel at Nominal and Optimized Parameters, Materials, 2020, 13, p 1591. https://doi.org/10.3390/ma13071591

Acknowledgment

This study was financially supported by Scientific and Technological Research Council of Turkey (TÜBİTAK) through the Project no: 119M398. The authors would like to thank TÜBİTAK for its financial support in conducting this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical focus in the Journal of Materials Engineering and Performance on Additive Manufacturing. The issue was organized by Dr. William Frazier, Pilgrim Consulting, LLC; Mr. Rick Russell, NASA; Dr. Yan Lu, NIST; Dr. Brandon D. Ribic, America Makes; and Caroline Vail, NSWC Carderock.

Rights and permissions

About this article

Cite this article

Varol, T., Hacısalihoğlu, İ., Kaya, G. et al. The Effect of Selective Laser Melting Process on the Microstructure, Density, and Electrical Conductivity of Silver-Coated Copper Cores. J. of Materi Eng and Perform 30, 5216–5226 (2021). https://doi.org/10.1007/s11665-021-05712-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05712-5