Abstract

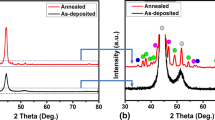

In the current study, oxidation and wear resistance of FeAl and (Fe,Cr)Al intermetallic compounds as well as (Fe,Cr)Al-5%vol Al2O3 and (Fe,Cr)Al-10%vol Al2O3 nanocomposites were investigated. Ball-milled powders were hot-pressed at 5.5 GPa and 1600 °C for 15 min in order to produce the bulk samples. The cyclic oxidation test was performed at 1100 °C for 100h. High-temperature wear tests were conducted at 400 °C with loads of 20 N in sliding speed and sliding distance of 0.1 m/s and 500 m, respectively. Furthermore, the nano-scratch tests were performed in single-direction as well as pass and return modes with a maximum load of 20 mN. Results showed that the (Fe,Cr)Al intermetallic compound had superior oxidation resistance with the lowest kp value at the same oxidation time. The improved oxidation performance of (Fe,Cr)Al intermetallic compound compared to (Fe,Cr)Al-Al2O3 composites can be due to the presence of more Al in (Fe,Cr)Al sample. According to the nano-scratch test, (Fe,Cr)Al-10%vol Al2O3 nanocomposite (with H/E ratio of 0.036) had the best wear resistance. On the other hand, nanocomposites containing 5% and 10% of Al2O3 had the lowest friction coefficient (≈ 0.6 and 0.3, respectively). The main wear mechanism for the FeAl compound was adhesive wear, while, delamination was the main mechanism for samples containing Al2O3 nanoparticles. Although the formation of Al2O3 reinforcement nanoparticles somewhat decreases the oxidation resistance, it also resulted in significant overall improvement in the wear behavior.

Similar content being viewed by others

References

M. Zamanzade, A. Barnoush and C. Motz, A Review on the Properties of Iron Aluminide Intermetallics, Crystals, 2016, 6(1), p 10.

D.E. Alman, J.A. Hawk, J.H. Tylczak, C.P. Doğan and R.D. Wilson, Wear of Iron-aluminide Intermetallic-Based Alloys and Composites by Hard Particles, Wear, 2001, 251(1–12), p 875–884.

J. Yang, P. La, W. Liu and Q. Xue, Tribological Properties of FeAl Intermetallics under Dry Sliding, Wear, 2004, 257(1–2), p 104–109.

J. Qiu, I. Baker, F.E. Kennedy, Y. Liu and P.R. Munroe, The Effects of Stoichiometry on the Dry Sliding Wear of FeAl, Intermetallics, 2013, 40, p 19–27.

A. Leyland and A. Matthews, On the Significance of the H/E Ratio in Wear Control: A Nanocomposite Coating Approach to Optimised Tribological Behaviour, Wear, 2000, 246(1–2), p 1–11.

B.D. Beake, V.M. Vishnyakov and A.J. Harris, Nano-Scratch Testing of (Ti, Fe) Nx Thin Films on Silicon, Surf. Coatings Technol., 2017, 309, p 671–679.

H.J. Grabke, Oxidation of NiAl and FeAl, Intermetallics, 1999, 7(10), p 1153–1158.

A. Velon and I. Olefjord, Oxidation Behavior of Ni3Al and Fe3Al: II. Early Stage of Oxide Growth, Oxid. Met., 2001, 56(56), p 425–452.

J. Engkvist, U. Bexell, M. Grehk and M. Olsson, High temperature oxidation of FeCrAl-Alloys-Influence of Al-Concentration on Oxide Layer Characteristics, Mater. Corros., 2009, 60(11), p 876–881.

E. Airiskallio, E. Nurmi, M.H. Heinonen, I.J. Väyrynen, K. Kokko, M. Ropo, M.P.J. Punkkinen, H. Pitkänen, M. Alatalo and J. Kollár, High Temperature Oxidation of Fe-Al and Fe-Cr-Al Alloys: The Role of Cr as a Chemically Active Element, Corros. Sci., 2010, 52(10), p 3394–3404.

B. Pietrzyk, S. Miszczak, Ł Kaczmarek and M. Klich, Low Friction Nanocomposite Aluminum oxide/MoS2 Coatings Prepared by Sol-Gel Method, Ceram. Int., 2018, 44(7), p 8534–8539.

Z. Nasiri, M. Mashhadi and A. Abdollahi, Effect of Short Carbon Fiber Addition on Pressureless Densification and Mechanical Properties of ZrB2–SiC–Csf Nanocomposite, Int. J. Refract. Met. Hard Mater., 2015, 51, p 216–223.

A. Fathy, A. Wagih and A. Abu-Oqail, Effect of ZrO2 Content on Properties of Cu-ZrO2 Nanocomposites Synthesized by Optimized High Energy Ball Milling, Ceram. Int., 2019, 45(2), p 2319–2329.

J. Huang, H. Xie, L. Luo, X. Zan, D. Liu and Y. Wu, Preparation and Properties of FeAl/Al2O3 Composite Tritium Permeation Barrier Coating on Surface of 316L Stainless Steel, Surf. Coatings Technol., 2020, 383, p 125282.

F. Sourani, M.H. Enayati and A.H.W. Ngan, On the in Situ Synthesis of (Fe, Cr) Al and (Fe, Cr) Al–Al2O3 Nanostructured Materials, Mater. Res. Express, 2019, 6(8), p 0850c9.

I.A. Alhafez, A. Brodyanski, M. Kopnarski and H.M. Urbassek, Influence of Tip Geometry on Nanoscratching, Tribol. Lett., 2017, 65(1), p 1–13.

F. Sourani, M.H. Enayati, X. Zhou, S. Wang and A.H.W. Ngan, Nanoindentation Behavior of Nanostructured Bulk (Fe, Cr) Al and (Fe, Cr) Al-Al2O3 Nanocomposites, J. Alloys Compd., 2019, 792, p 348–356.

T.F. An, H.R. Guan, X.F. Sun and Z.Q. Hu, Effect of the Θ–α-Al2O3 Transformation in Scales on the Oxidation Behavior of a Nickel-Base Superalloy with an Aluminide Diffusion Coating, Oxid. Met., 2000, 54(3–4), p 301–316.

C.H. Xu, W. Gao and H. Gong, Oxidation Behaviour of FeAl Intermetallics The Effects of Y And/or Zr on Isothermal Oxidation Kinetics, Intermetallics, 2000, 8(7), p 769–779.

F.S. Sayyedan and M.H. Enayati, Evaluating Oxidation Behavior of Amorphous Aluminum Phosphate Coating, Appl. Surf. Sci., 2018, 455, p 821–830.

X. Lu, X.B. He, B. Zhang, X.H. Qu, L. Zhang, Z.X. Guo and J.J. Tian, High-Temperature Oxidation Behavior of TiAl-Based Alloys Fabricated by Spark Plasma Sintering, J. Alloys Compd., 2009, 478(1–2), p 220–225.

W. Haitao, W. Yuqing, Y. Huashun, and M.G.W. Zhifu, Effects of Composite Scale on High Temperature Oxidation Resistance of Fe-Cr-Ni Heat Resistant Alloy, Res. Dev., 2009, 6, p 109–114.

H. Pourmohammad, A. Bahrami, A. Eslami, and M. Taghipour, Failure Investigation on a Radiant Tube in an Ethylene Cracking Unit, Eng. Fail. Anal., 2019, 104, p 216–226.

M. Taghipour, A. Eslami, M. Salehi and A. Bahrami, An Investigation on Anti-Coking Behavior of Gas Phase Aluminide Coatings Applied on a High Performance Micro Alloyed (HP-MA) Steel, Elsevier, Surf. Coatings Technol., 2020, p 125607.

F. Sourani, M.H. Enayati, F. Ashrafizadeh, F.S. Sayyedan and P.K. Chu, Enhancing Surface Properties of (Fe, Cr) Al–Al2O3 Nanocomposite by Oxygen Ion Implantation, J. Alloys Compd., 2021, 853, p 156892.

W.S. Barakat, A. Wagih, O.A. Elkady, A. Abu-Oqail, A. Fathy and A. El-Nikhaily, Effect of Al2O3 Nanoparticles Content and Compaction Temperature on Properties of Al–Al2O3 Coated Cu Nanocomposites, Compos. Part B Eng., 2019, 175, p 107140.

G.P. Ram, S. Karthikeyan, P.E. Nicholas, and A.S. Sofia, Dry Sliding Wear Behavior of Electroless NIP and NIP-Al2O3 Composite Coatings, Mater. Today Proc., 2021, 37, p 2001–2009.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sourani, F., Enayati, M.H. & Taghipour, M. High-Temperature Oxidation and Wear Behavior of (Fe,Cr)Al Intermetallic Compound and (Fe,Cr)Al-Al2O3 Nanocomposites. J. of Materi Eng and Perform 30, 3654–3669 (2021). https://doi.org/10.1007/s11665-021-05710-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05710-7