Abstract

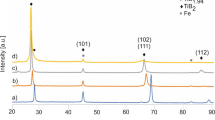

Co-based coating has been fabricated on Ti-6Al-4V (TC4) titanium alloy by laser cladding. The phase composition and microstructure of the coating were analyzed using metallurgical microscope (MM), scanning electron microscope (SEM), x-ray diffraction (XRD), energy-dispersive spectroscopy (EDS) and transmission electron microscopy (TEM), respectively. The microhardness, high temperature wear resistance and corrosion resistance of the coating were investigated by performance tests. The results show that the coating was mainly composed of CoTi, CoTi2 and Co0.5Cr1.5Ti crystalline phases and an amorphous phase. The microhardness of the coating was twice that of the titanium alloy substrate. The value of friction and wear coefficient of the coating was lower and more stable, and the wear mass loss decreased by 52% as compared with the substrate in the high-temperature friction and wear test. The oxidative wear mechanism in the condition of high temperature friction and wear was studied. Moreover, the coating exhibited better corrosion resistance than the substrate in both NaCl and H2SO4 electrolyte solutions.

Similar content being viewed by others

References

Z. Wu, Y. Xing, P. Huang, and L. Liu, Tribological Properties of Dimple-Textured Titanium Alloys Under Dry Sliding Contact, Surf. Coat. Technol., 2017, 309, p 21–28.

H. Li, M. Ramezani, and Z.W. Chen, Dry Sliding Wear Performance and Behaviour of Powder Bed Fusion Processed Ti-6Al-4V Alloy, Wear, 2019, 203, p 440–441.

T. Furuta, Chapter 4-Automobile Applications of Titanium, Titanium for Consumer Applications. F. Froes, M. Qian, M. Niinomi Ed., Elsevier, Amsterdam, 2019, p 77–90

H. Meifeng, L. Lei, W. Yating, T. Zhixin, and H. Wenbin, Corrosion Properties of Surface-Modified AZ91D Magnesium Alloy, Corros. Sci., 2008, 50, p 3267–3273.

F.M. El-Hossary, N.Z. Negm, S.M. Khalil, and M. Raaif, Surface Modification of Titanium by Radio Frequency Plasma Nitriding, Thin Solid Films, 2006, 497, p 196–202.

N. Tsuji, S. Tanaka, and T. Takasugi, Evaluation of Surface-Modified Ti-6Al-4V Alloy by Combination of Plasma-Carburizing and Deep-Rolling, Mater. Sci. Eng. A., 2008, 488, p 139–145.

H.-J. Song, S.-H. Park, S.-H. Jeong, and Y.-J. Park, Surface Characteristics and Bioactivity of Oxide Films Formed by Anodic Spark Oxidation on Titanium in Different Electrolytes, J. Mater. Process. Technol., 2009, 209, p 864–870.

M.Y.P. Costa, M.L.R. Venditti, M.O.H. Cioffi, H.J.C. Voorwald, V.A. Guimarães, and R. Ruas, Fatigue Behavior of PVD Coated Ti-6Al-4V Alloy, Int. J. Fatigue., 2011, 33, p 759–765.

Y. Zhu, W. Wang, X. Jia, T. Akasaka, S. Liao, and F. Watari, Deposition of TiC Film on Titanium for Abrasion Resistant Implant Material by Ion-Enhanced Triode Plasma CVD, Appl. Sur. Sci., 2012, 262, p 156–158.

S. Krischok, C. Blank, M. Engel, R. Gutt, G. Ecke, J. Schawohl, L. Spieß, F. Schrempel, G. Hildebrand, and K. Liefeith, Influence of Ion Implantation on Titanium Surfaces for Medical Applications, Surf. Sci., 2007, 601, p 3856–3860.

N. Tamanna, R. Crouch, and S. Naher, Progress in Numerical Simulation of the Laser Cladding Process, Opt. Laser. Eng., 2019, 122, p 151–163.

I.N. Maliutina, H. Si-Mohand, R. Piolet, F. Missemer, A.I. Popelyukh, N.S. Belousova, and P. Bertrand, Laser Cladding of γ-TiAl Intermetallic Alloy on Titanium Alloy Substrates, Metall. Mater. Trans. A, 2016, 47, p 378–387.

Y. Xue and H.M. Wang, Microstructure and Dry Sliding Wear Resistance of CoTi Intermetallic Alloy, Intermetallics, 2009, 17, p 89–97.

F. Weng, H. Yu, J. Liu, C. Chen, J. Dai, and Z. Zhao, Microstructure and Wear Property of The Ti5Si3/TiC Reinforced Co-based Coatings Fabricated by Laser Cladding on Ti-6Al-4V, Opt. Laser. Technol., 2017, 92, p 156–162.

W. Li, P. Xu, Y. Wang, Y. Zou, H. Gong, and F. Lu, Laser Synthesis and Microstructure of Micro- and Nano-Structured WC Reinforced Co-based Cladding Layers on Titanium Alloy, J. Alloys Compd., 2018, 749, p 10–22.

O.S. Fatoba, O.S. Adesina, and A.P.I. Popoola, Evaluation of Microstructure, Microhardness, and Electrochemical Properties of Laser-Deposited Ti-Co Coatings on Ti-6Al-4V Alloy, Int. J. Adv. Manuf. Technol., 2018, 97, p 2341–2350.

Y. Wang, X.-B. Liu, Y.-F. Liu, Y.-S. Luo, and Y. Meng, Microstructure and Tribological Performance of Ni60-Based Composite Coatings on Ti6Al4V Alloy with Different Ti3SiC2 Ceramic Additions by Laser Cladding, Ceram. Int., 2020, 46, p 28996–29010.

C.-M. Lin, W.-Y. Kai, C.-Y. Su, and K.-H. Key, Empirical Alloys-by-Design Theory Calculations to the Microstructure Evolution Mechanical Properties of Mo-Doped Laser Cladding NiAl Composite Coatings on Medium Carbon Steel Substrates, J. Alloys Compd., 2017, 702, p 679–686.

C. Wang, Y. Gao, R. Wang, D. Wei, M. Cai, and Y. Fu, Microstructure of Laser-Clad Ni60 Cladding Layers Added with Different Amounts of Rare-Earth Oxides on 6063 Al Alloys, J. Alloys Compd., 2018, 740, p 1099–1107.

T. Yu, Y. Zhao, J. Sun, Y. Chen, and W. Qu, Process Parameters Optimization and Mechanical Properties of Forming Parts by Direct Laser Fabrication of YCF101 Alloy, J. Mater. Process. Technol., 2018, 262, p 75–84.

D. Song, W. Sun, J.-Y. Jiang, H. Ma, J.-C. Zhang, and Z.-J. Cheng, Corrosion Behavior of Cr Micro-Alloyed Corrosion-Resistant Rebar in Neutral Cl−-Containing Environment, J. Iron. Steel. Res. Int., 2016, 23, p 608–617.

A. Takeuchi and A. Inoue, Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element, Mater. Trans., 2005, 46, p 2817–2829.

R. Franz and C. Mitterer, Vanadium Containing Self-Adaptive Low-Friction Hard Coatings for High-Temperature Applications: A review, Surf. Coat. Technol., 2013, 228, p 1–13.

H. Hofmann, G. Frommeyer, and C. Derder, Creep Mechanisms in Particle Strengthened α-Titanium–Ti2Co Alloys, Mater. Sci. Eng. A., 1998, 245, p 127–134.

Y. Xue and H.M. Wang, Microstructure and Wear Properties of Laser Clad TiCo/Ti2Co Intermetallic Coatings on Titanium Alloy, Appl. Surf. Sci., 2005, 243, p 278–286.

Y. Xue and H.M. Wang, Microstructure and Properties of Ti-Co-Si Ternary Intermetallic Alloys, J. Alloys Compd., 2008, 464, p 138–145.

M. Ebrahimian, M.H. Enayati, F. Karimzadeh, Y. Min, and D.-E. Kim, Microstructure and Mechanical Properties of Hot-Pressed Ti-Co-Si Compounds Reinforced by Intermetallic Phases, Mater. Charact., 2021, 171, p 110816.

G. Jin, Z. Cai, Y. Guan, X. Cui, Z. Liu, Y. Li, M. Dong, and D. Zhang, High Temperature Wear Performance of Laser-Cladded FeNiCoAlCu High-Entropy Alloy Coating, Appl. Surf. Sci., 2018, 445, p 113–122.

P.F. Jiang, C.H. Zhang, S. Zhang, J.B. Zhang, J. Chen, and Y. Liu, Fabrication and Wear Behavior of TiC Reinforced FeCoCrAlCu-Based High Entropy Alloy Coatings by Laser Surface Alloying, Mater. Chem. Phys., 2020, 255, p 123571.

S. Yan, Y. Shi, J. Liu, and C. Ni, Effect of Laser Mode on Microstructure and Corrosion Resistance of 316L Stainless Steel Weld Joint, Opt. Laser. Technol., 2019, 113, p 428–436.

S. Wan, C.-H. Miao, R.-M. Wang, Z.-F. Zhang, and Z.-H. Dong, Enhanced Corrosion Resistance of Copper by Synergetic Effects of Silica and BTA Codoped in Polypyrrole Film, Prog. Org. Coat., 2019, 129, p 187–198.

T. Brylewski, A. Gil, A. Rakowska, S. Chevalier, A. Adamczyk, J. Dabek, A. Kruk, M. Stygar, and K. Przybylski, Improving the Physicochemical Properties of Fe-25Cr Ferritic Steel for SOFC Interconnects via Y-Implantation and Y2O3-Deposition, Oxid. Met., 2013, 80, p 83–111.

L.M. Zhang, S.D. Zhang, A.L. Ma, H.X. Hu, Y.G. Zheng, B.J. Yang, and J.Q. Wang, Thermally Induced Structure Evolution on the Corrosion Behavior of Al-Ni-Y Amorphous Alloys, Corros. Sci., 2018, 144, p 172–183.

L.M. Zhang, M.C. Yan, S.D. Zhang, L.Y. Zhu, A.J. Umoh, A.L. Ma, Y.G. Zheng, and J.Q. Wang, Significantly Enhanced Resistance to SRB Corrosion via Fe-Based Amorphous Coating Designed with High Dose Corrosion-Resistant and Antibacterial Elements, Corros. Sci., 2020, 164, p 108305.

Acknowledgments

This study was supported by the China Postdoctoral Science Foundation-General Program (Grant No. 2018M641822), National Natural Science Foundation of China (Grant No. 51905126) and National Natural Science Foundation of China (General Program, Grant No. 51875129).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shu, F., Wang, B., Zhang, S. et al. Microstructure, High-Temperature Wear Resistance, and Corrosion Resistance of Laser Cladded Co-Based Coating. J. of Materi Eng and Perform 30, 3370–3380 (2021). https://doi.org/10.1007/s11665-021-05704-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05704-5