Abstract

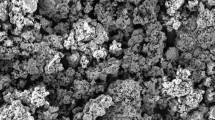

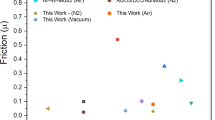

In this study, MoS2 solid lubricant films were supported with crystalline TiNi films for the first time in the literature to produce functional solid lubricant coatings. The structural, mechanical, and tribological properties of the produced coatings were investigated. The functional coatings were deposited on 52100 bearing steels by the Closed Field Unbalanced Magnetron Sputtering System (CFUBMS). SEM, XRD, EDS, and DSC analyses were used to obtain structural properties. A pin-on-disc Wear Test at atmospheric and high-temperature conditions was carried out to analyse the tribological behaviors of the coatings. The results showed that the TiNi/MoS2 functional coating had great tribological properties. S/Mo ratio and thickness and hardness values of the coatings directly affected tribological properties. The friction coefficients decreased as the S/Mo ratio of the coatings approached 1.5. Tribological properties generally increased as the hardness and thickness of the coatings increased. CoF values lower than 0.1 were obtained at atmospheric and high-temperature wear tests.

Similar content being viewed by others

References

H. Cho and S. Miyazaki, TiNi Multilayer Thin Films, Thin Film Shape Memory Alloys: Fundamentals and Device Applications, 2009.

P. Chen and J.M. Ting, Characteristics of TiNi Alloy Thin Films, Thin Solid Films, 2001, 398(399), p 597–601.

D. Li, Exploration of TiNi Shape Memory Alloy for Potential Application in a New Area: Tribological Engineering, Smart Mater. Struct., 2000, 9(1), p 717–726.

C. Zhang and Z.N. Farhat, Sliding Wear of Superelastic TiNi Alloy, Wear, 2009, 267(1–4), p 394–400.

Y.N. Liang, S.Z. Li, Y.B. Jin, W. Jin and S. Li, Wear Behavior of a TiNi Alloy, Wear, 1996, 198(1–2), p 236–241. https://doi.org/10.1016/0043-1648(96)06989-X

D.Y. Li, Development of Novel Tribo Composites with TiNi Shape Memory Alloy Matrix, Wear, 2003, 255(1–6), p 617–628.

W. Ni, Y.-T. Cheng and D.S. Grummon, Wear Resistant Self-Healing Tribological surfaces By Using Hard Coatings on NiTi Shape Memory Alloys, Surf. Coatings Technol., 2006, 201(3–4), p 1053–1057. https://doi.org/10.1016/j.surfcoat.2006.01.067

W. Cai, X.L. Meng and L.C. Zhao, Recent Development of TiNi-Based Shape Memory Alloys, Curr. Opin. Solid State Mater. Sci., 2005, 9(6), p 296–302. https://doi.org/10.1016/j.cossms.2006.07.002

Y. Wang, R. Xu, S. Hu, F. Tu, and W. Jin, Research Combining Experiment and FEM Analysis on Sliding Wear Behaviors and Mechanisms of TiNi alloy, Wear, 2017.

R. Neupane and Z. Farhat, Wear and dent resistance of superelastic TiNi Alloy, Wear, 2013.

B. Vierneusel, T. Schneider, S. Tremmel, S. Wartzack and T. Gradt, Humidity Resistant mos2 Coatings Deposited by Unbalanced Magnetron Sputtering, Surf. Coatings Technol., 2013, 235, p 97–107.

H. Cicek and I. Efeoglu, Fatigue and Adhesion Properties of Martensite and Austenite Phases of TiNi Shape Memory Thin Films Deposited by Magnetron Sputtering, Surf. Coatings Technol., 2016, 308, p 174–181.

Z. Li, X. Cheng, and Q. Shangguan, Effects of Heat Treatment and ECAE Process on Transformation Behaviors of TiNi Shape Memory Alloy, Mater. Lett., 2005.

D.E. Gusev, K.S. Senkevich, and M.I. Knyazev, Effect of High-Temperature Treatment on the Structure and Properties of TiNi-Base Alloys, Met. Sci. Heat Treat. 2012.

I. Efeoglu, Ö. Baran, F. Yetim and S. Altıntaş, Tribological Characteristics of MoS2–Nb Solid Lubricant Film in Different Tribo-Test Conditions, Surf. Coatings Technol., 2008, 203(5), p 766–770. https://doi.org/10.1016/j.surfcoat.2008.08.048

S. Miyazaki, Y.Q. Fu, and W.M. Huang, Thin Film Shape Memory Alloys: Fundamentals and Device Applications, Thin Film Shape Memory Alloys: Fundamentals and Device Applications, 2009

H.J. Lee, H. Ni, D.T. Wu, and A.G. Ramirez, Grain Size Estimations from the Direct Measurement of Nucleation and Growth, Appl. Phys. Lett., 2005.

F. Bülbül, I. Efeoglu, and E. Arslan, The effect of Bias Voltage and Working Pressure on S/Mo Ratio at MoS 2-Ti composite films, Appl. Surf. Sci., 2007.

I. Lahouij, B. Vacher, J.M. Martin, and F. Dassenoy, IF-MoS2 Based Lubricants: Influence of Size, Shape and Crystal Structure, Wear, 2012.

Ö. Baran, Adhesion and Fatigue Resistance of Ta-Doped MoS2 Composite Coatings Deposited with pulsed-DC Magnetron Sputtering, J. Adhes. Sci. Technol., 2017.

Ö. Baran, F. Bidev, H. Çiçek, L. Kara, I. Efeoğlu, and T. Küçükömeroğlu, Investigation of the Friction and Wear Properties of Ti/TiB2/MoS2 Graded-Composite Coatings Deposited by CFUBMS Under Air and Vacuum Conditions, Surf. Coatings Technol., 2014.

A. Aubert, J.P. Nabot, J. Ernoult and P. Renaux, Preparation and Properties of MoSx Films Grown by D.C. Magnetron Sputtering, Surf. Coatings Technol., 1990, 41(1), p 127–134. https://doi.org/10.1016/0257-8972(90)90136-Z

C. Borgia, S. Olliges, M. Dietiker, G. Pigozzi, and R. Spolenak, A combinatorial study on the influence of cu addition, film thickness and heat treatment on phase composition, texture and mechanical properties of Ti-Ni shape memory alloy thin films, Thin Solid Films, 2010.

J.M. Martin, C. Grossiord, T. Le Mogne, and J. Igarashi, Transfer Films and Friction Under Boundary Lubrication, Wear, 2000

D. Bhaduri, R. Kumar, A.K. Jain, and A.K. Chattopadhyay, on Tribological Behaviour and Application of TiN and MoS2-Ti Composite Coating for Enhancing Performance of Monolayer CBN Grinding Wheel, Wear, 2010.

D.G. Teer, New Solid Lubricant Coatings, Wear, 2001, 251(1–12), p 1068–1074.

X. Zhang, R.G. Vitchev, W. Lauwerens, L. Stals, J. He, and J.P. Celis, Effect of Crystallographic Orientation on Fretting Wear Behaviour of MoSx Coatings in Dry and Humid Air, Thin Solid Films, 2001.

H.H. Chien, K.J. Ma, S.V.P. Vattikuti, C.H. Kuo, C.B. Huo, and C.L. Chao, Tribological Behaviour of MoS2/Au Coatings, Thin Solid Films, 2010.

X. Quan, M. Hu, X. Gao, Y. Fu, L. Weng, D. Wang, D. Jiang, and J. Sun, Friction and Wear Performance of Dual Lubrication Systems Combining WS2-MoS2 Composite Film and Low Volatility Oils Under Vacuum Condition, Tribol. Int., 2016.

H. Çiçek, Structural and Tribological Characterization of Amorphous and Crystalline Titanium-Nickel Coatings, J. Adhes. Sci. Technol., 2019.

T.F. Babuska, A.A. Pitenis, M.R. Jones, B.L. Nation, W.G. Sawyer, and N. Argibay, Temperature-Dependent Friction and Wear Behavior of PTFE and MoS2, Tribol. Lett., 2016.

X. Dangsheng, Lubrication Behavior of Ni-Cr-Based Alloys Containing MoS2 at High Temperature, Wear, 2001.

H. Cicek, O.C. Akar, and I. Efeoglu, Structure and Adhesion Properties of TiNi/MoS2 Coatings. Ceramics International, 2021, 47(10), p 14033–14040

Acknowledgment

This research was supported by the TÜBİTAK (Scientific and Technological Research Council of Turkey), Project Number of 117M149.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cicek, H., Akar, O.C. & Efeoglu, I. Tribological Properties of TiNi/MoS2 Functional Coatings. J. of Materi Eng and Perform 30, 3632–3641 (2021). https://doi.org/10.1007/s11665-021-05703-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05703-6