Abstract

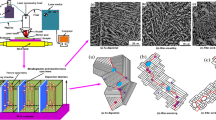

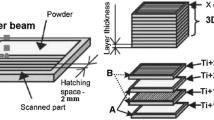

Intermetallics based on gamma titanium aluminide (γ-TiAl) alloys are potential lightweight materials that can be used for high-temperature components. However, poor room temperature ductility hinders their full potential for producing components using conventional manufacturing routes. This work is focused on the study of the microstructure and mechanical properties of ternary Ti-Al-Si alloy fabricated through laser in situ alloying by utilizing laser engineered net shaping (LENS) technology with subsequent heat treatment. The produced samples were analyzed using a scanning electron microscope (SEM) equipped with an energy-dispersed spectroscope (EDS) to investigate the composition and microstructure. Phase identification was investigated with x-ray diffraction (XRD) and electron backscattered diffraction (EBSD). Vickers hardness testing machine was utilized to determine the microhardness values, while the yield strength and tensile strength were calculated from the hardness results. Based on the results obtained, the microstructure of the heat-treated and as-produced ternary Ti-Al-Si alloy comprised mainly of α2-Ti3Al, γ-TiAl and ζ-Ti5Si3 phases. The SEM and EBSD results confirmed the phases formed, especially the fine lath structures of α2 in the colonies of α2/γ lamellae. The quantity of ζ-Ti5Si3 present in the LENS produced ternary alloy contributed majorly to the reported microhardness values. The sample heat-treated at 1150 °C/15 min/air-cooled (AC)/950 °C /6 h/furnace cooled (FC) (sample E1) had the lowest microhardness value of 624 Hv (6118 MPa or 6.12 GPa), with a corresponding tensile strength of 2325 MPa and yield strength of 1022 MPa. This was ascribed to the occurrence of more colonies of α2/γ lamellar in comparison with other samples.

Similar content being viewed by others

References

C. Hong, D. Gu, D. Dai, M. Alkhayat, W. Urban, P. Yuan, S. Cao, A. Gasser, A. Weisheit, I. Kelbassa, and M. Zhong, Laser Additive Manufacturing of Ultrafine TiC Particle Reinforced Inconel 625 Based Composite Parts: Tailored Microstructures and Enhanced Performance, Mater. Sci. Eng.: A., 2015, 635, p 118–128. https://doi.org/10.1016/j.msea.2015.03.043

M. Baumers, P. Dickens, C. Tuck, and R. Hague, The Cost of Additive Manufacturing: Machine Productivity, Economies of Scale and Technology-Push, Technol. Forecast. Soc. Chang., 2016, 102, p 193–201. https://doi.org/10.1016/j.techfore.2015.02.015

S.A. Raji, A.P.I. Popoola, S.L. Pityana, O.M. Popoola, F.O. Aramide, M. Tlotleng, and N.K.K. Arthur, Laser Based Additive Manufacturing Technology for Fabrication of Titanium Aluminide-Based Composites in Aerospace Component Applications, Environmental Impact of Aviation and Sustainable Solutions, IntechOpen, 2019. https://doi.org/10.5772/intechopen.85538.

X. Zhang, C. Li, M. Zheng, Z. Ye, X. Yang, and J. Gu, Anisotropic Tensile Behavior of Ti-47Al-2Cr-2Nb Alloy Fabricated by Direct Laser Deposition, Addit. Manuf., 2020 https://doi.org/10.1016/j.addma.2020.101087

M. Tlotleng, Microstructural Properties of Heat-Treated LENS In Situ Additively Manufactured Titanium Aluminide, J. Mater. Eng. Perform., 2019, 28(2), p 701–708. https://doi.org/10.1007/s11665-018-3789-5

B. Onuike, B. Heer, and A. Bandyopadhyay, Additive Manufacturing of Inconel 718—Copper Alloy Bimetallic Structure using Laser Engineered Net Shaping (LENS™), Addit. Manuf., 2018, 21, p 133–140. https://doi.org/10.1016/j.addma.2018.02.007

Y. Hu, F. Ning, H. Wang, W. Cong, and B. Zhao, Laser Engineered Net Shaping of Quasi-Continuous Network Microstructural TiB Reinforced Titanium Matrix Bulk Composites: Microstructure and Wear Performance, Opt. Laser Technol., 2018, 99, p 174–183. https://doi.org/10.1016/j.optlastec.2017.08.032

M. Tlotleng and S. Pityana, Effects of Al and Heat Treatment on the Microstructure and Hardness of Ti-Al Synthesized via In Situ Melting using LENS, Metals., 2019, 9(6), p 623. https://doi.org/10.3390/met9060623

A.R.C. Sharman, J.I. Hughes, and K. Ridgway, Characterisation of Titanium Aluminide Components Manufactured by Laser Metal Deposition, Intermetallics, 2018, 93, p 89–92. https://doi.org/10.1016/j.intermet.2017.11.013

Y. Wu, X. Cheng, S. Zhang, D. Liu, and H. Wang, Microstructure and Phase Evolution in γ-TiAl/Ti2AlNb Dual Alloy Fabricated by Direct Metal Deposition, Intermetallics, 2019, 106, p 26–35. https://doi.org/10.1016/j.intermet.2018.12.008

M. Tlotleng, B. Masina, and S.L. Pityana, Characteristics of laser In-situ alloyed titanium aluminides coatings, International Conference on Sustainable Materials Processing and Manufacturing, SMPM 2017, 23-25 January 2017, Kruger National Park, South Africa, Procedia Manufacturing. 7 (2017) 39-45. https://doi.org/10.1016/j.promfg.2016.12.013.

S.E. Hoosain, S. Pityana, C.S. Freemantle, and M. Tlotleng, Heat treatment of In situ Laser-Fabricated Titanium Aluminide, Metals., 2018, 8(9), p 655. https://doi.org/10.3390/met8090655

S.A. Raji, A.P.I. Popoola, S.L. Pityana, and O.M. Popoola, Characteristic Effects of Alloying Elements on β Solidifying Titanium Aluminides: A Review, Heliyon., 2020, 6(7), p e04463. https://doi.org/10.1016/j.heliyon.2020.e04463

R.M. Imayev, V.M. Imayev, M. Oehring, and F. Appel, Alloy Design Concepts for Refined Gamma Titanium Aluminide Based Alloys, Intermetallics, 2007, 15(4), p 451–460. https://doi.org/10.1016/j.intermet.2006.05.003

L.E. Murr, S.M. Gaytan, A. Ceylan, E. Martinez, J.L. Martinez, D.H. Hernandez, B.I. Machado, D.A. Ramirez, F. Medina, S. Collins, and R.B. Wicker, Characterization of Titanium Aluminide Alloy Components Fabricated by Additive Manufacturing using Electron Beam Melting, Acta Mater., 2010, 58(5), p 1887–1894. https://doi.org/10.1016/j.actamat.2009.11.032

E. Schwaighofer, B. Rashkova, H. Clemens, A. Stark, and S. Mayer, Effect of Carbon Addition on Solidification Behavior, Phase Evolution and Creep Properties of an Intermetallic β-Stabilized γ-TiAl Based Alloy, Intermetallics, 2014, 46, p 173–184. https://doi.org/10.1016/j.intermet.2013.11.011

J. Liu, M. Dahmen, V. Ventzke, N. Kashaev, and R. Poprawe, The Effect of Heat Treatment on Crack Control and Grain Refinement in Laser Beam Welded Β-Solidifying TiAl-Based Alloy, Intermetallics, 2013, 40, p 65–70. https://doi.org/10.1016/j.intermet.2013.04.007

B.K. Singh, V.A. Kumar, R.K. Gupta, and A.K. Kanjarla, Evolution of Microstructure in Niobium Rich (α2 + γ) Based Titanium Aluminide Alloy During Hot Compression, Mater. Sci. Eng., A, 2019, 754, p 708–718. https://doi.org/10.1016/j.msea.2019.03.111

P. Erdely, P. Staron, E. Maawad, N. Schell, H. Clemens, and S. Mayer, Lattice and Phase Strain Evolution During Tensile Loading of an Intermetallic, Multi-Phase γ-TiAl Based Alloy, Acta Mater., 2018, 158, p 193–205. https://doi.org/10.1016/j.actamat.2018.07.062

M. Li, X. Wu, Y. Yang, Q. Wei, C. Yan, C. Cai, J. Liu, W. Li, and Y. Shi, TiAl/RGO (Reduced Graphene Oxide) Bulk Composites with Refined Microstructure and Enhanced Nanohardness Fabricated by Selective Laser Melting (SLM), Mater. Charact., 2018, 143, p 197–205. https://doi.org/10.1016/j.matchar.2018.05.040

M. Seifi, A.A. Salem, D.P. Satko, U. Ackelid, S.L. Semiatin, and J.J. Lewandowski, Effects of HIP on Microstructural Heterogeneity, Defect Distribution and Mechanical Properties of Additively Manufactured EBM Ti-48Al-2Cr-2Nb, J. Alloy. Compd., 2017, 729, p 1118–1135. https://doi.org/10.1016/j.jallcom.2017.09.163

A. Seidel, S. Saha, T. Maiwald, J. Moritz, S. Polenz, A. Marquardt, J. Kaspar, T. Finaske, E. Lopez, F. Brueckner, and C. Leyens, Intrinsic Heat Treatment within Additive Manufacturing of Gamma Titanium Aluminide Space Hardware, JOM., 2019, 71(4), p 1513–1519. https://doi.org/10.1007/s11837-019-03382-2

T. Klein, B. Rashkova, D. Holec, H. Clemens, and S. Mayer, Silicon Distribution and Silicide Precipitation During Annealing in an Advanced Multi-Phase γ-TiAl Based Alloy, Acta Mater., 2016, 110, p 236–245. https://doi.org/10.1016/j.actamat.2016.03.050

H.Z. Niu, Y.Y. Chen, S.L. Xiao, and L.J. Xu, Microstructure Evolution and Mechanical Properties of a novel Beta γ-TiAl Alloy, Intermetallics, 2012, 31, p 225–231. https://doi.org/10.1016/j.intermet.2012.07.012

H. Clemens, W. Wallgram, S. Kremmer, V. Güther, A. Otto, and A. Bartels, Design of Novel β-Solidifying TiAl Alloys with Adjustable β/B2-Phase Fraction and Excellent Hot-Workability, Adv. Eng. Mater., 2008, 10(8), p 707–713. https://doi.org/10.1002/adem.200800164

J.H. Lee, H.K. Park, J.H. Kim, J.H. Jang, S.K. Hong, and I.H. Oh, Constitutive Behavior and Microstructural Evolution in Ti-Al-Si Ternary Alloys Processed by Mechanical Milling and Spark Plasma Sintering, J. Market. Res., 2020, 9, p 2247–2258. https://doi.org/10.1016/j.jmrt.2019.12.056

F.S. Sun and F.S. Froes, Precipitation of Ti5Si3 Phase in TiAl Alloys, Mater. Sci. Eng., A, 2002, 328(1–2), p 113–121. https://doi.org/10.1016/S0921-5093(01)01678-1

A. Knaislová, P. Novák, J. Kopeček, and F. Průša, Properties Comparison of Ti-Al-Si Alloys Produced by Various Metallurgy Methods, Materials., 2019, 12(19), p 3084. https://doi.org/10.3390/ma12193084

A. Knaislová, J. Linhart, P. Novák, F. Průša, J. Kopeček, F. Laufek, and D. Vojtěch, Preparation of TiAl15Si15 Intermetallic Alloy by Mechanical Alloying and the Spark Plasma Sintering Method, Powder Metall., 2019, 62(1), p 54–60. https://doi.org/10.1080/00325899.2019.1569812

A. Knaislová, P. Novák, M. Cabibbo, F. Průša, C. Paoletti, L. Jaworska, and D. Vojtěch, Combination of Reaction Synthesis and Spark Plasma Sintering in Production of Ti-Al-Si Alloys, J. Alloy. Compd., 2018, 752, p 317–326. https://doi.org/10.1016/j.jallcom.2018.04.187

A. Knaislová, P. Novák, S. Cygan, L. Jaworska, and M. Cabibbo, High-Pressure Spark Plasma Sintering (HP SPS): A Promising and Reliable Method for Preparing Ti-Al-Si Alloys, Materials., 2017, 10(5), p 465. https://doi.org/10.3390/ma10050465

A. Knaislová, P. Novák, F. Průša, M. Cabibbo, L. Jaworska, and D. Vojtěch, High-temperature Oxidation of Ti-Al-Si Alloys Prepared by Powder Metallurgy, J. Alloy. Compd., 2019, 810, p 151895. https://doi.org/10.1016/j.jallcom.2019.151895

J.S. Wu, P.A. Beaven, and R. Wagner, The Ti3(Al, Si) + Ti5(Si, Al)3 Eutectic Reaction in the Ti-Al-Si System, Scr. Metall. Mater., 1990, 24(1), p 207–212. https://doi.org/10.1016/0956-716X(90)90593-6

J.H. Lee, H.K. Park, J.H. Jang, S.K. Hong, and I.H. Oh, Amorphization/Crystallization Behaviors of Ti50Al45Si5 Multi-Component Powder Treated by Mechanical Alloying and Subsequent Heat Treatment, J. Alloy. Compd., 2019, 797, p 612–621. https://doi.org/10.1016/j.jallcom.2019.05.047

A. Knaislová, P. Novák, and F. Průša, Preparation of Ti-Al-Si Alloys by Powder Metallurgy, Manuf. Technol., 2016, 16, p 1274–1278. https://doi.org/10.21062/ujep/x.2016/a/1213-2489/MT/16/6/1274

X.W. Du, J.N. Wang, and J. Zhu, The Influence of Si Alloying on the Crept Microstructure and Property of a TiAl Alloy Prepared by Powder Metallurgy, Intermetallics, 2001, 9(9), p 745–753. https://doi.org/10.1016/S0966-9795(01)00041-3

H.R. Jiang, Z.L. Wang, X.R. Feng, Z.Q. Dong, L. Zhang, and L.I.U. Yong, Effects of Nb and Si on High Temperature Oxidation of TiAl, Trans. Nonferrous Met. Soc. China., 2008, 18(3), p 512–517. https://doi.org/10.1016/S1003-6326(08)60090-4

G. Baudana, S. Biamino, B. Klöden, A. Kirchner, T. Weißgärber, B. Kieback, M. Pavese, D. Ugues, P. Fino, and C. Badini, Electron Beam Melting of Ti-48Al-2Nb-0.7 Cr-03 Si: Feasibility Investigation, Intermetallics, 2016, 73, p 43–49. https://doi.org/10.1016/j.intermet.2016.03.001

T.T. Cheng, M.R. Willis, and I.P. Jones, Effects of Major Alloying Additions on the Microstructure and Mechanical Properties of γ-TiAl, Intermetallics, 1999, 7(1), p 89–99. https://doi.org/10.1016/S0966-9795(98)00016-8

M. Todai, T. Nakano, T. Liu, H.Y. Yasuda, K. Hagihara, K. Cho, M. Ueda, and M. Takeyama, Effect of Building Direction on the Microstructure and Tensile Properties of Ti-48Al-2Cr-2Nb Alloy Additively Manufactured by Electron Beam Melting, Addit. Manuf., 2017, 13, p 61–70. https://doi.org/10.1016/j.addma.2016.11.001

C. Kenel, G. Dasargyri, T. Bauer, A. Colella, A.B. Spierings, C. Leinenbach, and K. Wegener, Selective Laser Melting of an Oxide Dispersion Strengthened (ODS) γ-TiAl Alloy Towards Production of complex Structures, Mater. Des., 2017, 134, p 81–90. https://doi.org/10.1016/j.matdes.2017.08.034

F. Zhang, M. Yang, A.T. Clare, X. Lin, H. Tan, and Y. Chen, Microstructure and Mechanical Properties of Ti-2Al Alloyed with Mo Formed in Laser Additive Manufacture, J. Alloy. Compd., 2017, 727, p 821–831. https://doi.org/10.1016/j.jallcom.2017.07.324

J.R. Cahoon, W.H. Broughton, and A.R. Kutzak, The Determination of Yield Strength from Hardness Measurements, Metall. Trans., 1971, 2(7), p 1979–1983. https://doi.org/10.1007/BF02913433

E.J. Pavlina and C.J. Van Tyne, Correlation of Yield Strength and Tensile Strength with Hardness for Steels, J. Mater. Eng. Perform., 2008, 17(6), p 888–893. https://doi.org/10.1007/s11665-008-9225-5

H. Chen and L.X. Cai, Theoretical Conversions of Different Hardness and Tensile Strength for Ductile Materials Based on Stress-Strain Curves, Metall. and Mater. Trans. A., 2018, 49(4), p 1090–1101. https://doi.org/10.1007/s11661-018-4468-8

B. Lin, W. Chen, Y. Yang, F. Wu, and Z. Li, Anisotropy of Microstructure and Tensile Properties of Ti-48Al-2Cr-2Nb Fabricated by Electron Beam Melting, J. Alloys Compd., 2020 https://doi.org/10.1016/j.jallcom.2020.154684

M. Simonelli, D.G. McCartney, P. Barriobero-Vila, N.T. Aboulkhair, Y.Y. Tse, A. Clare, and R. Hague, The Influence of Iron in Minimizing the Microstructural Anisotropy of Ti-6Al-4V Produced by Laser Powder-Bed Fusion, Metall. Mater. Trans. A., 2020 https://doi.org/10.1007/s11661-020-05692-6

M.N. Mathabathe, S. Govender, A.S. Bolokang, R.J. Mostert, and C.W. Siyasiya, Phase Transformation and Microstructural Control of the α-Solidifying γ-Ti-45Al-2Nb-0.7 Cr-0.3 Si Intermetallic Alloy, J. Alloys Compd., 2018, 757, p 8–15. https://doi.org/10.1016/j.jallcom.2018.05.051

P. Gao and Z. Wang, Tailored Microstructure and Enhanced Comprehensive Mechanical Properties of Selective Laser Melted Ti-40Al-9V-0.5 Y Alloy after Aging Treatment, Mater. Sci. Eng.: A., 2020, 780, p 139183. https://doi.org/10.1016/j.msea.2020.139183

L. Song, L. Wang, M. Oehring, X. Hu, F. Appel, U. Lorenz, F. Pyczak, and T. Zhang, Evidence for Deformation Twinning of the D019-α2 Phase in a High Nb Containing TiAl Alloy, Intermetallics, 2019, 109, p 91–96. https://doi.org/10.1016/j.intermet.2019.03.014

L. Song, L. Wang, T. Zhang, J. Lin, and F. Pyczak, Microstructure and phase transformations of ωo-Ti4Al3Nb based alloys after quenching and subsequent aging at intermediate temperatures, J. Alloy. Compd., 2020, 821, p 153387. https://doi.org/10.1016/j.jallcom.2019.153387

J.K. Kim, J.H. Kim, J.Y. Kim, S.H. Park, S.W. Kim, M.H. Oh, and S.E. Kim, Producing Fine Fully Lamellar Microstructure for Cast γ-TiAl without Hot Working, Intermetallics, 2020, 120, p 106728. https://doi.org/10.1016/j.intermet.2020.106728

M.J. Blackburn, Some Aspects of Phase Transformations in Titanium Alloys, Science, Technology, and Application of Titanium. R.I. Jaffee Ed., Oxford Pergamon Press Ltd: Boeing Scientific Research Labs, Seattle, USA, 1970, p 633–643. https://doi.org/10.1016/B978-0-08-006564-9.50071-3

X. Xu, J. Lin, J. Guo, X. Wang, and X. Yu, Microstructure and Properties of Friction Welding Joint of Ti-45Al-85Nb-0.2W-0.2B-0.02Y Alloy, Intermetallics, 2019, 112, p 106540. https://doi.org/10.1016/j.intermet.2019.106540

M. Oehring, A. Stark, J.D.H. Paul, T. Lippmann, and F. Pyczak, Microstructural Refinement of Boron-Containing β-Solidifying γ-Titanium Aluminide Alloys through Heat Treatments in the β Phase Field, Intermetallics, 2013, 32, p 12–20. https://doi.org/10.1016/j.intermet.2012.08.010

Acknowledgments

The authors would like to acknowledge the financial support (scholarship grant) from the African Laser Centre-National Laser Centre; Council of Scientific and Industrial Research (ALC-NLC; CSIR), Project Number LHIP500 Task ALC S100. The authors also acknowledge Mr Nana Kwamina Kum Arthur and Mr Paul Lekoadi both of CSIR for their assistance while carrying out the experiment.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflicts of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Raji, S.A., Popoola, A.P.I., Pityana, S.L. et al. Microstructure and Mechanical Properties of Heat-Treated Ti-Al-Si Alloy Produced via Laser In Situ Alloying. J. of Materi Eng and Perform 30, 3321–3332 (2021). https://doi.org/10.1007/s11665-021-05681-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05681-9