Abstract

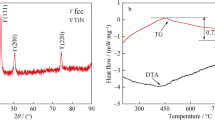

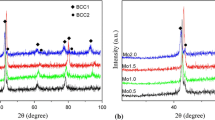

The directional array TiN-reinforced AlCoCrCuNiTi high-entropy alloy (HEA) coating was designed and the correlative coating was successfully synthesized by magnetic-field-assisted laser cladding on Ti-6Al-4V (TC4) alloy. The effect of the directional array TiN on the phase structure, microstructure, microhardness and wear resistance of HEA coating were investigated methodically. As a result, the HEA coatings are mainly composed of body-centered-cubic solid solution phase, (Ni, Co)Ti2 inter metallic compound and TiN ceramic phase. With 1 T magnetic induction intensity assisted laser cladding, the microstructure of in-situ TiN displays a "cross" shape of the directional array. And the coating shows excellent wear resistance with an average microhardness of 760 HV. The worn surface morphologies of HEA coatings show that the wear mechanism is adhesive wear regardless of whether a magnetic field is added. This work can provide a novel and effective method to synthesize directional array microstructures to improve the performance of HEA coating, which will promote the further application of directional array microstructures in advanced manufacturing fields.

Similar content being viewed by others

References

J. Su, D. Raabe and Z. Li, Hierarchical Microstructure Design to Tune the Mechanical Behavior of an Interstitial TRIP-TWIP High-Entropy Alloy, Acta Mater., 2019, 163, p 40–54.

G. Jin, Z.B. Cai, Y. Guan, X.F. Cui, Z. Liu, Y. Li and M.L. Dong, High Temperature Wear Performance of Laser-Cladded FeNiCoAlCu High-Entropy Alloy Coating, Appl. Surf. Sci., 2018, 445, p 113–122.

Z. Sun, X.P. Tan, M. Descoins, D. Mangelinck, S.B. Tor and C.S. Lim, Revealing Hot Tearing Mechanism for an Additively Manufactured High-Entropy Alloy Via Selective Laser Melting, Scripta Mater., 2019, 168, p 129–133.

C.C. Tung, J.W. Yeh, T.T. Shun, S.K. Chen, Y.S. Huang and H.C. Chen, On the Elemental Effect of AlCoCrCuFeNi High-Entropy Alloy System, Mater. Lett., 2007, 61(1), p 1–5.

N.D. Stepanov, N.Y. Yurchenko, S.V. Zherebtsov, M.A. Tikhonovsky and G.A. Salishchev, Aging Behavior of the HfNbTaTiZr High Entropy Alloy, Mater. Lett., 2018, 211, p 87–90.

Z. Tong, X. Ren, J. Jiao, W. Zhou, Y. Ren, Y. Ye, E.A. Larson and J. Gu, Laser Additive Manufacturing of FeCrCoMnNi High-Entropy Alloy: Effect of Heat Treatment on Microstructure, Residual Stress and Mechanical Property, J. Alloys Compd., 2019, 785, p 1144–1159.

Q. Lin, J. Liu, X. An, H. Wang, Y. Zhang and X. Liao, Cryogenic-Deformation-Induced Phase Transformation in an FeCoCrNi High-Entropy Alloy, Mater. Res. Lett., 2018, 6(4), p 236–243.

X.D. Xu, P. Liu, Z. Tang, A. Hirata, S.X. Song, T.G. Nieh, P.K. Liaw, C.T. Liu and M.W. Chen, Transmission Electron Microscopy Characterization of Dislocation Structure in a Face-Centered Cubic High-Entropy Alloy Al0.1CoCrFeNi, Acta Mater., 2018, 144, p 107–115.

J. Liu, X. Guo, Q. Lin, Z. He, X. An, L. Li, P.K. Liaw, X. Liao, L. Yu, J. Lin and L. Xie, Excellent Ductility and Serration Feature of Metastable CoCrFeNi High-Entropy Alloy at Extremely Low Temperatures, Sci. China Mater., 2019, 62(6), p 853–863.

X. Qiu, Microstructure, Hardness and Corrosion Resistance of Al2CoCrCuFeNiTix High-Entropy Alloy Coatings Prepared by Rapid Solidification, J. Alloys Compd., 2018, 735, p 359–364.

M.H. Esfahani, A.Z. Hanzaki, H.R. Abedi, H.S. Kim and D. Yim, The Enhancement of Transformation Induced Plasticity Effect Through Preferentially Oriented Substructure Development in a High Entropy Alloy, Intermetallics, 2019, 109, p 145–156.

Y.K. Kim, Y.A. Joo, H.S. Kim and K.A. Lee, High Temperature Oxidation Behavior of Cr-Mn-Fe-Co-Ni High Entropy Alloy, Intermetallics, 2018, 98, p 45–53.

F. Müller, B. Gorr, H.J. Christ, H. Chen, A. Kauffmann and M. Heilmaier, Effect of Microalloying with Silicon on High Temperature Oxidation Resistance of Novel Refractory High-Entropy Alloy Ta-Mo-Cr-Ti-Al, Mater. High Temp., 2018, 35(1–3), p 168–176.

H. Luo, Z. Li, A.M. Mingers and D. Raabe, Corrosion Behavior of an Equiatomic CoCrFeMnNi High-Entropy Alloy Compared with 304 Stainless Steel in Sulfuric Acid Solution, Corros. Sci., 2018, 15, p 131–139.

R.B. Nair, H.S. Arora, S. Mukherjee, S. Singh, H. Singh and H.S. Grewal, Exceptionally High Cavitation Erosion and Corrosion Resistance of a High Entropy Alloy, Ultrason. Sonochem., 2018, 41, p 252–260.

Y.S. Kim, H.J. Park, S.C. Mun, E. Jumaev, S.H. Hong, G. Song, J.T. Kim, Y.K. Park, K.S. Kim, S.I. Jeong and Y.H. Kwon, Investigation of Structure and Mechanical Properties of TiZrHfNiCuCo High Entropy Alloy Thin Films Synthesized by Magnetron Sputtering, J. Alloys Compd., 2019, 797, p 834–841.

H. Kim, S. Nam, A. Roh, M. Son, M.H. Ham, J.H. Kim and H. Choi, Mechanical and Electrical Properties of NbMoTaW Refractory High-Entropy Alloy Thin Films, Int. J. Refract. Met. H., 2019, 80, p 286–291.

J. Lu, B. Wang, X. Qiu, Z. Peng and M. Ma, Microstructure Evolution and Properties of CrCuFexNiTi High-Entropy Alloy Coating by Plasma Cladding on Q235, Surf. Coat. Tech., 2017, 328, p 313–318.

Z.H. Wang, H. Wang, D.Y. He, L. Cui, J.M. Jiang, Z. Zhou and Q.Y. Zhao, Microstructure Characterization of CoCrCuFeNiMn High Entropy Alloys by Plasma Cladding, Rare Metal Mat. Eng., 2015, 44(3), p 644–648.

A. Aliyu, M.Y. Rekha and C. Srivastava, Microstructure-electrochemical Property Correlation in Electrodeposited CuFeNiCoCr High-Entropy Alloy-Graphene Oxide Composite Coatings, Philos. Mag., 2019, 99(6), p 718–735.

S. Yin, W. Li, B. Song, X. Yan, M. Kuang, Y. Xu, K. Wen and R. Lupoi, Deposition of FeCoNiCrMn High Entropy Alloy (HEA) Coating Via Cold Spraying, J. Mater. Sci. Technol., 2019, 35(6), p 1003–1007.

K.C. Cheng, J.H. Chen, S. Stadler and S.H. Chen, Properties of Atomized AlCoCrFeNi High-Entropy Alloy Powders and Their Phase-adjustable Coatings Prepared Via Plasma Spray Process, Appl. Surf. Sci., 2019, 478, p 478–486.

S. Zhang, C.L. Wu, C.H. Zhang, M. Guan and J.Z. Tan, Laser Surface Alloying of FeCoCrAlNi High-Entropy Alloy on 304 Stainless Steel to Enhance Corrosion and Cavitation Erosion Resistance, Opt. Laser Technol., 2016, 84, p 23–31.

Z.B. Cai, X.F. Cui, Z. Liu, Y. Li, M.L. Dong and G. Jin, Microstructure and Wear Resistance of Laser Cladded Ni-Cr-Co-Ti-V High-Entropy Alloy Coating After Laser Remelting Processing, Opt. Laser Technol., 2018, 99, p 276–281.

R. Li, P. Niu, T. Yuan, P. Cao, C. Chen and K. Zhou, Selective Laser Melting of an Equiatomic CoCrFeMnNi High-Entropy Alloy: Processability, Non-Equilibrium Microstructure and Mechanical Property, J. Alloys Compd., 2018, 746, p 125–134.

G. Zhang, H. Liu, X. Tian, P. Chen, H. Yang and J. Hao, Microstructure and Properties of AlCoCrFeNiSi High-Entropy Alloy Coating on AISI 304 Stainless Steel by Laser Cladding, J. Mater. Eng. Perform., 2020, 29(1), p 278–288.

H. Torres, T. Vuchkov, M.R. Ripoll and B. Prakash, Tribological Behaviour of MoS2-Based Self-Lubricating Laser Cladding for Use in High Temperature Applications, Tribol. Int., 2018, 126, p 153–165.

Y. Feng, K. Feng, C. Yao, Z. Li and J. Sun, Microstructure and Properties of In-Situ Synthesized (Ti3Al + TiB)/Ti Composites by Laser Cladding, Mater. Design., 2018, 157, p 258–272.

Y. Guo, X. Shang and Q. Liu, Microstructure and Properties of In-Situ TiN Reinforced Laser Cladding CoCr2FeNiTix High-Entropy Alloy Composite Coatings, Surf. Coat. Tech., 2018, 344, p 353–358.

G. Ma, S. Yan, D. Wu, Q. Miao, M. Liu and F. Niu, Microstructure Evolution and Mechanical Properties of Ultrasonic Assisted Laser Clad Yttria Stabilized Zirconia Coating, Ceram. Int., 2017, 43(13), p 9622–9629.

N. Zhang, W. Liu, D. Deng, Z. Tang, X. Liu, Z. Yan and H. Zhang, Effect of Electric-Magnetic Compound Field on the Pore Distribution in Laser Cladding Process, Opt. Laser Technol., 2018, 108, p 247–254.

J. Yang, Z. Xiao, F. Yang, H. Chen, X. Wang and S. Zhou, Microstructure and Magnetic Properties of NiCrMoAl/WC Coatings by Laser Cladding: Effect of WC Metallurgical Behaviors, Surf. Coat. Tech., 2018, 350, p 110–118.

L.L. Zhai, C.Y. Ban and J.W. Zhang, Microstructure, Microhardness and Corrosion Resistance of NiCrBSi Coatings Under Electromagnetic Field Auxiliary Laser Cladding, Surf. Coat. Tech., 2019, 358, p 531–538.

Q.M. Liu, Y. Zhang, Y.L. Song, F.P. Qi and Q.J. Zhai, Influence of Ultrasonic Vibration on Mechanical Properties and Microstructure of 1Cr18Ni9Ti Stainless Steel, Mater. Design., 2007, 28(6), p 1949–1952.

P.Z. Si, Y. Yang, L.L. Yao, H.D. Qian, H.L. Ge, J. Park and C.J. Choi, Magnetic-Field-Enhanced Reactive Synthesis of MnBi from Mn Nanoparticles, J. Magn. Magn. Mater., 2019, 476, p 243–247.

R. Xu, L. Huang, J. Zhang, D. Li, J. Liu, J. Liu and G. Tang, Nanostructured SnSe Integrated with Se Quantum Dots with Ultrahigh Power Factor and Thermoelectric Performance from Magnetic Field-Assisted Hydrothermal Synthesis, J. Mater. Chem. A., 2019, 7(26), p 15757–15765.

Q. Zhang, H. Xu, X.H. Tan, X.L. Hou, S.W. Wu, G.S. Tan and L.Y. Yu, The Effects of Phase Constitution on Magnetic and Mechanical Properties of FeCoNi·(CuAl)x (x = 0-1.2) High-Entropy Alloys, J. Alloy Compd., 2017, 693, p 1061–1067.

Y. Li, X. Cui, G. Jin, Z. Cai, N. Tan, B. Lu and J. Liu, Influence of Magnetic Field on Microstructure and Properties of TiC/Cobalt-Based Composite Plasma Cladding Coating, Surf. Coat. Tech., 2017, 325, p 555–564.

A. Takeuchi and A. Inoue, Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element, Mater. Trans., 2005, 46(12), p 2817–2829.

J.X. Xue, G.J. Zhang, L.P. Guo, H.B. Zhang, X.G. Wang, J. Zou, S.M. Peng and X.G. Long, Improved Radiation Damage Tolerance of Titanium Nitride Ceramics by Introduction of Vacancy Defects, J. Eur. Ceram. Soc., 2014, 34(3), p 633–639.

U.K. Bhaskar, S. Bid, B. Satpati and S.K. Pradhan, Mechanosynthesis of Nanocrystalline Titanium Nitride and Its Microstructure Characterization, J. Alloys Compd., 2010, 493(1–2), p 192–196.

K.H.J. Buschow and R.B. Frank, Physics of Magnetism and Magnetic Materials, Kluwer Academic/Plenum Publishers, New York, 2003, p 7

Z. Ren, X. Li, H. Wang, K. Deng and Y. Zhuang, the Segregated Structure of MnBi in Bi–Mn Alloy Solidified under a High Magnetic Field, Mater. Lett., 2004, 58(27–28), p 3405–3409.

B. Li, L. Zhang, Y. Xu, Z. Liu, B. Qian and F. Xuan, Selective Laser Melting of CoCrFeNiMn High Entropy Alloy Powder Modified with Nano-TiN Particles for Additive Manufacturing and Strength Enhancement: Process, Particle Behavior and Effects, Powder Technol., 2020, 360, p 509–521.

H. Liu, J. Liu, P.J. Chen and H.F. Yang, Microstructure and High Temperature Wear Behaviour of In-situ TiC Reinforced AlCoCrFeNi-Based High-Entropy Alloy Composite Coatings Fabricated by Laser Cladding, Opt. Laser Technol., 2019, 118, p 140–150.

B. Li, B. Qian, Y. Xu, Z. Liu and F. Xuan, Fine-Structured CoCrFeNiMn High-Entropy Alloy Matrix Composite with 12 wt.% TiN Particle Reinforcements Via Selective Laser Melting Assisted Additive Manufacturing, Mater. Lett., 2019, 252, p 88–91.

Y.X. Guo, Q.B. Liu and X.J. Shang, In-situ TiN Reinforced CoCr2FeNiTi0.5 High-Entropy Alloy Composite Coating Fabricated by Laser Cladding, Rare Metals, 2020, 39(10), p 1190–1195

Acknowledgments

This work was financially supported by the National Natural Science Foundation of China (No. 51975137, 51775127), the Fundamental Research Funds for Province Universities (No. Hkdcx201903), Heilongjiang Provincial Natural Science Foundation of China (No. LH2020E120), the China Postdoctoral Science Foundation (No. 2018M641809).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liang, G., Jin, G., Cui, X. et al. Synthesis and Characterization of Directional Array TiN-Reinforced AlCoCrCuNiTi High-Entropy Alloy Coating by Magnetic-Field-Assisted Laser Cladding. J. of Materi Eng and Perform 30, 3568–3576 (2021). https://doi.org/10.1007/s11665-021-05680-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05680-w