Abstract

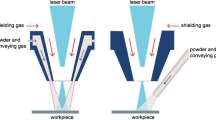

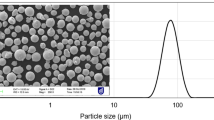

In this study, nanostructured WC-12Co powder was produced by ball milling and then agglomerating by spray drying. The produced nanostructured WC-12Co powder was used for laser cladding of AISI 321 stainless steel substrate. In order to evaluate the effect of argon shroud protection, the cladding process was performed with and without argon shroud protection. Microstructural and phase characterization showed that argon shroud protection can reduce the WC decarburization and the relative fraction of WC phase in clads reached up to 74%. In addition, microhardness and porosity percentage of the clads with argon shroud protection showed a significant improvement in comparison with the clads without argon shroud protection. The microhardness (to 2200 HV) and wear resistance increased and the porosity percentage decreased to less than 1%.

taken from the selected points

Similar content being viewed by others

References

A.S. Kurlov and A.I. Gusev, Tungsten Carbides: Structure, Properties and Application in Hardmetals, Springer Ser. Mater. Sci, 2013, 184, p 34–36.

S.A. Hewitt, T. Laoui and K.K. Kibble, Effect of Milling Temperature on the Synthesis and Consolidation of Nanocomposite WC–10Co Powders, Int. J. Refract. Met. Hard Mater., 2009, 27, p 66–73.

A. Mostajeran, R. Shoja-Razavi, M. Hadi, M. Erfanmanesh, M. Barekat and M. Savaghebi Firouzabadi, Evaluation of the mechanical properties of WC-FeAl Composite Coating Fabricated by Laser Cladding Method. Int. J. Refract. Met. Hard Mater. 88 (2020) 105199.

A. Alhaji, M. Shamanian, M. Salehi, S.M. Nahvi and M. Erfanmanesh, Electroless Nickel-Phosphorus Plating on WC–Co Powders Using HVOF Feedstock, Surf. Eng., 2019, 35, p 120–127.

A. S. Kurlov, Y. V. Blagoveshenskii, A. V. Samokhin, Y. V. Tsvetkov, Hard Alloys WC-Co (6 wt%) and WC-Co (10 wt%) Based on Nanocrystalline Powders, Dokl. Chem., 2011, 439, p 213–218.

D. Janisch, W. Lengauer, K. Rödiger, K. Dreyer and H. Van den Berg, Cobalt Capping: Why is Sintered Hardmetal Sometimes Covered with Binder?, Int. J. Refract. Met. Hard Mater., 2010, 28, p 466–471.

C. Pang, Z. Guo, J. Luo, T. Hou and J. Bing, Effect of Vanadium on Synthesis of WC Nanopowders by Thermal Processing of V-Doped Tungsten Precursor, Int. J. Refract. Met. Hard Mater., 2010, 28, p 394–398.

C.-J. Li and G.-J. Yang, Relationships Between Feedstock Structure, Particle Parameter, Coating Deposition, Microstructure and Properties for Thermally Sprayed Conventional and Nanostructured WC–Co, Int. J. Refract. Met. Hard Mater., 2013, 39, p 2–17.

A. Mateen, G. Saha, T. Khan and F. Khalid, Tribological Behaviour of HVOF Sprayed Near-Nanostructured and Microstructured WC-17 wt.% Co Coatings, Surf. Coat. Technol., 2011, 206, p 1077–1084.

W. Li, P. Xu, Y. Wang, Y. Zou, H. Gong and F. Lu, Laser Synthesis and Microstructure of Micro-and Nano-structured WC Reinforced Co-Based Cladding Layers on Titanium Alloy, J. Alloys Compd., 2018, 749, p 10–22.

Y. Zou, B. Ma, H. Cui, F. Lu and P. Xu, Microstructure, Wear, and Oxidation Resistance of Nanostructured Carbide-Strengthened Cobalt-Based Composite Coatings on Invar Alloys by Laser Cladding, Surf. Coat. Technol., 2020, 381, p 125188.

P. Chivavibul, M. Watanabe, S. Kuroda and K. Shinoda, Effects of Carbide Size and Co Content on the Microstructure and Mechanical Properties of HVOF-Sprayed WC–Co Coatings, Surf. Coat. Technol., 2007, 202, p 509–521.

J. Guilemany, S. Dosta and J. Miguel, The Enhancement of the Properties of WC-Co HVOF Coatings Through the Use of Nanostructured and Microstructured Feedstock Powders, Surf. Coat. Technol., 2006, 201, p 1180–1190.

A.K. Basak, J.-P. Celis, M. Vardavoulias and P. Matteazzi, Effect of Nanostructuring and Al Alloying on Friction and Wear Behaviour of Thermal Sprayed WC–Co Coatings, Surf. Coat. Technol., 2012, 206, p 3508–3516.

Y. Yang and H. Man, Microstructure Evolution of Laser Clad Layers of W-C–Co Alloy Powders, Surf. Coat. Technol., 2000, 132, p 130–136.

P.S. Babu, B. Basu and G. Sundararajan, Abrasive Wear Behavior of Detonation Sprayed WC–12Co Coatings: Influence of Decarburization and Abrasive Characteristics, Wear, 2010, 268, p 1387–1399.

M. Cadenas, R. Vijande, H. Montes and J. Sierra, Wear Behaviour of Laser Cladded and Plasma Sprayed WC-Co Coatings, Wear, 1997, 212, p 244–253.

B. Valsecchi, B. Previtali, M. Vedani and G. Vimercati, Fiber Laser Cladding with High Content of WC-Co Based Powder, Int. J. Mater. Form., 2010, 3, p 1127–1130.

M. Erfanmanesh, H. Abdollah-Pour, H. Mohammadian-Semnani and R. Shoja-Razavi, An Empirical-Statistical Model for Laser Cladding of WC-12Co Powder on AISI 321 Stainless Steel, Opt. Laser Technol., 2017, 97, p 180–186.

A.A.-A.P. Baumli and A. Al-Azzawi, Methods of Composite Coating: A Review, Mater. Sci. Eng., 2015, 40, p 26–32.

M. Erfanmanesh, S.R. Bakhshi, M. Khajelakzay and M. Salekbafghi, The Effect of Argon Shielding Gas at Plasma Spray Process on the Structure and Properties of MoSi2 Coating, Ceram. Int., 2014, 40, p 4529–4533.

C. Paul, H. Alemohammad, E. Toyserkani, A. Khajepour and S. Corbin, Cladding of WC–12 Co on Low Carbon Steel Using a Pulsed Nd: YAG Laser, Mater. Sci. Eng. A, 2007, 464, p 170–176.

S.A. Hewitt and K.A. Kibble, Effects of Ball Milling Time on the Synthesis and Consolidation of Nanostructured WC–Co Composites, Int. J. Refract. Met. Hard Mater., 2009, 27, p 937–948.

M.S. El-Eskandarany, A.A. Mahday, H. Ahmed and A. Amer, Synthesis and Characterizations of Ball-Milled Nanocrystalline WC and Nanocomposite WC–Co Powders and Subsequent Consolidations, J. Alloys Compds., 2000, 312, p 315–325.

J. He, M. Ice, E.J. Lavernia and S. Dallek, Synthesis of Nanostructured WC-12 pct Co Coating Using Mechanical Milling and High Velocity Oxygen Fuel Thermal Spraying, Metall. Mater. Trans. A, 2000, 31, p 541–553.

F. Zhang, C. Wang and M. Zhu, Nanostructured WC/Co Composite Powder Prepared by High Energy Ball Milling, Scr. Mater., 2003, 49, p 1123–1128.

J. Guilemany, J. De Paco, J. Miguel and J. Nutting, Characterization of the W2C Phase Formed During the High Velocity Oxygen Fuel Spraying of a WC+ 12 pct Co Powder, Metall. Mater. Trans. A, 1999, 30, p 1913–1921.

A. Dent, S. DePalo and S. Sampath, Examination of the Wear Properties of HVOF Sprayed Nanostructured and Conventional WC-Co Cermets with Different Binder Phase Contents, J. Therm. Spray Technol., 2002, 11, p 551–558.

B. Obadele, P. Olubambi and O. Johnson, Effects of TiC Addition on Properties of Laser Particle Deposited WC–Co–Cr and WC–Ni Coatings, Trans. Nonferrous Met. Soc. China, 2013, 23, p 3634–3642.

T. Qing, J. Wang, C. Wang, W. Lai, L. Jianyang, and G. Fanjun, CO3W3C Fishbone-Like Hard Phase-Reinforced Fe-Based Wear-Resistant Coating and Preparation Thereof, in Google Patents (2017)

M. Jafari, M. Enayati, M. Salehi, S. Nahvi and C. Park, Microstructural and Mechanical Characterizations of a Novel HVOF-Sprayed WC-Co Coating Deposited from Electroless Ni–P Coated WC-12Co Powders, Mater. Sci. Eng. A, 2013, 578, p 46–53.

S. Lay, C. Allibert, M. Christensen and G. Wahnström, Morphology of WC Grains in WC–Co alloys, Mater. Sci. Eng. A, 2008, 486, p 253–261.

M. Jafari, M. Enayati, M. Salehi, S. Nahvi and C. Park, Microstructural Evolution of Nanosized Tungsten Carbide During Heatup Stage of Sintering of Electroless Nickel-Coated Nanostructured WC–Co Powder, Ceram. Int., 2014, 40, p 11031–11039.

V. Kumar, Z.Z. Fang, S. Wright and M. Nowell, An Analysis of Grain Boundaries and Grain Growth in Cemented Tungsten Carbide Using Orientation Imaging Microscopy, Metall. Mater. Trans. A, 2006, 37, p 599–607.

X. Wang, Z.Z. Fang and H.Y. Sohn, Grain Growth During the Early Stage of Sintering of Nanosized WC–Co Powder, Int. J. Refract. Met. Hard Mater., 2008, 26, p 232–241.

S. Zafar and A.K. Sharma, Dry Sliding Wear Performance of Nanostructured WC–12Co Deposited Through Microwave Cladding, Tribol. Int., 2015, 91, p 14–22.

M. Erfanmanesh, R. Shoja-Razavi, H. Abdollah-Pour, H. Mohammadian-Semnani, M. Barekat and S.H. Hashemi, Friction and Wear Behavior of Laser Cladded WC-Co and Ni/WC-Co Deposits at High Temperature, Int. J. Refract. Met. Hard Mater., 2019, 81, p 137–148.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Habibi, A.H., Shoja Razavi, R., Borhani, G.H. et al. Effect of Argon Shroud Protection on the Laser Cladding of Nanostructured WC-12Co Powder. J. of Materi Eng and Perform 30, 3313–3320 (2021). https://doi.org/10.1007/s11665-021-05675-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05675-7