Abstract

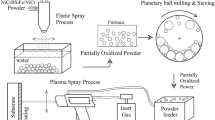

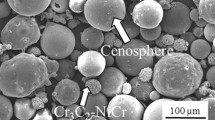

The composite coating was developed and investigated the solid particle erosion performance at elevated temperature by varying impact angles. Al2O3 erodent of grit size 50 µm was used in air-jet erosion tester to investigate the resistance to erosion at RT, 200, 400, 600, and 800 °C by varying 30, 45, 60, 75, and 90° impact angles. The composite coating was deposited on MDN321 steel by plasma spray process with feedstock of “30 weight percent of partially oxidized Al powder and 70 wt.% of NiCr alloy powder.” The composite coating was characterized by bond strength, porosity, micro-hardness, and density. Volumetric erosion loss concerning temperature and impact angle was studied using SEM, EDAX, and XRD analysis. Non-contact three-dimensional optical profilometer was used to quantify the volumetric erosion loss. MDN321 steel showed better erosion resistance than composite coating at all the temperatures. Due to the formation of stable oxides at 800 °C the erosion resistance of the coating was improved.

Similar content being viewed by others

References

S.B. Mishra, K. Chandra, S. Prakash, and B. Venkataraman, Erosion Performance of Coatings Produced by Shrouded Plasma Spray Process on a Co-Based Superalloy, Surf. Coat. Technol., 2006, 201, p 1477–1487

E. Bousser, L. Martinu, and J.E. Klemberg-Sapieha, Solid Particle Erosion Mechanisms of Protective Coatings for Aerospace Applications, Surf. Coat. Technol., 2014, 257, p 165–181

Y.Q. Xiao, L. Yang, Y.C. Zhou, Y.G. Wei, and N.G. Wang, Dominant Parameters Affecting the Reliability of TBCs on a Gas Turbine Blade during Erosion by a Particle-Laden Hot Gas Stream, Wear, 2017, 390–391(July), p 166–175

S.B. Mishra, K. Chandra, and S. Prakash, Erosion-Corrosion Performance of NiCrAlY Coating Produced by Plasma Spray Process in a Coal-Fired Thermal Power Plant, Surf. Coat. Technol., 2013, 216, p 23–34

J.B. Cheng, X.B. Liang, Y.X. Chen, Z.H. Wang, and B.S. Xu, High-Temperature Erosion Resistance of FeBSiNb Amorphous Coatings Deposited by Arc Spraying for Boiler Applications, J. Therm. Spray Technol., 2013, 66, p 820–827

H.S. Grewal, H. Singh, and A. Agrawal, Microstructural and Mechanical Characterization of Thermal Sprayed Nickel-Alumina Composite Coatings, Surf. Coat. Technol., 2013, 216, p 78–92

S. Matthews, B. James, and M. Hyland, High Temperature Erosion-Oxidation of Cr3C2-NiCr Thermal Spray Coatings under Simulated Turbine Conditions, Corros. Sci., 2013, 70, p 203–211

Y. Wang, Y. Yang, and M.F. Yan, Microstructures, Hardness and Erosion Behavior of Thermal Sprayed and Heat Treated NiAl Coatings with Different Ceria, Wear, 2007, 263, p 371–378

I.R.V. Geaman, M.A. Pop, and D.L. Motoc, “Tribological Properties of Thermal Spray Coatings,” European Scientific Journal, 2013, 3, p 154–159

P. Bagde, S.G. Sapate, R.K. Khatirkar, and N. Vashishtha, Friction and Abrasive Wear Behaviour of Al2O3-13TiO2 and Al2O3-13TiO2+Ni Graphite Coatings, Tribol. Int., 2018, 121, p 353–372

A. Richter, L.M. Berger, Y.J. Sohn, S. Conze, K. Sempf, and R. Vaßen, Impact of Al2O3-40 Wt.% TiO2 Feedstock Powder Characteristics on the Sprayability, Microstructure and Mechanical Properties of Plasma Sprayed Coatings, J. Eur. Ceram. Soc., 2019, 39(16), p 5391–5402

X. Yang, S. Dong, J. Zeng, X. Zhou, J. Jiang, L. Deng, and X. Cao, Sliding Wear Characteristics of Plasma-Sprayed Cr2O3 Coatings with Incorporation of Metals and Ceramics, Ceram. Int., 2019, 66, p 20243–20250

H.S. Nithin, V. Desai, and M.R. Ramesh, Elevated Temperature Solid Particle Erosion Performance of Plasma-Sprayed Co-Based Composite Coatings with Additions of Al2O3 and CeO2, J. Mater. Eng. Perform., 2017, 26, p 5251–5261

H. Long, T. Yefa, T. Hua, T. Yiqiang, and Z. Zhongwei, “Microstructure and Tribological Properties of WC-CeO2/Ni-Base Alloy Composite Coatings,” Rare Met. Mater. Eng., 2014, 43, p 823–829

C.D.K. Yang, J. Rong, J. Feng, Y. Zhuang, H. Zhao, L. Wang, J. Ni, S. Tao, and F. Shao, Excellent Wear Resistance of Plasma-Sprayed Amorphous Al2O3-Y3Al5O12 Ceramic Coating, Surf. Coat. Technol., 2017, 326, p 96–102

Y.H. Chae and S.S. Kim, Tribological Performance of Al2O3/NiCr Coating, KSME Int. J., 2002, 16(7), p 911–918

S.R. Medabalimi, M.R. Ramesh, and R. Kadoli, High-Temperature Wear and Frictional Behavior of Partially Oxidized Al with NiCr Composite Coating, Mater. Res. Express IOP Publi., 2019, 6(12), p 1–13

M. Akhtari Zavareh, A.A.D.M. Sarhan, B.B. Razak, and W.J. Basirun, The Tribological and Electrochemical Behavior of HVOF-Sprayed Cr3C2-NiCr Ceramic Coating on Carbon Steel, Ceram. Int., 2015, 41, p 5387–5396

J. Zhu, L. Ma, and R. Dwyer-Joyce, Friction and Wear Behaviours of Self-Lubricating Peek Composites for Articulating Pin Joints, Tribol. Int., 2019, 149, p 1–10

N.C. Reddy, B.S.A. Kumar, H.N. Reddappa, M.R. Ramesh, P.G. Koppad, and S. Kord, HVOF Sprayed Ni3Ti and Ni3Ti+(Cr3C2+20NiCr) Coatings: Microstructure, Microhardness and Oxidation Behaviour, J. Alloys Compd., 2018, 736, p 236–245

X. Shi, W. Zhai, M. Wang, Z. Xu, J. Yao, S. Song, and Y. Wang, Tribological Behaviors of NiAl Based Self-Lubricating Composites Containing Different Solid Lubricants at Elevated Temperatures, Wear, 2014, 310, p 1–11

H.S. Sidhu, B.S. Sidhu, and S. Prakash, Comparative Characteristic and Erosion Behavior of NiCr Coatings Deposited by Various High-Velocity Oxyfuel Spray Processes, J Mater. Eng. Perform., 2006, 15, p 699–704

J.J. Tian, S.W. Yao, X.T. Luo, C.X. Li, and C.J. Li, An Effective Approach for Creating Metallurgical Self-Bonding in Plasma-Spraying of NiCr-Mo Coating by Designing Shell-Core-Structured Powders, Acta Mater., 2016, 110, p 19–30

M. Mathapati, M.R. Ramesh, and M. Doddamani, High Temperature Erosion Behavior of Plasma Sprayed NiCrAlY/WC-Co/Cenosphere Coating, Surf. Coat. Technol., 2017, 325, p 98–106

B. Song, S. Dong, H. Liao, and C. Coddet, Microstructure and Wear Resistance of FeAl/Al2O3 intermetallic Composite Coating Prepared by Atmospheric Plasma Spraying, Surf. Coat. Technol., 2015, 268, p 24–29

V.H. Hidalgo, F.J.B. Varela, A.C. Menéndez, and S.P. Martínez, A Comparative Study of High-Temperature Erosion Wear of Plasma-Sprayed NiCrBSiFe and WC-NiCrBSiFe Coatings under Simulated Coal-Fired Boiler Conditions, Tribol. Int., 2001, 34, p 161–169

J.A. Hearley, J.A. Little, and A.J. Sturgeon, “The Erosion Behaviour of NiAl Intermetallic Coatings Produced by High Velocity Oxy-Fuel Thermal Spraying,” Wear, 1999, 233-235, p 328–333

N. Krishnamurthy, M.S. Murali, B. Venkataraman, and P.G. Mukunda, Characterization and Solid Particle Erosion Behavior of Plasma Sprayed Alumina and Calcia-Stabilized Zirconia Coatings on Al-6061 Substrate, Wear, 2012, 274–275, p 15–27

H. Zhang, X. Dong, and S. Chen, Solid Particle Erosion-Wear Behaviour of Cr3C2-NiCr Coating on Ni-Based Superalloy, Adv. Mech. Eng., 2017, 9(3), p 1–9

Acknowledgments

The authors would like to thank “Aum Techno Spray Pvt. Ltd Bangalore, India" for providing a research facility to prepare and develop a composite coating and to Mr. Sandesh Birla, IIT Bombay, Manufacturing Engineering, for his support to get the 3D profile images from Alicona focus variation microscopy. This research did not receive any financial support from any government or private sector.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Subba Rao, M., Ramesh, M.R. & Ravikiran, K. Solid Particle Erosion Behavior of Partially Oxidized Al with NiCr Composite Coating at Elevated Temperature. J. of Materi Eng and Perform 30, 3749–3760 (2021). https://doi.org/10.1007/s11665-021-05668-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05668-6