Abstract

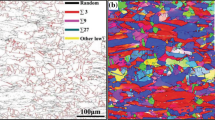

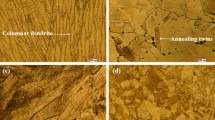

The electron backscatter electron diffraction (EBSD) technique was applied to study the microstructure evolution and properties of the annealed cold rolling C71500 cupronickel alloy tube. The fixed reduction ratio of C71500 alloy tube was 23.71%. After rolling with different thickness reduction, the change process of grain, the evolution of texture, the characteristic distribution of grain boundary and the mechanical properties of the alloy tube were discussed systematically. The texture of cold rolling tube was obviously different from the drawing and sheet textures, and only the textures of RZ{111<110> type and R-cube{001}<110> type could be observed after the two roller cold rolling process. After a certain amount of deformation, obvious accumulated orientation differences could be seen in the textures, which could create favourable conditions for the recrystallization nucleation. In the rolling process, the nonuniformity deformation of tube was caused by the inconsistency of stress state. With the increase reduction of tube wall, the tensile strength of the alloy increased from 405.13 to 574.65 MPa, the yield strength increased from 310.35 to 338.76 MPa, and the micro-Vickers hardness increased from 137.40 to 186.01.

Similar content being viewed by others

References

Y.L. Zhu, W. Zheng, Z. Song and F. Han, Development and Application of Nickel-copper Alloy in China, Hot Working Technol., 2019, 48(8), p 23–26.

X. Gao, H. Wu, M. Liu, Y. Zhang, F. Gao and H. Sun, Processing Map of C71500 Copper-Nickel Alloy and Application in Production Practice, J. Wuhan Univ. Technol. (Mater. Sci.), 2020, 35(06), p 1104–1115.

X. Gao, H. Wu, M. Liu, Y. Zhang and F. Gao, Corrosion Behavior of High Strength C71500 Cu-Ni Alloy Pipe in Simulated High Sulfide Polluted Seawater at Different Temperatures, Int. J. Electrochem. Sci., 2021, 16(2), p 150932.

X. Gao, H. Wu, D. Tang, D. Li, M. Liu and X. Zhou, Six Different Mathematical Models to Predict the Hot Deformation Behavior of C71500 Cupronickel Alloy, Rare Met. Mater. Eng., 2020, 49(12), p 4129–4141.

X. Gao, H. Wu, M. Liu, X. Zhou and Y. Zhang, Analysis of the Influence of Sulfur on the Hot Tensile Fracture of C71500 Cu-Ni Alloy, J. Mater. Eng. Perform., 2021, 30, p 312–319.

P. Lin, G. Palumbo, U. Erb and K.T. Aust, Influence of Grain Boundary Character Distribution on Sensitization and Intergranular Corrosion of Alloy 600, Scr. Metall. Mater., 1995, 33, p 1387–1392.

V. Randle, Mechanism of Twinning-Induced Grain Boundary Engineering in Low Stacking-Fault Energy Materials, Acta Mater., 1999, 47(15–16), p 4187–4196.

M. Shimada, H. Kokawa, Z.J. Wang, Y.S. Sato and I. Karibe, Optimization of Grain Boundary Character Distribution for Intergranular Corrosion Resistant 304 Stainless Steel by Twin-Induced Grain Boundary Engineering, Acta Mater., 2002, 50(9), p 2331–2341.

M. Michiuchi, H. Kokawa, Z.J. Wang, Y.S. Sato and K. Sakai, Twin-Induced Grain Boundary Engineering for 316 Austenitic Stainless Steel, Acta Mater., 2006, 54(19), p 5179–5184.

S.W. Wang, S.-H. Zhang, H.-W. Song and Y. Chen, Evolution of Microstructure of TP2 Copper Tube During Drawing Process, Chin. J. Nonferrous Met., 2019, 29(04), p 124–131.

S.-W. Wang, Y. Chen, H.-W. Song, A.A. El-Aty and S.-H. Zhang, Investigation of Texture Transformation Paths in Copper Tube During Floating Plug Drawing Process, Int. J. Mater. Form., 2020, 3, p 1–13.

D.H. Liu, Y.C. Su, C.P. Deng, Q.P. Hu and Z.Y. Pan, Microstructure and Properties of ACR Copper Tube During Three-Roll Planetary Milling Process, Chin. J. Nonferrous Met., 2006, 16(5), p 881–886.

Z. Wang, X. Zhang, Y. Deng and C. Ming, Twins and Texture of Super-Alloy IN690 Tube by Extrusion, Rare Met. Mater. Eng., 2014, 43(9), p 2252–2256.

J. Mei, X. Liu, Y. Jiang and X. Jian-xin, Evolution of Microstructure, Texture and Mechanical Properties of BFe10-1-1 Tube with Microstructure Along Axial Orientation During Cold-Rolling, Chin. J. Nonferrous Met., 2012, 9, p 2529–2538.

C. Xingpin, C. Dan, S. Hongfu and W. Lixia, Effects of Cold Rolling Reduction and Annealing Temperature on Microstructure and Texture Evolution of Cu-44%Ni Alloy, Rare Met. Mater. Eng., 2018, 047(007), p 1958–1964.

X. Gao, H.-B. Wu, M. Liu and Y.-X. Zhang, Effect of Annealing Time on Grain Boundary Characteristics of C71500 Cupronickel Alloy Tubes with Different Deformation, Mater. Charact., 2020, 169, p 110603.

J. Hou, Q.J. Peng, Z.P. Lu, T. Shoji, J.Q. Wang, E.H. Han and W. Ke, Effects of Cold Working Degrees on Grain Boundary Characters and Strain Concentration at Grain Boundaries in Alloy 600, Corros. Sci., 2011, 53(3), p 1137–1142.

D.A. Hughes and N. Hansen, Microstructural Evolution in Nickel During Rolling and Torsion, Met. Sci. J., 1991, 7(6), p 544–553.

R.D. Doherty, D.A. Hughes, F.J. Humphreys, J.J. Jonas, D.J. Jensen, M.E. Kassner, W.E. King, T.R. Mcnelley, H.J. Mcqueen and A.D. Rollett, Current Issues in Recrystallization: A Review, Mater. Sci. Eng. A Struct. Mater. Prop. Microstruct. Process., 1997, 238(2), p 219–274.

D.A. Hughes, N. Hansen and D.J. Bammann, Geometrically Necessary Boundaries, Incidental Dislocation Boundaries and Geometrically Necessary Dislocations, Scr. Mater, 2003, 48(2), p 147–153.

V.S. Ananthan, T. Leffers and N. Hansen, Cell and Band Structures in Cold Rolled Polycrystalline Copper, Mater. Sci. Technol., 1991, 7(12), p 1069–1075.

X. Gao, H. Wu, M. Liu, Y. Zhang and X. Zhou, Dynamic Recovery and Recrystallization Behaviors of C71500 Copper-Nickel Alloy Under Hot Deformation, J. Mater. Eng. Perform., 2020, 29(11), p 7678–7692.

P. Liu and L. Xiaotang, Copper and Copper Alloy Processing Manual, Chemical Industry Press, Beijing, 2008.

Z.-G. Wang, X.-Y. Feng, T.-S. Yang, Y.-H. Zhang and X.-P. Xiao, Effects of Precipitates and Texture on the Anisotropy of High-Strength Cu–Ni–Si Alloy Sheets, Chin. J. Eng., 2017, 39(06), p 867–874.

J. Zhou, L. Shen and X. Honglaing, Effect of Microstructure and Texture of Pure Copper Straight Tubes on Surface Defects Forming, Heat Treat. Met., 2018, 43(12), p 245–249.

Acknowledgment

This study was financially supported by Ministry of Industry and Information Technology of the People's Republic of China (TC170A2KN-8) and the National Natural Science Foundation of China (No. 51801149). The authors would like to take this opportunity to express their sincere appreciation to the funds.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, X., Wu, Hb., Liu, M. et al. Effect of Thickness Reduction on Microstructure and Properties of Rolled C71500 Cupronickel Alloy Tube. J. of Materi Eng and Perform 30, 3273–3283 (2021). https://doi.org/10.1007/s11665-021-05667-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05667-7