Abstract

In this present investigation, geopolymer specimens were prepared by fly ash powder and various concentrations of NaOH solution maintained at 10 molar (M), 12 molar (M) and 14 molar (M) along with Na2SiO3 solution followed by artificial curing at 60 °C up to 50 h. Na2SiO3 solution-to-NaOH solution ratio and liquid-to-solid mass ratio are maintained at 1 and 0.3, respectively. The test results indicated that the compressive strength of geopolymer samples was increased with the increase in NaOH concentration from 10 M to 14 M, with the addition of Na2SiO3 solution to NaOH solution and with curing time as well. The maximum compressive strength value of 32 and 73 MPa was achieved for the geopolymer sample, namely FAG14NH and FAG14NHNS. The geopolymerization behavior and geopolymer specimen were explained by means of various techniques such as ICC, FESEM, HRTEM, XRD and FTIR. Further hardness and thermal behavior of geopolymer specimens were also studied in this investigation.

Similar content being viewed by others

References

A. Dwivedi and M.K. Jain, Fly Ash – Waste Management and Overview: A Review, Recent Res. Sci. Technol., 2014, 6(1), p 30–35.

D. Panias, I.P. Giannopoulou and T. Perraki, Effect of Synthesis Parameters on the Mechanical Properties of Fly Ash-Based Geopolymers, Colloids Surf. A Physicochem. Eng. Asp., 2007, 301, p 246–254.

P. Plants, A. Utilization, P. Plants, P. Utilities, M. Notification, and H. Court, Ash Utilization, 2013, http://www.cea.nic.in/reports/others/thermal/tcd/write_up_ash_utilization.pdf.

J.L. Provis and J.S.J. Van Deventer, Introduction to geopolymers, Geopolymers, 1940, 1(2002), p 1–11.

M.M.A. Abdullah, H. Kamarudin, H. Mohammed, I.K. Nizar, A.R. Rafiza and Y. Zarina, The Relationship of NaOH Molarity, Na2SiO3/NaOH Ratio, Fly Ash/Alkaline Activator Ratio, and Curing Temperature to the Strength of Fly Ash-Based Geopolymer, Adv. Mater. Res., 2011, 330, p 1475–1482.

D. Das and P.K. Rout, Utilization of Thermal Industry Waste: From Trash to Cash , Carbon Sci Technol., 2019, 2, p 43–48.

M.C.M. Nasvi, P.G. Ranjith, J. Sanjayan and H. Bui, Effect of Temperature on Permeability of Geopolymer: A Primary Well Sealant for Carbon Capture and Storage Wells, Fuel, 2014, 117(PART A), p 354–363. https://doi.org/10.1016/j.fuel.2013.09.007

H. Xu and J.S.J. Van Deventer, The Geopolymerisation of Alumino-Silicate Minerals, Int. J. Miner. Process., 2000, 59(3), p 247–266.

J.G.S. Van Jaarsveld, J.S.J. Van Deventer and L. Lorenzen, Factors Affecting the Immobilization of Metals in Geopolymerized Flyash, Metall. Mater. Trans. B Process Metall. Mater. Process. Sci., 1998, 29(1), p 283–291.

A. Ali, K. Azizi, Z. Man and H. Ullah, Effects of Parameters on the Setting Time of Fly Ash Based Geopolymers Using Taguchi Method, Procedia Eng., 2016, 148, p 302–307.

S.K. Nath, S. Maitra, S. Mukherjee and S. Kumar, Microstructural and Morphological Evolution of Fly Ash Based Geopolymers, Constr. Build. Mater., 2016, 111, p 758–765. https://doi.org/10.1016/j.conbuildmat.2016.02.106

D. Khale and R. Chaudhary, Mechanism of Geopolymerization and Factors Influencing Its Development: A Review, J. Mater. Sci., 2007, 42(3), p 729–746.

I. Wilińska and B. Pacewska, Comparative Investigation of Reactivity of Different Kinds of Fly Ash in Alkaline Media, J. Therm. Anal. Calorim., 2019, 4, p 3857–3872.

K. Somna, C. Jaturapitakkul, P. Kajitvichyanukul and P. Chindaprasirt, NaOH-Activated Ground Fly Ash Geopolymer Cured at Ambient Temperature, Fuel, 2011, 90(6), p 2118–2124. https://doi.org/10.1016/j.fuel.2011.01.018

T. Almusallam, Effect of Sodium Silicate to Sodium Hydroxide Ratios on Strength and Microstructure of Fly Ash Geopolymer Binder, 2014, p 4333–4339.

U. Rattanasak and P. Chindaprasirt, Influence of NaOH Solution on the Synthesis of Fly Ash Geopolymer, Miner. Eng., 2009, 22(16), p 1073–1078.

A. Sathonsaowaphak, P. Chindaprasirt and K. Pimraksa, Workability and Strength of Lignite Bottom Ash Geopolymer Mortar, J. Hazard. Mater., 2009, 168, p 44–50.

Z. Chen, Y. Liu, W. Zhu and E.H. Yang, Incinerator Bottom Ash (IBA) Aerated Geopolymer, Constr. Build. Mater., 2016, 112, p 1025–1031.

D. Hardjito, S.E. Wallah, D.M.J. Sumajouw, and B.V. Rangan, On the Development of Fly Ash-Based Geopolymer Concrete, 2005, (101), p 467–472.

R.H. Kupaei, U.J. Alengaram, M.Z. Bin Jumaat and H. Nikraz, Mix Design for Fly Ash Based Oil Palm Shell Geopolymer Lightweight Concrete, Constr. Build. Mater., 2013, 43, p 490–496.

C.E. Authority, “Flyash_201819-Firsthalf.Pdf,” n.d.

P.C. Limited, N.T. Power, H.N. Delhi, and G. Singh, NTPC Limited, 2019, p 1–11.

F.L.Y.A.S.H. Generation, I.T.S. Utilization, and I.N. The, http://www.cea.nic.in/reports/others/thermal/tcd/flyash_201718-firsthalf.pdf, 2018, 18(June).

J.G.S. Van Jaarsveld and J.S.J. Van Deventer, Effect of the Alkali Metal Activator on the Properties of Fly Ash-Based Geopolymers, Ind. Eng. Chem. Res., 1999, 38(10), p 3932–3941.

B.K. Saikia, C.R. Ward, M.L.S. Oliveira, J.C. Hower, F. De Leao, M.N. Johnston, A. O’Bryan, A. Sharma, B.P. Baruah and L.F.O. Silva, Geochemistry and Nano-Mineralogy of Feed Coals, Mine Overburden, and Coal-Derived Fly Ashes from Assam (North-East India): A Multi-Faceted Analytical Approach, Int. J. Coal Geol., 2015, 137, p 19–37. https://doi.org/10.1016/j.coal.2014.11.002

B. Singh and R.K. Goswami, Compaction Characteristics of Lateritic Soil Mixed with Fly Ash and Lime, Int. J. Geotech. Eng., 2012, 6(4), p 437–444.

R.M. Hamidi, Z. Man and K.A. Azizli, Concentration of NaOH and the Effect on the Properties of Fly Ash Based Geopolymer, Procedia Eng., 2016, 148, p 189–193. https://doi.org/10.1016/j.proeng.2016.06.568

S.K. Nath and S. Kumar, Role of Alkali Concentration on Reaction Kinetics of Fly Ash Geopolymerization, J. Non Cryst. Solids, 2018, 2019(505), p 241–251.

P. Chindaprasirt, T. Chareerat and V. Sirivivatnanon, Workability and Strength of Coarse High Calcium Fly Ash Geopolymer, Cem. Concr. Compos., 2007, 29(3), p 224–229.

L. Manjarrez, A. Nikvar-Hassani, R. Shadnia and L. Zhang, Experimental Study of Geopolymer Binder Synthesized with Copper Mine Tailings and Low-Calcium Copper Slag, J. Mater. Civ. Eng., 2019, 31(8), p 04019156.

B. Nematollahi and J. Sanjayan, Effect of Different Superplasticizers and Activator Combinations on Workability and Strength of Fly Ash Based Geopolymer, Mater. Des., 2014, 57, p 667–672.

R.A. Aguilar, O.B. Díaz and J.I.E. García, Lightweight Concretes of Activated Metakaolin-Fly Ash Binders, with Blast Furnace Slag Aggregates, Constr. Build. Mater., 2010, 24, p 1166–1175.

P. Rożek, M. Król and W. Mozgawa, Spectroscopic Studies of Fly Ash-Based Geopolymers. Spectrochim , Acta Part A Mol. Biomol. Spectrosc., 2018, 198, p 283–289.

T. Bakharev, Resistance of Geopolymer Materials to Acid Attack, Cem. Concr. Res., 2005, 35(4), p 658–670.

A. Noushini and A. Castel, The Effect of Heat-Curing on Transport Properties of Low-Calcium Fly Ash-Based Geopolymer Concrete, Constr. Build. Mater., 2016, 112, p 464–477.

A. Matsuda, I. Maruyama, A. Meawad, S. Pareek and Y. Araki, Reaction, Phases, and Microstructure of Fly Ash-Based Alkali-Activated Materials, J. Adv. Concr. Technol., 2019, 17(March), p 93–101.

T. Bakharev, Geopolymeric Materials Prepared Using Class F f Ly Ash and Elevated Temperature Curing, Cem. Concr. Res., 2005, 35, p 1224–1232.

M. Soutsos, A.P. Boyle, R. Vinai, A. Hadjierakleous and S.J. Barnett, Factors Influencing the Compressive Strength of Fly Ash Based Geopolymers, Constr. Build. Mater., 2016, 110, p 355–368.

G. Roviello, C. Menna, O. Tarallo, L. Ricciotti, C. Ferone, D. Asprone, and R. Cioffi, Lightweight Geopolymer-Based Hybrid Materials, 2017.

P. Duxson, J.L. Provis, G.C. Lukey, S.W. Mallicoat, W.M. Kriven and J.S.J. Van Deventer, Understanding the Relationship between Geopolymer Composition, Microstructure and Mechanical Properties, Colloids Surf. A Physicochem. Eng. Asp., 2005, 269(1–3), p 47–58.

A. Fauzi, M. Fadhil, A.B. Malkawi, M. Mustafa and A. Bakri, Study of Fly Ash Characterization as a Cementitious Material, Procedia Eng., 2016, 148, p 487–493.

E.I. Diaz, E.N. Allouche and S. Eklund, Factors Affecting the Suitability of Fly Ash as Source Material for Geopolymers, Fuel, 2010, 89(5), p 992–996. https://doi.org/10.1016/j.fuel.2009.09.012

S. Alehyen, M.E.L. Achouri and M. Taibi, Characterization, Microstructure and Properties of Fly Ash-Based Geopolymer, J. Mater. Environ. Sci., 2017, 8(5), p 1783–1796.

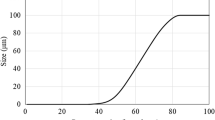

S.K. Nath and S. Kumar, Reaction Kinetics of Fly Ash Geopolymerization: Role of Particle Size Controlled by Using Ball Mill, Adv. Powder Technol., 2019, 30(5), p 1079–1088.

S. Kumar, F. Kristály and G. Mucsi, Geopolymerisation Behaviour of Size Fractioned Fly Ash, Adv. Powder Technol., 2015, 26(1), p 24–30.

D.A. Fungaro, M. Valério, I. De Pesquisas, I.C. Sp and S. Paulo, Utilization of Water Treatment Plant Sludge and Coal Fly Ash in Brick Manufacturing, Am. J. Environ. Prot., 2014, 2(5), p 83–88.

I. Ismail, S.A. Bernal, J.L. Provis, R. San, S. Hamdan and J.S.J. Van Deventer, Modification of Phase Evolution in Alkali-Activated Blast Furnace Slag by the Incorporation of Fly Ash, Cem. Concr. Compos., 2014, 45, p 125–135.

P. Sukmak, K. Kunchariyakun, G. Sukmak, S. Horpibulsuk, S. Kassawat and A. Arulrajah, Strength and Microstructure of Palm Oil Fuel Ash-Fly Ash-Soft Soil Geopolymer Masonry Units, J. Mater. Civ. Eng., 2019, 31(8), p 1–13.

S. Alehyen, M.E.L. Achouri and M. Taibi, Characterization, Microstructure and Properties of Fly Ash-Based Geopolymer, J. Mater. Environ. Sci., 2017, 8(5), p 1783–1796.

V. Stelzhammer, S. Ozcan, G. Michael, H. Steeb, G.E. Hodes, C. Guest, H. Rahmoune, E.H.F. Wong, J. Russo and S. Bahn, Behavior of Low-Calcium Fly and Bottom Ash-Based Geopolymer Concrete Cured at Ambient Temperature, Diagn. Neuropsychiatry, 2015 https://doi.org/10.1016/j.dineu.2015.08.001

M. Komljenović, Z. Baščarević and V. Bradić, Mechanical and Microstructural Properties of Alkali-Activated Fly Ash Geopolymers, J. Hazard. Mater., 2010, 181(1–3), p 35–42.

A. Ściubidło, I. Majchrzak-Kucęba and W. Nowak, Characterization of Fly Ash from Polish Coal-Fired CHP Plants for NO2 Capture, Polish J. Environ. Stud., 2019, 28(6), p 4403–4416.

G.V.P. Bhagath Singh and K.V.L. Subramaniam, Characterization of Indian Fly Ashes Using Different Experimental Techniques, Indian Concr. J., 2018, 92(3), p 10–23.

R.S. Blissett and N.A. Rowson, A Review of the Multi-Component Utilisation of Coal Fly Ash, Fuel, 2012, 97, p 1–23.

S.V. Vassilev, R. Menendez, D. Alvarez, M. Diaz-Somoano and M.R. Martinez-Tarazona, Phase-Mineral and Chemical Composition of Coal Fly Ashes as a Basis for Their Multicomponent Utilization. 1. Characterization of Feed Coals and Fly Ashes, Fuel, 2003, 82(14), p 1793–1811.

S.K. Nath, S. Mukherjee, S. Maitra and S. Kumar, Kinetics Study of Geopolymerization of Fly Ash Using Isothermal Conduction Calorimetry, J. Therm. Anal. Calorim., 2017, 127(3), p 1953–1961.

X. Gao, Q.L. Yu and H.J.H. Brouwers, Reaction Kinetics, Gel Character and Strength of Ambient Temperature Cured Alkali Activated Slag-Fly Ash Blends, Constr. Build. Mater., 2015, 80, p 105–115.

M.B. Ogundiran and S. Kumar, Synthesis and Characterisation of Geopolymer from Nigerian Clay, Appl. Clay Sci., 2015, 108, p 173–181.

J.J. Ekaputri and S. Junaedi, Effect of Curing Temperature and Fiber on Metakaolin-Based Geopolymer, Procedia Eng., 2017, 171, p 572–583.

N. Muhammad, Effect of Heat Curing Temperatures on Fly Ash-Based Geopolymer Concrete Effect of Heat Curing Temperatures on Fly Ash-Based Geopolymer Concrete, 2019, (January), p 0–5.

M. Kaur, J. Singh, and M. Kaur, Author ’ s Accepted Manuscript Synthesis of Fly Ash Based Geopolymer Mortar Combinations of Alkaline Activator Solution Reference: To Appear in: Ceramics International, 2017.

C.D. Atis, O. Karahan and E.B.G. Avs, Influence of Duration of Heat Curing and Extra Rest Period after Heat Curing on the Strength and Transport Characteristic of Alkali Activated Class F Fly Ash Geopolymer Mortar, Constr. Build. Mater., 2017, 151, p 363–369.

W. Lee, J. Wang, Y. Ding and T. Cheng, A Study on the Characteristics and Microstructures of GGBS/FA Based Geopolymer Paste and Concrete, Constr. Build. Mater., 2019, 211, p 807–813.

Z. Baˇ and V. Bradi, Mechanical and Microstructural Properties of Alkali-Activated Fly Ash Geopolymers, J. Hazard. Mater., 2010, 181, p 35–42.

M. Kaur, J. Singh, and M. Kaur, Author ’ s Accepted Manuscript Synthesis of Fly Ash Based Geopolymer Mortar Combinations of Alkaline Activator Solution Reference: To Appear in: Ceramic Internationl, Ceram. Int., 2017, doi:https://doi.org/10.1016/j.ceramint.2017.10.071.

K. Strecker, L.F. Tonholo and C.T. Lombardi, Effect of Curing Temperature, Activator Solution Composition and Particle Size in Brazilian Fly-Ash Based Geopolymer, Production, 2019, 22, p 1–12.

M.T. Ghafoor, Q.S. Khan, A.U. Qazi, M.N. Sheikh, and M.N.S. Hadi, Influence of Alkaline Activators on the Mechanical Properties of Fly Ash Based Geopolymer Concrete Cured at Ambient Temperature, 2020, (xxxx).

P. Nath and P.K. Sarker, Flexural Strength and Elastic Modulus of Ambient-Cured Blended Low-Calcium Fly Ash Geopolymer Concrete, Constr. Build. Mater., 2017, 130, p 22–31. https://doi.org/10.1016/j.conbuildmat.2016.11.034

N. Aida Mohd Mortar, H. Kamarudin, R.A. Rafiza, T.A.F. Meor and M. Rosnita, Compressive Strength of Fly Ash Geopolymer Concrete by Varying Sodium Hydroxide Molarity and Aggregate to Binder Ratio , IOP Conf. Ser. Mater. Sci. Eng., 2020, 864(1), p 012037.

E. Ul Haq, S. Kunjalukkal Padmanabhan and A. Licciulli, Synthesis and Characteristics of Fly Ash and Bottom Ash Based Geopolymers—A Comparative Study, Ceram. Int., 2014, 40(2), p 2965–2971. https://doi.org/10.1016/j.ceramint.2013.10.012

H. Zhu, G. Liang, J. Xu, Q. Wu and M. Zhai, Influence of Rice Husk Ash on the Waterproof Properties of Ultrafine Fly Ash Based Geopolymer, Constr. Build. Mater., 2019, 208, p 394–401. https://doi.org/10.1016/j.conbuildmat.2019.03.035

P. Duan, C. Yan and W. Zhou, Influence of Partial Replacement of Fly Ash by Metakaolin on Mechanical Properties and Microstructure of Fly Ash Geopolymer Paste Exposed to Sulfate Attack, Ceram. Int., 2015 https://doi.org/10.1016/j.ceramint.2015.10.154

B. Yan, P. Duan and D. Ren, Mechanical Strength, Surface Abrasion Resistance and Microstructure of Fly Ash-Metakaolin-Sepiolite Geopolymer Composites, Ceram. Int., 2017, 43(1), p 1052–1060. https://doi.org/10.1016/j.ceramint.2016.10.039

S. Yousefi Oderji, B. Chen and S.T.A. Jaffar, Effects of Relative Humidity on the Properties of Fly Ash-Based Geopolymers, Constr. Build. Mater., 2017, 153, p 268–273.

S. Zeng and J. Wang, Characterization of Mechanical and Electric Properties of Geopolymers Synthesized Using Four Locally Available Fly Ashes, Constr. Build. Mater., 2016, 121, p 386–399.

N.P.R.T. Revathi, Micro-Structural Characterization of Activating Solution with Siliceous Species on Chemical Reactivity of Geopolymer by Advanced Analytical Techniques TEM, Asian J. Chem., 2018, 30(18), p 2424–2430.

W.D.A. Rickard, J. Temuujin and A. Van Riessen, Thermal Analysis of Geopolymer Pastes Synthesised from Five Fly Ashes of Variable Composition, J. Non. Cryst. Solids, 2012, 358(15), p 1830–1839.

M. Criado, A. Palomo and A. Fernández-Jiménez, Alkali Activation of Fly Ashes. Part 1: Effect of Curing Conditions on the Carbonation of the Reaction Products, Fuel, 2005, 84(16), p 2048–2054.

A. Matsuda, I. Maruyama, A. Meawad, S. Pareek and Y. Araki, Reaction, Phases, and Microstructure of Fly Ash-Based Alkali-Activated Materials, J. Adv. Concr. Technol., 2019, 17(3), p 93–101.

M.S. Morsy, S.H. Alsayed, Y. Al-Salloum and T. Almusallam, Effect of Sodium Silicate to Sodium Hydroxide Ratios on Strength and Microstructure of Fly Ash Geopolymer Binder, Arab. J. Sci. Eng., 2014, 39(6), p 4333–4339.

E. Arioz, O. Arioz and O.M. Kockar, Geopolymer Synthesis with Low Sodium Hydroxide Concentration, Iran. J. Sci. Technol. Trans. Civ. Eng., 2020 https://doi.org/10.1007/s40996-019-00336-1

J.G. Jang and H.K. Lee, Effect of Fly Ash Characteristics on Delayed High-Strength Development of Geopolymers, Constr. Build. Mater., 2016, 102, p 260–269.

D. Zaharaki, K. Komnitsas and V. Perdikatsis, Use of Analytical Techniques for Identification of Inorganic Polymer Gel Composition, J. Mater. Sci., 2010, 45(10), p 2715–2724.

H. Cheng-Yong, L. Yun-Ming, M.M.A.B. Abdullah and K. Hussin, Thermal Resistance Variations of Fly Ash Geopolymers: Foaming Responses, Sci. Rep., 2017, 7(February), p 1–11.

A. Hassan, M. Arif and M. Shariq, Mechanical Behaviour and Microstructural Investigation of Geopolymer Concrete After Exposure to Elevated Temperatures, Arab. J. Sci. Eng., 2020, 45(5), p 3843–3861. https://doi.org/10.1007/s13369-019-04269-9

D.L.Y. Kong, J.G. Sanjayan and K. Sagoe-Crentsil, Comparative Performance of Geopolymers Made with Metakaolin and Fly Ash after Exposure to Elevated Temperatures, Cem. Concr. Res., 2007, 37(12), p 1583–1589.

Z. Yang, R. Mocadlo, M. Zhao, R.D. Sisson, M. Tao and J. Liang, Preparation of a Geopolymer from Red Mud Slurry and Class F Fly Ash and Its Behavior at Elevated Temperatures, Constr. Build. Mater., 2019, 221, p 308–317. https://doi.org/10.1016/j.conbuildmat.2019.06.034

F. Škvára, R. Šcul, Z. Tišler, P. Skřičík, V. Šmilauer and Z.Z. Cílová, Preparation and Properties of Fly Ash-Based Geopolymer Foams, Ceram. Silikaty, 2014, 58(3), p 188–197.

P.N. Lemougna, K.J.D. MacKenzie and U.F.C. Melo, Synthesis and Thermal Properties of Inorganic Polymers (Geopolymers) for Structural and Refractory Applications from Volcanic Ash, Ceram. Int., 2011, 37(8), p 3011–3018.

E.D. Un and C. Géopolymère, Sédiments De Dragage Elaboration of Geopolymer Cement Based on Dredged Sediment, J. Mater. Eng. Struct., 2019, 6(1), p 1–7.

P. Payakaniti, N. Chuewangkam, R. Yensano, S. Pinitsoontorn and P. Chindaprasirt, Changes in Compressive Strength, Microstructure and Magnetic Properties of a High-Calcium Fly Ash Geopolymer Subjected to High Temperatures, Constr. Build. Mater., 2020, 265, p 120650. https://doi.org/10.1016/j.conbuildmat.2020.120650

A.M. Rashad and S.R. Zeedan, The Effect of Activator Concentration on the Residual Strength of Alkali-Activated Fly Ash Pastes Subjected to Thermal Load, Constr. Build. Mater., 2011, 25(7), p 3098–3107. https://doi.org/10.1016/j.conbuildmat.2010.12.044

G. Kürklü, The Effect of High Temperature on the Design of Blast Furnace Slag and Coarse Fly Ash-Based Geopolymer Mortar, Compos. Part B Eng., 2016, 92, p 9–18. https://doi.org/10.1016/j.compositesb.2016.02.043

S.M. Park, J.G. Jang, N.K. Lee and H.K. Lee, Physicochemical Properties of Binder Gel in Alkali-Activated Fly Ash/Slag Exposed to High Temperatures, Cem. Concr. Res., 2016, 89, p 72–79. https://doi.org/10.1016/j.cemconres.2016.08.004

F.U.A. Shaikh and V. Vimonsatit, Compressive strength of fly-ash-based geopolymer concrete at elevated temperatures. FIRE Mater., 2014. https://doi.org/10.1002/fam.2240

T. Yang, Q. Wu, H. Zhu and Z. Zhang, Geopolymer with Improved Thermal Stability by Incorporating High-Magnesium Nickel Slag, Constr. Build. Mater., 2017, 155, p 475–484. https://doi.org/10.1016/j.conbuildmat.2017.08.081

Acknowledgments

The authors are grateful to the G.B. Pant National Institute of Himalayan Environment and Sustainable Development (IERP funded), Government of India, for supporting the project entitled “Production of Geopolymer based construction material from Fly ash: An industrial waste.” We are very thankful to Mr. Ekonthung Ngullie (DGM) and his team at NTPC Limited, Bongaigaon, Assam, India, for providing us fly ash powder to carry out the present investigation. The authors are also very much thankful to the Central Instrumentation Centre (CIC), Tripura University (A Central University), Agartala, Tripura, India, for allowing us to avail of the facilities of FESEM. We acknowledge the Central Research Facility (CRF), Indian Institute of Technology, Kharagpur, for the use of HRTEM facility, Central Instrumentation Facility (CIF), National Institute of Technology, Silchar, for the use of XRD facility and Technical Cell Central Equipment Facility, S. N. Bose National Centre for Basic Sciences, Kolkata, for TGA-DTA analysis.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Das, D., Rout, P.K. Synthesis, Characterization and Properties of Fly Ash Based Geopolymer Materials. J. of Materi Eng and Perform 30, 3213–3231 (2021). https://doi.org/10.1007/s11665-021-05647-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05647-x