Abstract

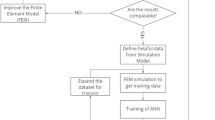

Martempering is a widely practiced industrial heat treatment process to harden steel parts with minimum distortion. A numerical experiment to predict hardness distribution in AISI 4140 steel cylinders of various diameters during martempering is presented in this work. Apart from the diameter (D), the effect of other process variables such as heat transfer coefficient (h), bath temperature (Tb), and residence time (tr) was also studied. The relationship between hardness distribution and the aforementioned process variables was highly nonlinear. An artificial neural network (ANN) model with a single hidden layer and 30 hidden layer neurons was thus developed to predict the hardness distribution in martempered AISI 4140 steel cylinders. The increase in bath temperature, diameter, and residence time decreased the average hardness, and an increase in the heat transfer coefficient increased the average hardness of martempered AISI 4140 cylinders. The weights of the ANN model were used to calculate the relative importance of all input variables and they followed a decreasing order of Tb>D>tr>h.

Similar content being viewed by others

References

G.E. Totten, C.E. Bates, and N.A. Clinton Eds., Handbook of Quenchants and Quenching Technology, ASM International, Berlin, 1993

ASM International, ASM Handbook, vol 4: Heat Treating.

S.W. Dean, B. Liščić, S. Singer and B. Smoljan, Prediction of Quench-Hardness within the Whole Volume of Axially Symmetric Workpieces of Any Shape, J. ASTM Int., 2010, 7(2), p 102647. https://doi.org/10.1520/JAI102647

B. Smoljan, D. Iljkić and N. Tomašić, Computer Simulation of Mechanical Properties of Quenched and Tempered Steel Specimen, J. Achiev. Mater. Manuf. Eng., 2010, 40(2), p 6.

K.M. Pranesh Rao and K.N. Prabhu, Assessment of Wetting Kinematics and Cooling Performance of Select Vegetable Oils and Mineral-Vegetable Oil Blend Quench Media, Mater. Sci. Forum, 2015, 830–831, p 160–163.

H.M. Tensi, Prediction of Hardness Profile in Workpiece Based on Characteristic Cooling Parameters and Material Behaviour During Cooling, Quenching Theory and Technology, 2nd ed., B. Lisicic, H.M. Tensi, L.C.F. Canale Ed., CRC Press, Cambridge, 2010, p 359–443

K.M. Pranesh Rao and K. Narayan Prabhu, Effect of Bath Temperature on Cooling Performance of Molten Eutectic NaNO3-KNO3 Quench Medium for Martempering of Steels, Metall. Mater. Trans. A, 2017, 48(10), p 4895–4904. https://doi.org/10.1007/s11661-017-4267-7

A. Zehtab Yazdi, S.A. Sajjadi, S.M. Zebarjad and S.M. Moosavi Nezhad, Prediction of Hardness at Different Points of Jominy Specimen Using Quench Factor Analysis Method, J. Mater. Process. Technol., 2008, 199(1–3), p 124–129. https://doi.org/10.1016/j.jmatprotec.2007.08.035

C. Şimşir and C.H. Gür, A FEM Based Framework for Simulation of Thermal Treatments: Application to Steel Quenching, Comput. Mater. Sci., 2008, 44, p 588–600. https://doi.org/10.1016/j.commatsci.2008.04.021

C. Şimşir and C.H. Gür, 3D FEM Simulation of Steel Quenching and Investigation of the Effect of Asymmetric Geometry on Residual Stress Distribution, J. Mater. Process. Technol., 2008, 207(1–3), p 211–221. https://doi.org/10.1016/j.jmatprotec.2007.12.074

K. Babu and T.S. Prasanna Kumar, Comparison of Austenite Decomposition Models During Finite Element Simulation of Water Quenching and Air Cooling of AISI 4140 Steel, Metall. Mater. Trans. B, 2014, 45(4), p 1530–1544. https://doi.org/10.1007/s11663-014-0069-0

J Mat Pro. Sente Software Ltd, Surrey Research Park.

T. Kasuya and H. Hashiba, “Carbon Equivalent to Assess Hardenability of Steel and Prediction of HAZ Hardness Distribution,” Nippon Steel Technical, 2007.

F. Huyan, P. Hedström, L. Höglund and A. Borgenstam, A Thermodynamic-Based Model to Predict the Fraction of Martensite in Steels, Metall. Mater. Trans. A, 2016, 47(9), p 4404–4410. https://doi.org/10.1007/s11661-016-3604-6

C.P. Kothandaraman and S. Subramayan, Heat and Mass Transfer Data Book, 7th ed. New Age International publishers, Cambridge, 2010.

D.H. Herring, Industrial Gases/Combustion: A Review of Gas Quenching from the Perspective of the Heat Transfer Coefficient, Sente Software Ltd, Surrey Research Park, United Kingdom, 2006.

Matlab. Mathworks, Natick, Massachusetts, United States.

O.M. Ibrahim, A Comparison of Methods for Assessing the Relative Importance of Input Variables in Artificial Neural Networks, J. Appl. Sci. Res., 2013, 9(11), p 5692–5700. https://doi.org/10.1067/mmt.2002.123333

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rao, K.M.P., Prabhu, K.N. Numerical Simulation to Predict the Effect of Process Parameters on Hardness during Martempering of AISI4140 Steel. J. of Materi Eng and Perform 30, 3416–3435 (2021). https://doi.org/10.1007/s11665-021-05630-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05630-6