Abstract

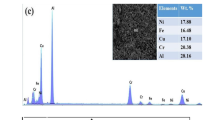

In this work, gas tungsten arc weld was employed to produce corrosion-resistant Ni claddings on the surface of Inconel 617. The effect of isothermal aging on the microstructure of Ni claddings was studied at 850 °C for up to 3000 h. Results show that isothermal aging can promote the release of welding residual stress. Recrystallization begins to appear in the Ni claddings when the aging time reaches 2000 h. Hardness values and chemical compositions of Ni claddings are changed slightly during the whole aging process. TiN phase is precipitated in the Ni claddings before and after isothermal aging, while their quantity and morphology do not change significantly. Low chromium concentration and extremely low chromium diffusion coefficient in Ni claddings indicate that the Ni claddings have excellent corrosion resistance to molten salts.

Similar content being viewed by others

References

J. Serp, M. Allibert, O. Beneš, S. Delpech, O. Feynberg, V. Ghetta, D. Heuer, D. Holcomb, V. Ignatiev, J.L. Kloosterman, L. Luzzi, E. Merle-Lucotte, J. Uhlíř, R. Yoshioka, and Z. Dai, The Molten Salt Reactor (MSR) in Generation IV: Overview and Perspectives, Prog. Nucl. Energ., 2014, 77, p 308–319.

D.F. Williams and K.T. Clarno, Evaluation of Salt Coolants for Reactor Applications, Nucl. Technol., 2008, 163(3), p 330–343.

G.S. Was, D. Petti, S. Ukai, and S. Zinkle, Materials For Future Nuclear Energy Systems, J. Nucl. Mater., 2019, 527, p 151837.

W. Ren, G. Muralidharan, D.F. Wilson, and D.E. Holcomb, Considerations of Alloy N for Fluoride Salt-Cooled High-Temperature Reactor Applications, Proceedings of the Asme Pressure Vessels and Piping Conference, 2011, p 57029

H.E. McCoy, The INOR-8 Story, Oak Ridge Nat. Lab. Rev., 1969, 3(2), p 35–48.

W.J. Ren, Considerations of Alloy 617 Application in the Gen IV Nuclear Reactor Systems—Part I: Mechanical Property Challenges, Proceedings of the ASME Pressure Vessels and Piping Conference (PVP2009), D.L. Rudland, Ed., ASME, 2009, 77313

W.J. Ren, Considerations of Alloy 617 Application in the Gen IV Nuclear Reactor Systems—Part II: Metallurgical Property Challenges, Proceedings of the ASME Pressure Vessels and Piping Conference (PVP2009). D.L. Rudland Ed., ASME, 2009, p 78146

B. Wilson, Alloy 617 Makes the Grade, https://www.thermofisher.com/blog/metals/alloy-617-makes-the-grade/

L. Olson, Material Corrosion in Molten LiF-NaF-KF Eutectic Salt, Ph. D. dissertation, University of Wisconsin-Madison, WI, 2009

L.C. Olson, J.W. Ambrosek, K. Sridharan, M.H. Anderson, and T.R. Allen, Materials Corrosion in Molten LiF-NaF-KF salt, J. Fluor. Chem., 2009, 130(1), p 67–73.

J.W. Ambrosek, Molten Chloride Salts for Heat Transfer in Nuclear Systems, Ph.D. Dissertation, University of Wisconsin-Madison, 2011

L. Olson, K. Sridharan, M. Anderson, and T. Allen, Nickel-Plating for Active Metal Dissolution Resistance in Molten Fluoride Salts, J. Nucl. Mater., 2011, 411(1–3), p 51–59.

Q. Dai, X.-X. Ye, H. Ai, S. Chen, L. Jiang, J. Liang, K. Yu, B. Leng, Z. Li, and X. Zhou, Corrosion of Incoloy 800H Alloys with Nickel Cladding in FLiNaK Salts at 850 °C, Corros. Sci., 2018, 133, p 349–357.

G. Muralidharan, D.F. Wilson, L.R. Walker, M.L. Santella, and D.E. Holcomb, Cladding Alloys for Fluoride Salt Compatibility Final Report, 2011

Fluoride-Salt-Cooled High Temperature Reactor (FHR) Materials, Fuels and Components White Paper, Integrated Research Project Workshop 3, 2012,

J. DuPont and A. Marder, Thermal Efficiency of Arc Welding Processes, Weld J, 1995, 74(12), p 406s.

K. Nakamura and M. Yashima, Crystal Structure of NaCl-type Transition Metal Monocarbides MC (M=V, Ti, Nb, Ta, Hf, Zr), a Neutron Powder Diffraction Study, Mater. Sci. Eng. B, 2008, 148(1), p 69–72.

K. Aigner, W. Lengauer, D. Rafaja, and P. Ettmayer, Lattice Parameters and Thermal Expansion of Ti(CxN1−x), Zr(CxN1−x), Hf(CxN1−x) and TiN1−x from 298 to 1473 K as Investigated by High-Temperature X-ray Diffraction, J. Alloys Compd., 1994, 215(1), p 121–126.

R. Mendoza, J. Camacho, G. Lugo, C. Lopez, L. Herrera, J. Reyes, C. Gonalez, and J.A. Juarez-Islas, Structure of a Low Carbon Al-killed/Ti-Added Steel, ISIJ Int., 1997, 37(2), p 176–180.

X. Shi, K. Yu, L. Jiang, C. Li, Z. Li, and X. Zhou, Microstructural Characterization of Ni-201 Weld Cladding onto 304 Stainless Steel, Surf. Coat. Technol., 2018, 334, p 19–28.

J. Moon, C. Lee, S. Uhm, and J. Lee, Coarsening Kinetics of TiN Particle in a Low Alloyed Steel in Weld HAZ: Considering Critical Particle Size, Acta Mater., 2006, 54(4), p 1053–1061.

H.-H. Jin, J.-H. Shim, Y.W. Cho, and H.-C. Lee, Formation of Intragranular Acicular Ferrite Grains in a Ti-Containing Low Carbon Steel, ISIJ Int., 2003, 43(7), p 1111–1113.

J.N. DuPont, J.C. Lippold, and S.D. Kiser, Welding Metallurgy and Weldability of Nickel-Base Alloys, Wiley, 2009, p 100–143

F.-Y. Ouyang, C.-H. Chang, and J.-J. Kai, Long-Term Corrosion Behaviors of Hastelloy-N and Hastelloy-B3 in Moisture-Containing Molten FLiNaK Salt Environments, J. Nucl. Mater., 2014, 446(1–3), p 81–89.

Acknowledgments

This work was supported by the Youth Innovation Promotion Association CAS (Grant No. 2020260), the National Key Research and Development Program of China (Grant No. 2017YFA0402800), Science and Technology Innovation 2025 Major Project of Ningbo (Grant No. 2019B10084) and the Strategic Priority Research Program of the Chinese Academy of Sciences (Grant No. XDA02004210).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, L., Han, F., Chen, S. et al. Effect of Isothermal Aging on Microstructure Evolution of Ni Claddings on Inconel 617. J. of Materi Eng and Perform 30, 2389–2398 (2021). https://doi.org/10.1007/s11665-021-05629-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05629-z