Abstract

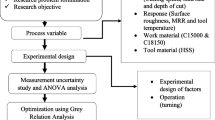

Product quality and efficiency are critical phenomena for every manufacturing unit to survive the pressure of the present days. This situation demands to develop a new cutting tool for industrial application. Hence, the current work aims to study the performance characteristics of the newly powder metallurgy (P/M) made Fe-1% C-1% W-1% Ti and Fe-1% C-2% W-1% Ti cutting tools under the turning of AISI 1020 low carbon steel and AA 6061 aluminum alloy through powder metallurgy (P/M) route. The working parameters such as cutting speed, feed rate and depth of cut were varied in the experiments as per Taguchi's L9 orthogonal array. With each set of experiments, the surface roughness, tool wear and tooltip temperature were measured as response parameters. The experiments were carried out on two different work materials (hard and soft) under the same cutting conditions. Response tables on means of responses and signal-to-noise ratios of responses were employed to analyze the experimental results and to determine the contribution of process parameters to the output characteristics. The experimental results reveal that cutting speed is ranked one in effecting the tooltip temperature, and feed rate is ranked one for effecting surface roughness. The P/M alloy tool with 2% W has a marginally better performance than a tool with 1% W due to the enhanced hardness of the tool from 65 HRC to 83 HRC by the addition of tungsten, which causes the formation of hard phases such as martensite and carbides in the alloy system.

Similar content being viewed by others

References

B. Mills and A.H. Redford, Tool Materials, Machinability of Engineering Materials. Springer, Dordrecht, 1983, p 59–92. https://doi.org/10.1007/978-94-009-6631-4_4

S.A. Kurlov and A.I. Gusev, Tungsten Carbides: Structure, Properties and Application in Hardmetals. Springer Series in Materials Science, Vol 184 Springer, Cham, 2013.

R.T. Fox and R. Nilsson, Binderless Tungsten Carbide Carbon Control with Pressure-Less Sintering, Int. J. Refract. Met. Hard Mater., 2018, 76, p 82–89.

B. Varaprasad, C. Srinivasa Rao, and P.V. Vinay, Effect of Machining Parameters on Tool Wear in Hard Turning of AISI D3 Steel, Procedia Eng., 2014, 97, p 338–345.

A. Salak, K. Vasiko, M. Selecka, and H. Danninger, New Short Time Face Turning Method for Testing the Machinability of PM Steels, J. Mater. Process. Technol., 2006, 176, p 62–69.

O. Ozbek and H. Saruhan, The Effect of Vibration and cutting Zone Temperature on Surface Roughness and Tool Wear in Eco-friendly MQL Turning of AISI D2, J. Mater. Res. Technol., 2020, 9(3), p 2762–2772.

A. Cicek, F. Kara, T. Kıvak, E. Ekici, and I. Uygur, Effects of Deep Cryogenic Treatment on the Wear Resistance and Mechanical Properties of AISI H13 Hot Work Tool Steel, J. Mater. Eng. Perform., 2015, 24, p 4431–4439.

F. Kara, M. Karabatak, M. Ayyıldız, and E. Nas, Effect of Machinability, Microstructure and Hardness of Deep Cryogenic Treatment in Hard Turning of AISI D2 Steel with Ceramic Cutting, J. Mater. Res. Technol., 2020, 9(1), p 969–983.

N.R. Dhar and M. Kamruzzaman, Cutting Temperature, Tool Wear, Surface Roughness and Dimensional Deviation in Turning AISI-4037 Steel Under Cryogenic Condition, Int. J. Mach. Tools Manuf, 2007, 47, p 754–759.

N.L. Bhirud and R.R. Gawande, Measurement and Prediction of Cutting Temperatures During Dry Milling: Review and Discussions, J Braz. Soc. Mech. Sci. Eng., 2017, 39, p 5135–5158.

N.A. Abukhshim, P.T. Mativenga, and M.A. Sheikh, Heat generation and temperature prediction in metal cutting: a review and implications for high speed machining, Int J Mach Tools Manuf., 2006, 46(7–8), p 782–800.

D.O. Sullivan and M. Cotterell, Workpiece Temperature Measurement in Machining, Proc. Inst. Mech. Eng., 2002, 216(Part B), p 135–139.

J.C. Heigel, E. Whitenton, B. Lane, M.A. Donmez, V. Madhavan, and W. Moscoso-Kingsley, Infrared Measurement of the Temperature at the Tool–Chip Interface While Machining Ti–6Al–4V, J. Mater. Process. Technol., 2017, 243, p 123–130.

J.C. Garcia-Gonzalez, W. Moscoso-Kingsley, and V. Madhavan, Tool Rake Face Temperature Distribution When Machining Ti6Al4V and Inconel 718, Procedia Manuf., 2016, 5, p 1369–1381.

M.B. da Silva and J. Wallbank, Cutting Temperature: Prediction and Measurement Methods—A Review, J. Mater. Process. Technol., 1999, 88, p 195–202.

H. Mzad, A Simple Mathematical Procedure to Estimate Heat Flux in Machining Using Measured Surface Temperature with Infrared Laser, Case Stud. Therm. Eng., 2015, 6, p 128–135.

C.K. Toh, Comparison of Chip Surface Temperature Between Up and Down Milling Orientations in High Speed Rough Milling of Hardened Steel, J. Mater. Process. Technol., 2005, 167(1), p 110–118.

S. Kosarajua and S. Chandrekar, Taguchi Analysis on Cutting Force and Surface Roughness in Turning MDN350 steel, 4th International Conference on Materials Processing and Characterisation Materials today: Proceedings, Vol 2, 2015, p 3383–3393

S.K. Nayak, J.K. Patro, S. Dewangan, and S. Gangopadhyay, Multi-Objective Optimization of Machining Parameters During Dry Turning of AISI 304 Austenitic Stainless Steel Using Grey Relational Analysis, 3rd International Conference on Materials Processing and Characterization Materials Today: Proceedings, Vol 6, 2014, p 201–208

C. Shoba, N. Ramanaiah, and D.N. Rao, Optimizing the Machining Parameters for Minimum Surface Roughness in Turning Al6%,Sic6% RHA Hybrid Composites, International Conference on Material Processing and Characterization Material Today: Proceedings, Vol. 10, 2015, p 220–229

E. Nas and N. AltanÖzbek, Optimization of the Machining Parameters in Turning of Hardened Hot Work Tool Steel Using Cryogenically Treated Tools, Surf. Rev. Lett., 2020, 27(05), p 1950177.

F. Kara, U. Koklu, and U. Kabasakaloğlu, Taguchi Optimization of Surface Roughness in Grinding of Cryogenically Treated AISI 5140 Steel, Mater. Test., 2020, 62(10), p 1041–1047.

G. Yingfei, P.M. de Escalona, and A. Galloway, Influence of Cutting Parameters and Tool Wear on the Surface Integrity of Cobalt-Based Stellite 6 Alloy When Machined Under a Dry Cutting Environment, J. Mater. Eng. Perform., 2017, 26, p 312–326.

T.K. Kandavel and T. Panneerselvam, Experimental Investigations on Tribological Behavior and Cutting Tool Performance of Sinter-Forged Cu, Mo and Ti Added Plain Carbon Steel, Int. J. Mach. Mach. Mater., 2016, 18(3), p 201–212.

T. Panneerselvam, T.K. Kandavel, and P. Kishore, Experimental Investigation on Cutting Tool Performance of Newly Synthesized P/M Alloy Steel Under Turning Operation, Arab. J. Sci. Eng., 2019, 44, p 5801–5809.

S.S. Prabhu, S. Prathiba, N. Mittal, S. MK, M.S. Babu, and K. Vignesh, Experimental Study on Cutting Tool Wear Behaviour of Sintered/Extruded P/M Alloy Steels, Int. J. ChemTech Res., 2015, 8(2), p 822–828.

A. Dadgari, D. Huo, and D. Swailes, Investigation on Tool Wear and Tool Life Prediction in Micro-Milling of Ti-6Al-4V, Nanotechnol. Precision Eng., 2018, 1, p 218–225.

W. Grzesik, P. Nieslony, W. Habrat, J. Sieniawski, and P. Laskowski, Investigation of Tool Wear in the Turning of Inconel 718 Superalloy in Terms of Process Performance and Productivity Enhancement, Tribol. Int., 2018, 118, p 337–346.

S. Tooptong, K.-H. Park, and P. Kwon, A Comparative Investigation on Flank Wear When Turning Three Cast Irons, Tribol. Int., 2018, 120, p 127–139.

I.P. Okokpujie, O.S. Ohunakin, C.A. Bolu, and K.O. Okokpujie, Experimental Data-set for Prediction of Tool Wear During Turning of Al-1061 Alloy by High Speed Steel Cutting Tools, Data Brief, 2018, 18, p 1196–1203.

X. Zha, F. Jiang, and X. Xu, Investigating the High Frequency Fatigue Failure Mechanisms of Mono and Multilayer PVD Coatings by the Cyclic Impact Tests, Surf. Coat. Technol., 2018, 344, p 689–701.

T.K. Kandavel, T. AshokKumar, and E. Varmban, Prediction of Tribological Characteristics of Powder Metallurgy Ti and W Added Low Alloy Steels Using Artificial Neural Network, Indian J. Eng. Mater. Sci., 2020, 27, p 503–517.

Acknowledgment

Authors express their sincere gratitude to The Vice-Chancellor, SASTRA Deemed to be University, for granting permission and support extended to carry out the work successfully.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Panneerselvam, T., Kandavel, T.K., Sreenivas, S.A. et al. Effects of Working Parameters on Performance Characteristics of Cutting Tools Processed through Powder Metallurgy under Turning Operation. J. of Materi Eng and Perform 30, 2890–2898 (2021). https://doi.org/10.1007/s11665-021-05622-6

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05622-6