Abstract

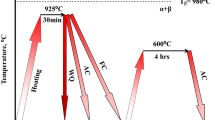

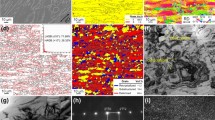

The microstructure and hardness of Ti-6Al-4V alloys were evaluated before and after aging to investigate the effect of the cooling rate at the solution treatment stage of the solution treatment and aging (STA) process for aerospace components. The cooling rate distribution across a Ti-6Al-4V alloy sample representing practical STA process of an aerospace fan disk component was estimated using finite element analysis. The Ti-6Al-4V alloy specimens were solution-treated with the obtained cooling rates, and aged. Experimental WQ of the Ti-6Al-4V alloy specimen in the solution treatment facilitated the retention of the primary α phase, while the β phase was transformed to α′. Controlled cooling at slower rates compared to WQ led to the formation of coarser globular α and the transformation of β to α+β lamellae. Subsequent aging of the specimens led to the observation of α+β lamellae in all specimens regardless of the cooling conditions, where the average thickness of the plates in lamellae was higher at slower cooling rates. The specimens exhibited higher hardness values when cooled more quickly at the solution treatment, which was attributed to the formation of thinner α plates and/or a higher α′ fraction. The hardness value of all specimens increased further after aging, regardless of the cooling conditions, due to precipitation of Ti3Al in the α phase and/or fine α plates from the α′ phase.

Similar content being viewed by others

References

S. Patil, S. Kekade, K. Phapale, S. Jadhav, A. Powar, A. Supare, R. Singh, Effect of α and β Phase Volume Fraction on Machining Characteristics of Titanium Alloy Ti6Al4V, Procedia Manuf., 2016, 6, p 63–70.

L.W. Meyer, L. Krüger, K. Sommer, T. Halle, M. Hockauf, Dynamic Strength and Failure Behavior of Titanium Alloy Ti-6Al-4V for a Variation of Heat Treatments, Mech. Time-Dependent Mater., 2008, 12(3), p 237–247.

I. Inagaki, T. Takechi, Y. Shirai, N. Ariyasu, Application and Features of Titanium for the Aerospace Industry, 106, Nippon Steel & Sumitomo metal technical report, Nippon Steel, 2014, p 22–27.

J. Foltz, ASM handbook volume 4E, G.E. Totten, D.S. Machenzie (eds), Heat Treating of Nonferrous Alloys. ASM International, USA, 2016, Introduction to Titanium and Its Alloys, p 481–497.

R. Boyer, E.W. Collings, G. Welsch Eds., Materials Properties Handbook: Titanium Alloys, ASM International, USA, 1994, p 528–530

AMS, Titanium Alloy, 6.0Al-4.0V, Solution Heat Treated and Aged, SAE Specification, 4965m, 2018.

C. Carson, ASM handbook Volume 4E, G.E. Totten, D.S. Machenzie (eds), Heat Treating of Nonferrous Alloys. ASM International, USA, 2016, Heat treating of Titanium and Titanium alloys, p 511–533.

A. Gupta, R.K. Khatirkar, A. Kumar, M.S. Parihar, Investigations on the Effect of Heating Temperature and Cooling Rate on Evolution of Microstructure in an α + β Titanium Alloy, J. Mater. Res., 2018, 33(8), p 946–957.

M.T. Jovanović, S. Tadić, S. Zec, Z. Mišković, I. Bobić, The Effect of Annealing Temperatures and Cooling Rates on Microstructure and Mechanical Properties of Investment Cast Ti-6Al-4V Alloy, Mater. Des., 2006, 27(3), p 192–199.

R. Boyer and J. Foltz, ASM handbook volume 4E, G.E. Totten, D.S. Machenzie (eds), Heat Treating of Nonferrous Alloys. ASM International, USA, 2016, Metallurgy of titanium alloy heat treatment, p 498–509.

G. Welsch, G. Lütjering, K. Gazioglu, W. Bunk, Deformation Characteristics of Age Hardened Ti-6Al-4V, Metall. Trans. A, 1977, 8(1), p 169–177.

T. Morita, K. Hatsuoka, T. Iizuka, K. Kawasaki, Strengthening of Ti–6Al–4V Alloy by Short-Time Duplex Heat Treatment, Mater. Trans., 2005, 46(7), p 1681–1686.

S.T. Oh, K.D. Woo, J.H. Kim, S.M. Kwak, Effect of Retained β Phase on Mechanical Properties of Cast Ti-6Al-4V Alloy, Mater. Trans., 2017, 58(8), p 1145–1149.

S. Tanaka, T. Morita, K. Shinoda, Effects of Short Time Duplex Heat Treatment on Microstructure and Fatigue Strength of Ti-6Al-4V alloy, ICF, 2013, 13, p 16–21.

Y.C. Lin, Y. Tang, Y.Q. Jiang, J. Chen, D. Wang, D.G. He, Precipitation of Secondary Phase and Phase Transformation Behavior of a Solution-Treated Ti-6Al-4V Alloy During High-Temperature Aging, Adv. Eng. Mater., 2020, 22(5), p 1901436.

G. Lütjering, J.C. Williams, Titanium, 2nd ed., B. Derby (ed.), Springer-Verlag, Berlin, 2007, p 203–215.

P. Pinke, L. Claplovic, T. Kovacs, The Influence of Heat Treatment on the Microstructure of the Casted Ti6Al4V Titanium Alloy, Slovak University of Technology, Bratislava, Web, p. 11, 2011.

R.K. Gupta, V.A. Kumar, S. Chhangani, Study on Variants of Solution Treatment and Aging Cycle of Titanium Alloy Ti6Al4V, J. Mater. Eng. Perform., 2016, 25(4), p 1492–1501.

Y. Ren, S.M. Zhou, Z.Y. Xue, W.B. Luo, Y.J. Ren, Y.J. Zhang, Effect of α-Platelet Thickness on the Mechanical Properties of Ti-6Al-4V Alloy with Lamellar Microstructure, IOP Conf. Ser. Mater. Sci. Eng., 2017, 281(1), p 012024.

JMaPro version 7.0.0, Sente Software Corp., Guildford, UK, 2012.

S.J. Oh, I.J. Shon, S.J. Lee, Effect of Milling Time and Addition of PCA on Austenite Stability of Fe-7%Mn Alloy, J. Korean Powder Metall. Inst., 2018, 25(2), p 126–131.

T. Suzuki, M. Wuttig, Analogy Between Spinodal Decomposition and Martensitic Transformation, Acta Metall., 1975, 23(9), p 1069–1076.

J. Zhang, D. Li, Preferred Precipitation of Ordered α2 Phase at Dislocations and Boundaries in Near-α Titanium Alloys, Mater. Sci. Eng., 2003, 341(1–2), p 229–235.

Acknowledgments

The authors gratefully acknowledge the extended support provided to this work by the Lightweight Material National Strategy Project (10081335) funded by the Korea Evaluation Institute of Industrial Technology (KEIT).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Seo, S., Choi, H., Lee, G. et al. Effect of Cooling Rate on Microstructure and Hardness during Solution Treatment and Aging Process of Ti-6Al-4V Alloy for Aerospace Components. J. of Materi Eng and Perform 30, 3406–3415 (2021). https://doi.org/10.1007/s11665-021-05618-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05618-2