Abstract

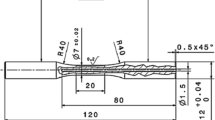

In this paper, an experimental and numerical study of the fatigue life of 2024-T351 aluminum alloy has been investigated. For this purpose, mechanical properties of the material are obtained by tensile test. The Manson–Coffin–Basquin equation is used to estimate the fatigue life. The specimen surface is photographed using a microscope camera to examine the specimen deformation. The ratio of white to black pixels on the specimen surface that changes during loading is investigated using the image processing method. Changes in the ratio of white to black pixels indicate that material fatigue is associated with the specimen surface. The experiments are strain-controlled and in 6 different strain amplitudes on the specimens. Then, by obtaining the amplitude range of elastic and plastic strains in the stress–strain hysteresis loop, the coefficients of the Manson–Coffin–Basquin equation are calculated in a stable cycle. Using these coefficients, the Manson–Coffin–Basquin equation is presented to estimate the fatigue life of the material in an amplitude of different strains. A comparison of the results of this equation and the experimental results show a good agreement.

taken from the surface of the specimen in the strain amplitude range of 4%; (a) N = 1, (b) N = 6, (c) N = 11, (d) N = 33

Similar content being viewed by others

References

M. Hadipour, F. Alambeigi, R. Hosseini, and R. Masoudinejad, A Study on the Vibrational Effects of Adding an Auxiliary Chassis to a 6-Ton Truck, J. Amer. Sci., 2011, 7(6), p 1219–1226

M. Nejad, R.K. Farhangdoost and M. Shariati, Numerical Study on Fatigue Crack Growth in Railway Wheels Under the Influence of Residual Stresses, Eng. Fail. Anal., 2015, 52, p 75–89.

R. Masoudi Nejad, Using Three-Dimensional Finite Element Analysis for Simulation of Residual Stresses in Railway Wheels, Eng. Fail. Anal., 2014, 45, p 449–455.

S.M. Salehi, G.H. Farrahi, S. Sohrabpoor and N.R. Masoudi, Life Estimation in the Railway Wheels under the Influence of Residual Stress Field, Int. J. Railw. Res., 2014, 1(1), p 53–60.

D. Ghahremani Moghadam, K. Farhangdoost and R. Masoudi Nejad, Microstructure and Residual Stress Distributions Under the Influence of Welding Speed in Friction Stir Welded 2024 Aluminum Alloy, Metall. Mater. Trans. B, 2016, 47(3), p 2048–2062.

L.P. Borrego, L.M. Abreu, J.M. Costa and J.M. Ferreira, Analysis of Low Cycle Fatigue in AlMgSi Aluminium Alloys, Eng. Fail. Anal., 2004, 11, p 715–725.

S. Khan, O. Kintzel and J. Mosler, Experimental and Numerical Lifetime Assessment of Al 2024 Sheet, Int. J. Fatigue, 2012, 37, p 112–122.

C.S. Lee, M.H. Kim, M.S. Chun, T.K. Lee, and J.M. Lee, Fatigue damage model for numerical assessment of fatigue characteristics, In Materials Science Forum, 2008, p 663–666

J. Howell, A. Telang, J.G. Lee, S. Choi and K.N. Subramanian, Surface damage accumulation in Sn–Ag solder joints under large reversed strains, J. Mater. Sci.: Mater. Electron., 2002, 13, p 335–344.

A.F. Blom, A. Hedlund, W. Zhao, A. Fathulla, B. Weiss, and R. Stickler, Short fatigue crack growth behaviour in Al2024 and Al7475, In EGF1, 2013.

Y.C. Lin, X.M. Chen, Z.H. Liu and J. Chen, Investigation of Uniaxial Low-Cycle Fatigue Failure Behavior of Hot-Rolled AZ91 Magnesium Alloy, Int. J. Fatigue, 2013, 48, p 122–132.

Y. Xiong and Y. Jiang, Fatigue of ZK60 Magnesium Alloy Under Uniaxial Loading, Int. J. Fatigue, 2014, 64, p 74–83.

X. Cai and J. Xu, A Generalized Life Evaluation Formula for Uniaxial and Multiaxial Static Fatigue, Ceram. Int., 2016, 42, p 3212–3218.

J. Dallmeier, O. Huber, H. Saage and K. Eigenfeld, Uniaxial Cyclic Deformation and Fatigue Behavior of AM50 Magnesium Alloy Sheet Metals Under Symmetric and Asymmetric Loadings, Mater. Des., 2015, 70, p 10–30.

S. Maya-Johnson, A.J. Ramirez and A. Toro, Fatigue Crack Growth Rate of Two Pearlitic Rail Steels, Eng. Fract. Mech., 2015, 138, p 63–72.

R. Masoudi Nejad, Rolling Contact Fatigue Analysis Under Influence of Residual Stresses. M.S. thesis, Sharif University of Technology, School of Mechanical Engineering, 2013

R. Masoudi Nejad, S.M. Salehi, and G.H. Farrahi. Simulation of railroad crack growth life under the influence of combination mechanical contact and thermal loads, in 3rd International Conference on Recent Advances in Railway Engineering, Iran, (2013)

R. Masoudi Nejad, S.M. Salehi, G.H. Farrahi, and M. Chamani. Simulation of crack propagation of fatigue in Iran rail road wheels and Effect of residual stresses, in Proceedings of the 21st International Conference on Mechanical Engineering, Iran, 2013

M. Nejad, M.S. Reza and Kh. Farhangdoost, 3D Finite Element Simulation of Residual Stresses in UIC60 Rails During the Quenching Process, Therm. Sci., 2017, 21(3), p 1301–1307.

K. Shiotani, T. Matsui, M. Fujigaki, and Y. Morimoto, Strain measurement using three spherical waves in digital holography, in 11th International Congress and Exhibition on Experimental and Applied Mechanics, vol. 3, 2008, p 1365–1372

Y. Li, D. Wang, G. Wang, Y. Zhang, and C. Liu, Measurement of temperature field in the region near to the radiator by using digital holography, in International Symposium on Photoelectronic Detection and Imaging 2009, 2009, p 738240–738240-8

Y.Y. Hung and J.Q. Wang, Dual-beam Phase Shift Shearography for Measurement of in-Plane Strains, Opt. Lasers Eng., 1996, 24, p 403–413.

M.Y.Y. Hung, K.W. Long and J.Q. Wang, Measurement of Residual Stress by Phase Shift Shearography, Opt. Lasers Eng., 1997, 27, p 61–73.

W. Steinchen, G. Kupfer, P. Mäckel and F. Vössing, Determination of Strain Distribution by Means of Digital Shearography, Measurement, 1999, 26, p 79–90.

R.M. Groves, S.W. James, S.E. Barnes, S. Fu, D. Furfari, P.E. Irving, and R.P. Tatam, Multicomponent laser shearography for the investigation of defects in rotating machinery, in Photonics Europe. International Society for Optics and Photonics, 2004, p 546–556

F. Groves, J. Barnes, I. Fu, D. Furfari, P.E. Irving, R.P. Tatam, et al., Full-field laser shearography instrumentation for the detection and characterization of fatigue cracks in titanium 10-2-3, in Journal of ASTM International. vol. 3, ed: ASTM International, 2006, p. 1–13

L. Yang, P.R. Samala, S. Liu, K.W. Long and Y.L. Lee, Measurement of Nugget Size of Spot Weld by Digital Shearography, Optics Photonics, 2005, 588008–588016, p 2005.

J.L. Chen, C. Sun, Y. W. Qin, and X.H. Ji, Damage evaluation of subsurface defect in sandwich by phase-shifting digital shearography, in Key Engineering Materials, 2006, p 399–404

G.P. Zou, J. Lu and W.W. Wang, Application of Electronic Shearography Speckle Pattern Interferometry to Nundestructive Testing of Wood Material, J. Harb. Eng. Univ., 2009, 30, p 357–361.

R. Masoudi Nejad, M. Shariati and K. Farhangdoost, Effect of Wear on Rolling Contact Fatigue Crack Growth in Rails, Tribol. Int., 2016, 94, p 118–125.

R. Masoudi Nejad Three-dimensional analysis of rolling contact fatigue crack and life prediction in railway wheels and rails under residual stresses and wear, Ph.d. thesis, Ferdowsi University of Mashhad, School of Mechanical Engineering, 2017

R. Masoudi Nejad, M. Shariati, K. Farhangdoost and A. Atrian, Rolling Contact Fatigue Analysis of Rails Under the Influence of Residual Stresses Induced by Manufacturing, Sci. Iran., 2018, 26(3), p 1427–1437.

R. Masoudi Nejad, K. Farhangdoost and M. Shariati, Microstructural analysis and fatigue fracture behavior of rail steel, Mech. Adv. Mater. Struct., 2020, 27(2), p 152–164.

K. Aliakbari, M. Imanparast and R. Masoudi Nejad, Microstructure and Fatigue Fracture Mechanism for a Heavy-Duty Truck Diesel Engine Crankshaft, Sci. Iran., 2019, 26(6), p 3313–3324.

T. Takahashi, S. Hioki, I. Shohji and O. Kamiya, Fatigue Damage Evaluation by Surface Feature for Sn-3.5 Ag and Sn-0.7 Cu Solders, Mater. Trans., 2005, 46, p 2335–2343.

F. Diaz, G. Kaufmann, A. Armas and G. Galizzi, Optical Measurement of the Plastic Zone Size in a Notched Metal Specimen Subjected to Low-Cycle Fatigue, Opt. Lasers Eng., 2001, 35, p 325–333.

S. Vanlanduit, J. Vanherzeele, R. Longo and P. Guillaume, A Digital Image Correlation Method for Fatigue Test Experiments, Opt. Lasers Eng., 2009, 47, p 371–378.

C. Kanchanomai, Y. Miyashita and Y. Mutoh, Low-Cycle Fatigue Behavior and Mechanisms of a Lead-Free Solder 96.5 Sn/3.5 Ag, J. Electron. Mater., 2002, 31, p 142–151.

P. Lopez Crespo, B. Moreno, A. Lopez Moreno and J. Zapatero, Characterisation of Crack-Tip Fields In Biaxial Fatigue Based on High-Magnification Image Correlation and Electro-Spray Technique, Int. J. Fatigue, 2015, 71, p 17–25.

D.L.B.R. Jurjo, C. Magluta, N. Roitman and P.B. Gonçalves, Analysis of the Structural Behavior of a Membrane Using Digital Image Processing, Mech. Syst. Signal Process., 2015, 54, p 394–404.

M. Shariati, M. Mirzaei and R.M. Nejad, An Applied Method for Fatigue Life Assessment of Engineering Components Using Rigid-Insert Crack Closure Model, Eng. Fract. Mech., 2018, 204, p 421–433.

M. Nejad, Kh. Reza, Farhangdoost and M. Shariati, Three-Dimensional Simulation of Rolling Contact Fatigue Crack Growth in UIC60 Rails, Tribol. Trans., 2016, 59(6), p 1059–1069.

M. Nejad, Kh. Reza, M.S. Farhangdoost and M. Moavenian, Stress Intensity Factors Evaluation for Rolling Contact Fatigue Cracks in Rails, Tribol. Trans., 2017, 60(4), p 645–652.

M. Shariati and R.M. Nejad, Fatigue Strength and Fatigue Fracture Mechanism for Spot Welds in U-Shape Specimens., Latin Am. J. Solids Struct., 2016, 13(15), p 2787–2801.

M. Shariati, E. Mohammadi and R. Masoudi Nejad, Effect of a New Specimen Size on Fatigue Crack Growth Behavior in Thick-Walled Pressure Vessels, Int. J. Press. Vessels Piping, 2017, 150, p 1–10.

R. Masoudi Nejad, M. Shariati and K. Farhangdoost, Prediction of fatigue crack propagation and fractography of rail steel, Theor. Appl. Fract. Mech., 2019, 101, p 320–331.

R. Hossein Ghasemi, M. Nejad, A.J. Darbandi, Y.T. Beni, and M. Shariati, Fatigue and Fracture Behavior of A516 Steel Used in Thick-Walled Pressure Vessels. Sci. Iran., 2019. just-accepted

A. Saber, M. Shariati and R. Masoudi Nejad, Experimental and Numerical Investigation of Effect of Size, Position and Geometry of Some Cutouts on Fatigue Life and Crack Growth Path on AISI1045 Steel Plate, Theor. Appl. Fract. Mech., 2020, 107, p 102506.

Reza Masoudi Nejad, Numerical Study on Rolling Contact Fatigue in Rail Steel Under the Influence of Periodic Overload, Eng. Fail. Anal., 2020, 115, p 104624.

R. Masoudi Nejad, M. Tohidi, A.J. Darbandi, A. Saber, and M. Shariati, Experimental and Numerical Investigation of Fatigue Crack Growth Behavior and Optimizing Fatigue Life of Riveted Joints in Al-Alloy 2024 Plates. Theor. Appl. Fract. Mech., 2020

A. Standard, "E606-92, Standard Practice for Strain-Controlled Fatigue Testing, Annual Book of ASTM Standards, vol. 3, 2004

L. Coffin Jr, The Problem of Thermal Stress Fatigue in Austenitic Steels at Elevated Temperatures, Knolls Atomic Power Lab., 1954

S.S. Manson, Behavior of Materials Under Conditions of Thermal Stress, NACA TN 2933, 1953

Y.R. Luo, C.X. Huang, G.U.O. Yi and Q.Y. Wang, Energy-Based Prediction of Low Cycle Fatigue Life of High-Strength Structural Steel, J. Iron Steel Res. Int., 2012, 19, p 47–53.

F. Ellyin, Cyclic Strain Energy Density as a Criterion for Multiaxial Fatigue Failure, in ICBMFF2, 2013

R.C. Gonzalez, Digital Image Processing. Pearson Education India, 2009

G.R. Halford and S.S. Manson, Fatigue and Durability of Structural of Material, ASM International press, United States of America, New York, 2006, p 434

Acknowledgment

Reza Masoudi Nejad is supported by the International Postdoctoral Exchange Fellowship Program (Talent-Introduction Program) of the People’s Republic of China (Fund No. 234384).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chabouk, E., Shariati, M., Kadkhodayan, M. et al. Fatigue Assessment of 2024-T351 Aluminum Alloy Under Uniaxial Cyclic Loading. J. of Materi Eng and Perform 30, 2864–2875 (2021). https://doi.org/10.1007/s11665-021-05613-7

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05613-7