Abstract

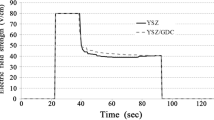

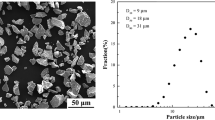

Herein, NiCr was coated on γ-TiAl via the hollow cathode glow discharge, whereas yttria stabilized zirconia (YSZ) was coated on the NiCr by multi-arc ion plating. A strong bonding between the two coatings and substrate, i.e., NiCr, YSZ, and γ-TiAl occurred. However, the surface of YSZ coating displayed macroparticles of different sizes, which affected the oxidation resistance. High-temperature oxidation behavior of YSZ/NiCr coating was investigated at 850, 950, and 1050 °C. The results showed that the oxidation kinetics of YSZ/NiCr coating followed the parabolic law. Moreover, the YSZ coating did not showed a phase transition, consisting of t-ZrO2 and c-ZrO2. After 100 h of oxidation at 850 and 950 °C, macrocracks appeared on the surface of macroparticles. Yet, a thermally grown TGO oxide layer of Cr2O3 with a thickness of 2-4 μm effectively inhibited the oxidation of YSZ/NiCr coating. However, when the temperature increased to 1050 °C, the number and size of microcracks on the macroparticles surface increased and reached the YSZ coating surface from different directions, resulting in a high degree of oxidation. The oxidation kinetics and oxide scales formed during the test indicated that the YSZ/NiCr coating effectively improved the oxidation resistance of γ-TiAl at 850, 950, and 1050 °C. However, since the microcracks formed on the macroparticles caused a severe oxidation, the effect of the macroparticles on the oxidation of YSZ/NiCr coating at high temperature could not be ignored.

Similar content being viewed by others

References

B.P. Bewlay, T.K. Weimer, A.. Suzki and P.R. Subramanian, The Science, Technology and Implementation of Tial Alloys in Commercial Aircraft Engines, Mater Res Soc Symp Proc, 2013, 1516, p 49–58.

G.L. Chen, L.L. Zhao, J.P. Lin and X.J. Xu, Recent Progress in High Temperature TiAl Alloys, Mat Fabr Prop Charact Model, 2011, 2, p 547–555.

B.P. Bewlay, S. Nag, A. Suzuki and M.J. Weimer, TiAl Alloys in Commercial Aircraft Engines, Mater. High Temp., 2016 https://doi.org/10.1080/09603409.2016.1183068

K.Y. Durgarao, M. Kumawat and S. Banumathy, Microstructure, Oxidation and Mechanical Properties of a Diffusion Aluminide (Al3Ti ) Coated Lamellar γ -TiAl Alloy, Surf. Coat. Technol., 2019 https://doi.org/10.1016/j.surfcoat.2019.125071

D.J. Kim, D.Y. Seo, H. Saari, T. Sawatzky and Y. Kim, Intermetallics Isothermal Oxidation Behavior of Powder Metallurgy Beta Gamma TiAl-2Nb-2Mo Alloy, Intermetallics, 2011, 19, p 1509–1516.

M. Yoshihara and Y. Kim, Oxidation Behavior of Gamma Alloys Designed for High Temperature Applications, Intermetallics, 2005, 13, p 952–958.

P. Raluca, S. Friedle and M. Schütze, Oxidation Protection of γ-TiAl-Based Alloys-A Review, Intermetallics, 2015, 56, p 1–14.

A. Brotzu, F. Felli and D. Pilone, Effect of Alloying Elements on the Behaviour of TiAl-Based Alloys, Intermetallics, 2014, 54, p 176–180.

F. Wang, Z. Tang and W. Wu, Effect of Chromium on the Oxidation Resistance of TiAl, Intermetallics, 1997, 48, p 381–390.

S. Nouri, S. Sahmani, M. Asayesh and M. Mohammadi, Microstructural Characterization of YSZ-CoNiCrAlY Two-Layered Thermal Barrier Coating Formed on γ -TiAl Intermetallic Alloy via APS Process, Intermetallics, 2020, 118, p 106704.

H.L. Du, A. Aljarany, P.K. Datta, and J.S. Burnell-Gray, Oxidation Behaviour of Ti-46.7Al-1.9W-0.5Si in Air and Ar-20% O2 Between 750 and 950°C, Corros. Sci., 2005, 47, p 1706–1723.

S. Nath, I. Manna and J.D. Majumdar, Kinetics and Mechanism of Isothermal Oxidation of Compositionally Graded Yttria Stabilized Zirconia (YSZ) Based Thermal Barrier Coating, Corros. Sci., 2014, 88, p 10–22.

S. Nath, I. Manna, A.K. Jha, S.C. Sharma, S.K. Pratihar and J. Dutta Majumdar, Thermophysical Behavior of Thermal Sprayed Yttria Stabilized Zirconia Based Composite Coatings, Ceram. Int., 2017, 43, p 11204–11217.

M.J. Liu, G.R. Li, G.J. Yang and C.J. Li, Structural Regulation and High Thermal Insulation Mechanism of Thermal Barrier Coatings Prepared by Plasma Spray-Physical Vapor Deposition ( PS-PVD ), J. Xiangtan Univ. (Nat. Sci. edn.), 2019, 06, p 1–36.

K. Mert, Y. Ozgurluk, H. Ahlatci and A. Cahit, Evaluation of Oxidation and Thermal Cyclic Behavior of YSZ, Gd2Zr2O7 and YSZ/Gd2Zr2O7 TBCs, Surf. Coat. Technol., 2019, 371, p 262–275.

S. Tailor, R. Upadhyaya, S.Y. Manjunath, A.V. Dub, A. Modi and S.C. Modi, Atmospheric Plasma Sprayed 7%-YSZ Thick Thermal Barrier Coatings with Controlled Segmentation Crack Densities and Its Thermal Cycling Behavior, Ceram. Int., 2018, 44, p 2691–2699.

M. Tabeshfar, M. Salehi, G. Dini, P. Inge, M. Einarsrud, K. Wiik, M. Salehi and G. Dini, Hot Corrosion of Gd2Zr2O7, Gd2Zr2O7/YbSZ, YSZ+Gd2Zr2O7/YbSZ and YSZ Thermal Barrier Coatings Exposed to Na2SO4+V2O5, Surf. Coat. Technol., 2020, 3, p 126718.

M. Li, L. Guo and F. Ye, Phase Structure and Thermal Conductivities of Er2O3 Stabilized ZrO2 Toughened Gd2Zr2O7 Ceramics for Thermal Barrier Coatings, Ceram. Int., 2016, 42, p 16584–16588.

X.F. Jiang, Q.C. Liu and H.B. Wang, Technology and Application of Multi-Arc Ion Plating, J. Chongqing Univ., 2006, 29, p 52–55.

Z. Xu, X. Liu, P. Zhang, Y. Zhang, G. Zhang and Z. He, Double Glow Plasma Surface Alloying and Plasma Nitriding, Surf. Coat. Technol., 2007, 201, p 4822–4825.

S. Yuan, N. Lin, Q. Zeng, H. Zhang, X. Liu, Z. Wang and Y. Wu, Recent Developments in Research of Double Glow Plasma Surface Alloying Technology: A Brief Review, Integr. Med. Res., 2020 https://doi.org/10.1016/j.jmrt.2020.03.123

D.B. Wei, P.Z. Zhang, Z.J. Yao, X.F. Wei, J.T. Zhou and X.H. Chen, Oxidation behaviour of plasma surface alloying on Ti6Al4V alloy, Surf. Eng., 2016. doi:https://doi.org/10.1179/1743294415Y.0000000095.

K. Bobzin, T. Brögelmann, C. Kalscheuer and T. Liang, High Temperature Oxidation Protection of γ-Titanium Aluminide Using (Cr, Al)ON Coatings Deposited by High-Speed Physical Vapor Deposition, Surf. Coat. Technol., 2017, 332, p 2–11.

U. Zwicker and E. Kalsch, Crack of Titanium Alloys Under Stress During Oxidation in Air, Sci. Technol. Appl. Titan., 2000, 2, p 29–306.

I. Kratochvílová, P. Ashcheulov, J. Škarohlíd, R. Škoda, J. Kopeček, P. Sajdl, J. Macák, M. Lajčinová, A. Nováková, J. Neethling, A. Janse van Vuuren, S. Ngongo, P. Xu, J. Lorinčík and M. Steinbrück, Zr Alloy Protection Against High-Temperature Oxidation: Coating by a Double-Layered Structure with Active and Passive Functional Properties, Corros. Sci., 2019, 163, p 108270.

H. Wang, Z. Qi, H. Yu, Z. Zhang and G. Min, Effect of Aluminium and Silicon on High Temperature Oxidation Resistance of Fe-Cr-Ni Heat Resistant Steel, Trans. Tianjin Univ., 2010, 15, p 457–462.

Z.Y. Wei and H.N. Cai, Comprehensive Effect of TGO Growth on the Stress Characteristic and Delamination Mechanism in Lamellar Structure Thermal Barrier Coatings, Ceram. Int., 2020, 46, p 2220–2237.

Acknowledgment

This project was supported by Natural Science Foundation for Excellent Young Scientists of Jiangsu Province, China (Grant No. BK20180068), China Postdoctoral Science Foundation funded project (Grant No. 2018M630555), Opening Project of Materials Preparation and Protection for Harsh Environment Key Laboratory of Ministry of Industry and Information Technology (Grant No. XCA20013-1).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, F., Wei, D., Liang, H. et al. Oxidation Mechanism of YSZ/NiCr Coating Prepared by Hollow Cathode Glow Discharge Phenomenon and Multi-arc Ion Plating. J. of Materi Eng and Perform 30, 2832–2842 (2021). https://doi.org/10.1007/s11665-021-05598-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05598-3