Abstract

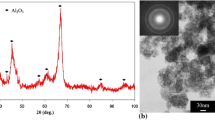

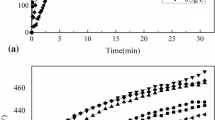

Dense outer layer with inter-oxide composite intermediate layer coatings was formed on Al-356 matrix with Nb2O5 reinforcement particles composite via soft-sparking power duty cycle plasma electrolytic oxidation (PEO) in alkaline silicate electrolyte. The x-ray diffraction and transmission electron microscopy results proved the formation of γ-alumina layer containing Nb-Al mixed oxides. The band and discrete pores at and near the metal/coating interface were reduced by applying bipolar-soft power cycle duty discharges with higher negative half cycles. The applied mixed oxide coating showed high corrosion resistance in aggressive and corrosive mediums specially during the long-time exposure tests. This behavior was associated with the triple layered PEO coating, containing very few open channels from metal substrate to the outer layers. The high surface hardness, small surface roughness, and low surface frictions ensure high wear and abrasion resistance of the coatings.

Similar content being viewed by others

References

A. Pohl, Wear Resistant Sintered Aluminium Parts for Automotive Applications, Powder Metall., 2006, 49(2), p 104–106. https://doi.org/10.1179/174329006X115984

S.B. Shabel and D.A. Granger, Friction and Wear of Aluminum-Silicon Alloys, ASM Handbook. P.J. Blau Ed., Springer, Berlin, 2021, p 785–794

E. Diego, R. D. Lozano, M. Solís, Wear Mechanisms Experienced by an Automotive Grade Al-Si-Cu Alloy Under Sliding Conditions, Ingenier. mecáni. tecnolog. desarroll vol.5 no.3 México sep. (2015).

B. Lidia, Enhancement in Sustained Friction and Wear Resistance of Nanoporous Aluminum Oxide Films Obtained by Controlled Electrochemical Oxidation Process, RSC Adv., 2019, 9, p 25056–25063. https://doi.org/10.1039/C9RA05702A

M. Djafri, M. Bouchetara, C. Busch, S. Khatir, T. Khatir, S. Weber, K. Shbaita and M. Abdel Wahab, Influence of Thermal Fatigue on the Wear Behavior of Brake Discs Sliding against Organic and Semimetallic Friction Materials, Tribol. Trans., 2018, 61(5), p 861–868. https://doi.org/10.1080/10402004.2018.1437491

N.E. Udoye and O.S.I. Fayomi, Assessment of Wear Resistance of Aluminium Alloy in Manufacturing Industry-A Review, Proc. Manuf., 2019, 35(2019), p 1383–1386. https://doi.org/10.1016/j.promfg.2019.09.007

P. Kishore, Wear Analysis of Al 5052 Alloy with Varying Percentage of Tungsten Carbide, AIP Conf. Proc., 2019, 2128, p 040003. https://doi.org/10.1063/1.5117965

R. Pramod, G.B.V. Kumar, P.S.S. Gouda and A.T. Mathew, A Study on the Al2O3 reinforced Al7075 Metal Matrix Composites Wear behavior using Artificial Neural Networks, Mater. Today Proc., 2018, 5(5), p 11376–11385. https://doi.org/10.1016/j.matpr.2018.02.105

H. Sakthisudhan, S. Jose and K. Manisekar, Dry Sliding Wear Behaviour of Single and Dual Ceramic Reinforcements Premixed with Al Powder in AA6061 Matrix, J. Mater. Res. Technol., 2021 https://doi.org/10.1016/j.jmrt.2018.01.005

A.V. Skazochkin and G.G. Bondarenko, Research of Surface Wear Resistance of Aluminum Alloy Modified with Minerals using Sclerometry Method, Dev. Methods Measur., 2019, 10, p 263–270. https://doi.org/10.21122/2220-9506-2019-10-3-263-270

H. Alrobei, Effect of Different Parameters and Aging Time on Wear Resistance and Hardness of SiC-B4C Reinforced AA6061 Alloy, J. Mech. Sci. Technol., 2020, 34, p 2027–2034. https://doi.org/10.1007/s12206-020-0424-9

Z. Jin, L. Zhu and H. Wang, Microstructures and Wear Resistance of Al-25 wt.%Si Coatings Prepared by High-Efficiency Supersonic Plasma Spraying, J. Therm. Spray. Technol., 2019, 28, p 1308–1317. https://doi.org/10.1007/s11666-019-00898-6

S. Peddavarapu and R.J. Bharathi, Dry Sliding Wear Behaviour of AA6082-5%SiC AND AA6082-5%TiB2 Metal Matrix Composites, Mater. Today Proc., 2018, 5(6), p 14507–14511. https://doi.org/10.1016/j.matpr.2018.03.038

T.W. Clyne and S.C. Troughton, A Review of Recent Work on Discharge Characteristics During Plasma Electrolytic Oxidation of Various Metals, Int. Mater. Rev., 2019, 64, p 127–162. https://doi.org/10.1080/09506608.2018.1466492

W. Gebarowski and S. Pietrzyk, Influence of the Cathodic Pulse on the Formation and Morphology of Oxide Coatings on Aluminium Produced by Plasma Electrolytic Oxidation, Arch. Metall. Mater., 2013, 58(1), p 241–245. https://doi.org/10.2478/v10172-012-0180-7

S. Wang, X. Liu, X. Yin and N. Du, Influence of Electrolyte Components on the Microstructure and Growth Mechanism of Plasma Electrolytic Oxidation Coatings on 1060 Aluminum Alloy, Surf. Coat. Tech., 2020, 381, p 125214. https://doi.org/10.1016/j.surfcoat.2019.125214

Q.B. Li, C.C. Liu, W.B. Yang and J. Liang, Growth Mechanism and Adhesion of PEO Coatings on 2024Al Alloy, Surf. Eng., 2016, 15, p 760–766. https://doi.org/10.1080/02670844.2016.1200860

W. Gębarowski and S. Pietrzyk, Growth Characteristics of the Oxide Layer on Aluminium in the Process of Plasma Electrolytic Oxidation, Arch. Metall. Mater., 2014, 59(1), p 1–5. https://doi.org/10.2478/amm-2014-0070

A.R. Fatkullin, E.V. Parfenov, A. Yerokhin, D.M. Lazarev and A. Matthews, Effect of Positive and Negative Pulse Voltages on Surface Properties and Equivalent Circuit of the Plasma Electrolytic Oxidation Process, Surf. Coatings Technol., 2015 https://doi.org/10.1016/j.surfcoat.2015.07.075

A. Nominé, J. Martin, C. Noël, G. Henrion, T. Belmonte, I.V. Bardin and P. Lukeš, Surface Charge at the Oxide/Electrolyte Interface: Toward Optimization of Electrolyte Composition for Treatment of Aluminum and Magnesium by Plasma Electrolytic Oxidation, Langmuir, 2016, 32(5), p 1405–1409. https://doi.org/10.1021/acs.langmuir.5b03873

A. Nominé, J. Martin, C. Noël, G. Henrion, T. Belmonte, I.V. Bardin, V.L. Kovalev and G. Rakoch, The Evidence of Cathodic Micro-Discharges during Plasma Electrolytic Oxidation Process, Appl. Phys. Lett., 2014, 104(8), p 81603. https://doi.org/10.1063/1.486642

A.G. Rakoch, A.A. Gladkova, Z. Linn and D.M. Strekalina, The Evidence of Cathodic Micro-Discharges during Plasma Electrolytic Oxidation of Light Metallic Alloys and Micro-Discharge Intensity Depending on pH of the Electrolyte, Surf. Coat. Technol., 2015, 269, p 138–144. https://doi.org/10.1016/j.surfcoat.2015.02.026

J. Martin, P. Haraux, V. Ntomprougkidis, S. Migot, S. Bruyère and G. Henrion, Characterization of Metal Oxide Micro/nanoparticles Elaborated by Plasma Electrolytic Oxidation of Aluminium and Zirconium Alloys, Surf. Coat. Technol., 2020, 397, p 125987. https://doi.org/10.1016/j.surfcoat.2020.125987

W. Zhang, B. Tian, K. Du, H. Zhang and F. Wang, Preparation and Corrosion Performance of PEO Coating With Low Porosity on Magnesium Alloy AZ91D In Acidic KF System, Int. J. Electrochem. Sci., 2011, 6, p 5228–5248.

F. Tjiang, L.W. Ye, Y.J. Huang, C.C. Chou and D.S. Tsai, Effect of Processing Parameters on Soft Regime Behavior of Plasma Electrolytic Oxidation of Magnesium, Ceram. Int., 2017, 43, p 567–572. https://doi.org/10.1016/j.ceramint.2017.05.179

D.S. Tsai and C.C. Chou, Review of the Soft Sparking Issues in Plasma Electrolytic Oxidation, Metals, 2018, 8, p 105. https://doi.org/10.3390/met8020105

N. Xiang, R. Song, C. Wang, Q. Mao, Y. Ge and J. Ding, Formation of Corrosion Resistant Plasma Electrolytic Oxidation Coatings on Aluminum Alloy with Addition of Sodium Tungstate Species, Corrosion Eng. Sci. Technol., 2016, 51, p 146–154. https://doi.org/10.1179/1743278215Y.0000000040

G. Asrat Mengesha, J.P. Chu, B.-S. Lou and J.-W. Lee, Corrosion Performance of Plasma Electrolytic Oxidation Grown Oxide Coating on Pure Aluminum: Effect of Borax Concentration, J. Mater. Res. Technol., 2020, 9(4), p 8766–8779. https://doi.org/10.1016/j.jmrt.2020.06.020

D.S. Tsai, G.-W. Chen and C.-C. Chou, Probe the Micro Arc Softening Phenomenon with Pulse Transient Analysis in Plasma Electrolytic Oxidation, Surf. Coat. Technol., 2019, 357, p 235–243. https://doi.org/10.1016/j.surfcoat.2018.09.080

M. Amiri et al., Investigation of Aluminum Oxide Coatings Created by Electrolytic Plasma Method in Different Potential Regimes, J. Compos. Comp., 2020, 2(4), p 115–122.

F. Simchen et al., Introduction to Plasma Electrolytic Oxidation—An Overview of the Process and Applications, Coatings, 2020, 10(7), p 628. https://doi.org/10.3390/coatings10070628

F. Aydin and A. Ayday, Role of Graphene Additive on Wear and Electrochemical Corrosion Behaviour of Plasma Electrolytic Oxidation (PEO) Coatings on Mg–MWCNT Nanocomposite, Surf. Eng., 2020, 36(8), p 791–799. https://doi.org/10.1080/02670844.2019.1689640

B. Kasalica and M. Petković-Benazzouz, Mechanisms of Plasma Electrolytic Oxidation of Aluminum at the Multi-hour Timescales, Surf. Coat. Technol., 2020, 390, p 125681. https://doi.org/10.1016/j.surfcoat.2020.125681

M.P. Kamil, M. Kaseem and Y.G. Ko, Soft Plasma Electrolysis with Complex Ions for Optimizing Electrochemical Performance, Sci. Rep., 2017, 7, p 44458. https://doi.org/10.1038/srep44458(2017)

Y. Cheng, T. Wang, S. Li, Y. Cheng, J. Cao and H. Xie, The Effects of Anion Deposition and Negative Pulse on the Behaviors of Plasma Electrolytic Oxidation (PEO)da Systematic Study of the PEO of a Zirlo Alloy in Aluminate Electrolytes, Electrochim. Acta, 2017, 225, p 47–68. https://doi.org/10.1016/j.electacta.2016.12.115

L. Shao, H. Li, B. Jiang, C. Liu and X. Gu, A Comparative Study of Corrosion Behavior of Hard Anodized and Micro-Arc Oxidation Coatings on 7050 Aluminum Alloy, Metals, 2018, 8(3), p 165. https://doi.org/10.3390/met8030165

J. Bajat, R. Vasilic, S. Stojadinovic and V. Miskovic-Stankovic, Corrosion Stability of Oxide Coatings Formed by Plasma Electrolytic Oxidation of Aluminum: Optimization of Process Time, Corrosion, 2013, 69, p 693–702. https://doi.org/10.5006/0859

J. Martin, A. Nominé, F. Brochard, J.L. Briançon, C. Noël, T. Belmonte, T. Czerwiec and G. Henrion, Delay in Micro-Discharges Appearance During PEO of Al: Evidence of a Mechanism of Charge Accumulation at the Electrolyte/oxide Interface, Appl. Surf. Sci., 2017, 410, p 29–41. https://doi.org/10.1016/j.apsusc.2017.03.088

J.A. Curran and T.W. Clyne, Porosity in Plasma Electrolytic Oxide Coatings, Acta Mater., 2006, 54, p 1985–1993. https://doi.org/10.1016/j.actamat.2005.12.029

G. Sundararajan and L. Rama, Mechanisms Underlying the Formation of Thick Alumina Coatings Through the MAO Coating Technology, Surf. Coat. Technol., 2003, 167(2–3), p 269–277. https://doi.org/10.1016/S0257-8972(02)00918-0

A.B. Rogov, A. Yerokhin and A. Matthews, The Role of Cathodic Current in Plasma Electrolytic Oxidation of Aluminum: Phenomenological Concepts of the “Soft Sparking” Mode, Langmuir, 2017, 33, p 11059e11069. https://doi.org/10.1021/acs.langmuir.7b02284

P.V. Kumar and B. Shantanu, Plasma Processing of Aluminum Alloys to Promote Adhesion: A Critical Review, Rev. Adhesion Adhesives, 2017, 5(1), p 79–104.

C. Cheng and A.H.W. Ngan, Theoretical Pore Growth Models for Nanoporous Alumina, Nanoporous Alumina, 2015, 2, p 31–60. https://doi.org/10.1007/978-3-319-20334-8_2

V.P. Singh, A. Sil and R. Jayaganthan, Wear of Plasma Sprayed Conventional and Nanostructured Al2O3 and Cr2O3, Based Coat. Trans. Indian. Inst. Met., 2012, 65, p 1–12. https://doi.org/10.1007/s12666-011-0070-0.1

V.M. Dumitrascu, L. Benea and N.L. Simionescu, Evaluation of Sealing Process on the Surface Properties of Nanoporous Aluminum Oxide Layers Electrochemically Growth on 1050 Aluminum Alloys Surface, IOP Conf. Ser. Mater. Sci. Eng., 2018, 374, p 012013. https://doi.org/10.1088/1757-899X/374/1/012013

R.O. Hussein, D.O. Northwood and X. Nie, Processing-Microstructure Relationships in the Plasma Electrolytic Oxidation (PEO) Coating of a Magnesium Alloy, Mater. Sci. Appl., 2014, 5, p 124–139. https://doi.org/10.4236/msa.2014.53017

S.H. Awad and H. Qian, Effect of Cathodic Component of Current on Porosity and Hardness Characteristics of Micro Plasa Oxidation (MPO) Coatings on Aluminum Alloy, Trans. Nonferrous Met. Soc. China, 2005, 15(1), p 113–118.

S. Sharma, T. Nanda and O.P. Pandey, Effect of Particle Size on Dry Sliding Wear Behavior of Sillimanite Reinforced Aluminum Matrix Composites, Cer. Inter., 2018, 44(1), p 104–114. https://doi.org/10.1016/j.ceramint.2017.09.132

T. Wu, C. Blawert and M.L. Zheludkevich, Influence of Secondary Phases of AlSi9Cu3 Alloy on the Plasma Electrolytic Oxidation Coating Formation Process, J. Mat. Sci. Technol., 2020, 50, p 75–85. https://doi.org/10.1016/j.jmst.2019.12.031

H. Duan and C. Yan, Effect of Electrolyte Additives on Performance of Plasma Electrolytic Oxidation Films Formed on Magnesium Alloy AZ91D, Electrochim. Acta, 2007, 52, p 3785–3793. https://doi.org/10.1016/j.electacta.2006.10.066

J.-H. Wang, M.-H. Du, F.-Z. Han and J. Yang, Effects of the Ratio of Anodic and Cathodic Currents on the Characteristics of Micro-Arc Oxidation Ceramic Coatings on Al Alloys, Appl. Surf. Sci., 2014, 292, p 658–664. https://doi.org/10.1016/j.apsusc.2013.12.028

A. Nomine, J. Martin, G. Henrion and T. Belmonte, Effect of Cathodic Micro-Discharges on Oxide Growth during Plasma Electrolytic Oxidation (PEO), Surf. Coat. Technol., 2015, 269, p 131–137. https://doi.org/10.1016/j.surfcoat.2015.01.076

A.B. Rogov and V.R. Shayapov, The Role of Cathodic Current in PEO of Aluminum: Influence of Cationic Electrolyte Composition on the Transient Current-Voltage Curves and the Discharges Optical Emission Spectra, Appl. Surf. Sci., 2017, 394, p 323–332. https://doi.org/10.1016/j.apsusc.2016.10.115

G.A. Mengesha, J.P. Chu, B.S. Lou and J.W. Lee, Effects of Processing Parameters on the Corrosion Performance of Plasma Electrolytic Oxidation Grown Oxide on Commercially Pure Aluminum, Metals., 2020, 10, p 394. https://doi.org/10.3390/met10030394

R. Bahador, N. Hosseinabadi and A. Yaghtin, Microstructural and Mechanical Characterizations of Stir Cast Aluminum 356–Nb2O5 Composite, Adv. Compos. Hybrid. Mater., 2020 https://doi.org/10.1007/s42114-020-00173-1

A. Miftakhova and Y. Chen, Effect of Rolling on the Friction Coefficient in Three-Body Contact, Adv. Mechanic. Eng. (AIME), 2019, 11(8), p 1–9.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Bahador, R., Hosseinabadi, N. & Yaghtin, A. Effect of Power Duty Cycle on Plasma Electrolytic Oxidation of A356-Nb2O5 Metal Matrix Composites. J. of Materi Eng and Perform 30, 2586–2604 (2021). https://doi.org/10.1007/s11665-021-05597-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05597-4