Abstract

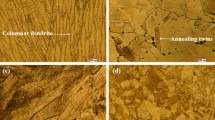

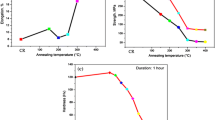

Two-stage rolling process was adopted to study the texture and special grain boundary distribution of C71500 copper-nickel alloy tubes at different annealing temperatures. The effect of temperature on the texture of C71500 copper-nickel alloy tube was analyzed. The hardness analysis was used to study the recrystallization and low lattice reconstruction grain boundaries ratio at different temperatures. It was observed by electron backscattered diffraction that static recovery of the alloy tube occurs when the annealing temperature below 800 °C and it transforms into static recrystallization at 825 °C. The initial strain-induced grain boundary migration temperature of alloy tube is about 775 °C. The number of Copper{112}<111> textures can be used to determine the ratio of the low coincidence site lattice (low ΣCSL) grain boundary. The optimal annealing process for C71500 alloy tube to obtain a high proportion of special grain boundaries is to keep the temperature at 800 °C for 15 min.

Similar content being viewed by others

References

M. Yang and Y.J. Nie, Study on Non-Equilibrium Grain-Boundary Segregation of Sulfur among Hastelloy X, Adv. Mater. Res., 2011, 181-182, p 861–865.

X. Gao, H. Wu, M. Liu, Y. Zhang and F. Gao, Corrosion Behavior of High Strength C71500 Cu-Ni Alloy Pipe in Simulated High Sulfide Polluted Seawater at Different Temperatures, Int. J. Electrochem. Sci., 2021, 16(2), p 150932.

H. Lilong, L.X.M. Pingxiu, L. Ping, L. Wei, C. Xiaohong and H. Daihua, Influence of Cold Drawing Deformation and Annealing on Microstructure and Property of New 70Cu-1Sn Brass, J. Mater. Sci. Eng., 2017, 35(04), p 643–649.

L. Zhou, Q.N. Shi, X.L. Cai and J.L. Wang, Grain Boundary Characteristics Distribution of Ultra-Fine Grained Copper Prepared by Severe Plastic Deformation and Annealing, Cailiao Rechuli Xuebao Trans. Mater. Heat Treat., 2017, 38(6), p 25–30.

S. Ratanaphan, D. Raabe, R. Sarochawikasit, D. L. Olmsted, G. S. Rohrer, K. N. Tu, Grain Boundary Character Distribution in Electroplated Nanotwinned Copper. J. Mater. Sci., 2017, 52, p 4070–4085

J. Ying, F. Xiao-ying, W. You-lin, P. Huan and D. Jia-ze, Grain Boundary Character Distributions of Brass H68 Annealed After Cold Rolling at Different Temperatures, Trans. Mater. Heat Treat., 2014, 01, p 40–44.

B. Oberdorfer, D. Setman, E.-M. Steyskal, A. Hohenwarter, W. Sprengel, M. Zehetbauer, R. Pippan and R. Würschum, Grain Boundary Excess Volume and Defect Annealing of Copper After High-Pressure Torsion, Acta Mater., 2014, 68, p 189–195.

X. Gao, H. Wu, M. Liu, Y. Zhang and X. Zhou, Dynamic Recovery and Recrystallization Behaviors of C71500 Copper-Nickel Alloy Under Hot Deformation, J. Mater. Eng. Perform., 2020, 29(11), p 7678–7692.

X. Gao, H. Wu, M. Liu, Y. Zhang, F. Gao and H. Sun, Processing Map of C71500 Copper-nickel Alloy and Application in Production Practice, J. Wuhan Univ. Technol., 2020, 35(06), p 1104–1115.

X. Gao, H. Wu, D. Tang, D. Li, M. Liu and X. Zhou, Six Different Mathematical Models to Predict the Hot Deformation Behavior of C71500 Cupronickel Alloy, Rare Metal Mater. Eng., 2020, 49(12), p 4129–4141.

G. Yubi, D. Yutian, C. Jianjun, X. Jiayu, M. Yuanjun and W. Xingmao, Effect of Thermo-Mechanical Processing on Grain Boundary Character Distribution of GH3625 Superalloy, Rare Metal Mater. Eng., 2019, 11, p 3585–3592.

S. Sinha, D.I. Kim, E. Fleury and S. Suwas, Effect of Grain Boundary Engineering on the Microstructure and Mechanical Properties of Copper Containing Austenitic Stainless Steel, Mater. Sci. Eng. A, 2015, 626, p 175–185.

X. Gao, H.B. Wu, M. Liu, Y. Zhang, Effect of annealing time on grain boundary characteristics of C71500 cupronickel alloy tubes with different deformation, Mater. Charact., 2020, 169, p 110603

C. Xingpin, C. Dan, S. Hongfu and W. Lixia, Effects of Cold Rolling Reduction and Annealing Temperature on Microstructure and Texture Evolution of Cu-44%Ni Alloy, Rare Metal Mater. Eng., 2018, 47(7), p 1958–1964.

T. Liu, X. Shuang, B. Qin, B. Zhou and T. Shoji, Three-Dimensional Study of Grain Boundary Engineering Effects on Intergranular Stress Corrosion Cracking of 316 Stainless Steel in High Temperature Water, J. Nucl. Mater., 2018, 498, p 290–299.

N.V. Malyar, H. Springer, J. Wichert, G. Dehm and C. Kirchlechner, Synthesis and Mechanical Testing of Grain Boundaries at the Micro and Sub-micro Scale, Mater. Test., 2019, 61(1), p 5–18.

R. Feng, W. Song, H. Li, M. Wang and Y. Qi, The effect of residual stress on Σ3(111) twin boundaries fracture behavior in γ-TiAl with molecular dynamics simulation, Model. Simul. Mater. Sci. Eng., 2019, 28(1), p 015001.

R. Xiang-kun, L. Ting-guang, X.I.A. Shuang, Z. Bang-xin, M. Ai-li and Z. Yu-gui, Effect of Deformation and Heat-Treatment on Grain Boundary Distribution Character of Cupronickel B10 Alloy, Chin. J. Nonferrous Metals, 2013, 8, p 2176–2181.

L.I.U. Tingguang, X.I.A. Shuang, L.I. Hui, Z.H.O.U. Bangxin and C. Wenjue, Effect of Original Grain Size on The Boundary Network on Alloy 690 Treated by Grain Boundary Engineering, Acta Metall. Sin., 2011, 47(7), p 859–864.

V. Randle, Twinning-related grain boundary engineering, Acta Mater., 2004, 52(14), p 4067–4081.

C.V. Kopezky, A.V. Andreeva and G.D. Sukhomlin, Multiple Twinning and Specific Properties of Σ = 3n Boundaries in f.c.c Crystals, Acta Metall. Mater., 1991, 39(7), p 1603–1615.

Z. Qing, X. Shuang, Z. Bangxin, B. Qin, S. Cheng, W. Baoshun and C. Zhigang, Effect of Deformation and Thermomechanical Processing On Grain Boundary Character Distribution of Alloy 825 Tubes, Acta Metall. Sinica, 2015, 12, p 1465–1471.

Y. Hua, Z. Nie, G. Huang, Y. Li, H. Xie, D. Liu, Microstructure, Residual Stress and Corrosion Resistance in Electrodeposited Copper Foils, Chinese Materials Conference, 2017

L. Leyun, Z. Yuehong, C. Dawei, M. Yuehui, Dynamic recrystallization of copper alloy and its effect on Corrosion Behavior, in Annual Meeting of Corrosion Resistant Metal Materials of Chinese Society of Corrosion and Protection, 2006

Acknowledgments

This study was financially supported by Ministry of Industry and Information Technology of the People's Republic of China (TC170A2KN-8) and the National Natural Science Foundation of China (No. 51801149). The authors would like to take this opportunity to express their sincere appreciation to the funds.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

We declare that we have no financial and personal relationships with other people or organizations that can inappropriately influence our work, there is no professional or other personal interest of any nature or kind in any product, service and/or company that could be construed as influencing the position presented in, or the review of, the manuscript entitled.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, X., Wu, Hb., Liu, M. et al. Texture and Special Grain Boundary Distribution of C71500 Copper-Nickel Alloy Tubes at Different Annealing Temperatures. J. of Materi Eng and Perform 30, 2365–2373 (2021). https://doi.org/10.1007/s11665-021-05559-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05559-w