Abstract

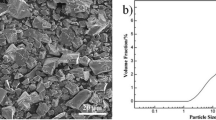

In this work, a 90W-4.9Ni-2.1Fe-3Cu alloy was developed for low-temperature sintering. Conventional 90W-7Ni-3Fe alloy, which is typically manufactured at 1500 °C, was synthesized at the same sintering conditions for comparison. In the low-temperature range from 1250 to 1400 °C, sintering densification, microstructure evolution, and mechanical properties were systematically investigated. For the 90W-4.9Ni-2.1Fe-3Cu alloy, a rapid specimen densification occurs at 1350 °C due to liquid formation over the temperature range from 1328 to 1370 °C. The maximum relative density of 99.01% of the alloy is reached at 1400 °C. According to electron probe microanalysis (EPMA) and transmission electron microscopy (TEM), the alloy is composed of a W phase and a γ-(Ni, Fe, Cu) matrix phase, which is well bonded with W grains. The orientation relationship of these two phases can be described as [001] γ-(Ni, Fe, Cu)∥[\(\bar{1}\)33]W. The tensile strength and hardness of the sintered alloy increase with increasing sintering temperature. At 1400 °C, the tensile strength of the 90W-4.9Ni-2.1Fe-3Cu alloy is with 874 MPa considerably higher than that of the 90W-7Ni-3Fe alloy (385 MPa). The formation mechanism of γ-(Ni, Fe, Cu) phase is included in the discussion.

Similar content being viewed by others

References

R.M. German, P. Suri and S.J. Park, Review: Liquid Phase Sintering, J. Mater. Sci., 2009, 44, p 1–39.

R. Gero, L. Borukhin and I. Pikus, Some Structural Effects of Plastic Deformation on Tungsten Heavy Metal Alloys, Mater. Sci. Eng. A, 2001, 302, p 162–167.

M. Bahgat, M.K. Paek and J.J. Pak, Reduction Investigation of WO3/NiO/Fe2O3 and Synthesis of Nanocrystalline Ternary W–Ni–Fe Alloy, J. Alloys Compd., 2009, 472, p 314–318.

C. Lu, Y. Wang, X. Lei et al., Influence of Fe–W Intermetallic Compound on Fracture Behavior of Steel/Tungsten HIP Diffusion Bonding Joint: Experimental Investigation and First-Principles Calculation, J. Manuf. Process., 2020, 55, p 131–142.

D. Qu, Z. Zhou, J. Tan and J. Aktaa, Characterization of W/Fe Functionally Graded Materials Manufactured by Resistance Sintering Under Ultra-High Pressure, Fusion Eng. Des, 2015, 91, p 21–24.

N. Kang, J.L. Lu, Q.G. Li et al., A New Way to Net-Shaped Synthesis Tungsten Steel by Selective Laser Melting and Hot Isostatic Pressing, Vacuum, 2020, 179, p 109557.

S. Heuer, J. Matĕjček, M. Vilémová et al., Atmospheric Plasma Spraying of Functionally Graded Steel/Tungsten Layers for the First Wall of Future Fusion Reactors, Surf. Coat. Technol, 2019, 366, p 170–178.

W. Zhu, W. Liu, Q. Cai et al., The Study on Low Temperature Sintering of a W–Ni–Cu–Sn Heavy Alloy, Mater. Res. Express, 2018, 6, p 016535.

W. Liu, L. Zhang, Y. Ma et al., Low Temperature Co-sintering of Tungsten Alloy/Steel Composite Structure, Int. J. Refract. Met. Hard Mater., 2020, 90, p 105224.

A. Mondal, A. Upadhyaya and D. Agrawal, Effect of Heating Mode and Sintering Temperature on the Consolidation of 90W–7Ni–3Fe Alloys, J. Alloys Compd., 2011, 509, p 301–310.

H. Liu, S. Cao, J. Zhu et al., Densification, Microstructure and Mechanical Properties of 90W–4Ni–6Mn Heavy Alloy, Int. J. Refract. Met. Hard Mater, 2013, 37, p 121–126.

V.I. Nizhenko and V.V. Skorokhod, Compaction Kinetics with Liquid-Phase Sintering of W–Ni–Sn Pseudoalloys, Powder Metall. Met. Ceram, 2004, 43, p 364–370.

V.I. Nizhenko, V.Y. Petrishchev and V.V. Skorokhod, Effect of Liquid Phase on W-Ni–Sn and W–Co–Sn Pseudoalloys in Liquid–Phase Sintering, Powder Metall. Met. Ceram, 2007, 46, p 105–110.

R.M. German, Lower Sintering Temperature Tungsten Alloys for Space Research, Int. J. Refract. Met. Hard Mater, 2015, 53, p 74–79.

P. Haasen and J.M. Galligan, Physical Metallurgy, Phys. Today, 1978, 31, p 51–52.

A.A. Nayeb-Hashmi and J.B. Clark, Binary Alloy Phase Diagrams, 2nd ed. ASM International, Materials Park, OH, 1991.

E. Abbasi and K. Dehghani, Phase Prediction and Microstructure of Centrifugally Cast Non-equiatomic Co–Cr–Fe–Mn–Ni (Nb, C) High Entropy Alloys, J. Alloys Compd., 2019, 783, p 292–299.

M. Detrois, P.D. Jablonski, S. Antonov et al., Design and Thermomechanical Properties of a γ′ Precipitate-Strengthened Ni-Based Superalloy with High Entropy γ Matrix, J. Alloys Compd., 2019, 792, p 550–560.

M.P. Miles, T.W. Nelson, C. Gunter et al., Predicting Recrystallized Grain Size in Friction Stir Processed 304L Stainless Steel, J. Mater. Sci. Technol., 2019, 35, p 29–36.

R.M. German, Liquid Phase Sintering, Plenum Press, New York, 1985.

W.A. Badawy, K.M. Ismail and A.M. Fathi, Effect of Ni Content on the Corrosion Behavior of Cu–Ni Alloys in Neutral Chloride Solutions, Electrochim. Acta, 2005, 50, p 3603–3608.

R. Haugsrud, T. Norby and P. Kofstad, High-Temperature Oxidation of Cu–30 wt.% Ni–15 wt.% Fe, Corros. Sci., 2001, 43, p 283–299.

H.X. Li, X.J. Hao, G. Zhao et al., Characteristics of the Continuous Coarsening and Discontinuous Coarsening of Spinodally Decomposed Cu–Ni–Fe Alloy, J. Mater. Sci, 2001, 36, p 779–784.

Q. Zhou, J. Jiang, Q. Zhong et al., Preparation of Cu–Ni–Fe Alloy Coating and Its Evaluation on Corrosion Behavior in 3.5% NaCl Solution, J. Alloys Compd., 2013, 563, p 171–175.

H.V.M. Lopez, T. Sakurai, K. Hirano et al., A Study of Phase Decomposition in CuNiFe Alloys, Acta Metall. Mater, 1993, 41, p 265–271.

E.O. Avila-Davila, D.V. Melo-Maximo, V.M. Lopez-Hirata et al., Microstructural Simulation in Spinodally-Decomposed Cu-70 at.% Ni and Cu–46 at.%Ni–4at.% Fe Alloys, Mater. Charact, 2009, 60, p 560–567.

F. Findik, Improvements in Spinodal Alloys from Past to Present, Mater. Des., 2012, 42, p 131–146.

B.H. Xiong, J.A. Wang, Y.C. Chen et al., Spinodal Decomposition of Ni-32.7at%Cu Alloy and Its Effect on Recrystallization Texture, Heat Treatment Metals, 2018, 43, p 53–59.

J. Das, U.R. Kiran, A. Chakraborty et al., Hardness and Tensile Properties of Tungsten Based Heavy Alloys Prepared by Liquid Phase Sintering Technique, Int. J. Refract. Met. Hard Mater, 2009, 27, p 577–583.

D.P. Xiang, L. Ding, Y.Y. Li et al., Microstructure and Mechanical Properties of Fine-Grained W-7Ni-3Fe Heavy Alloy by Spark Plasma Sintering, Mater. Sci. Eng. A, 2012, 551, p 95–99.

K.S. Churn and R.M. German, Fracture Behavior of W-Ni-Fe Heavy Alloys, Metall. Mater. Trans. A, 1984, 15, p 331–338.

R.L. Woodward and R.G. O’Donnell, Tensile Rupture of Tungsten Alloys by the Cascade of Crack Nucleation Events, J. Mater. Sci., 2000, 35, p 4067–4072.

U.R. Kiran et al., Tensile and Impact Behavior of Swaged Tungsten Heavy Alloys Processed by Liquid Phase Sintering, Int. J. Refract. Met. Hard Mater., 2013, 37, p 1–11.

J. Das, G.A. Rao, S.K. Pabi et al., Thermo-Mechanical Processing, Microstructure and Tensile Properties of a Tungsten Heavy Alloy, Mater. Sci. Eng. A, 2014, 613, p 48–59.

Acknowledgments

This work was supported by the National Natural Science Foundation of China (Grant Nos. 51701242, 51931012), and the Natural Science Foundation of Hunan Province of China (Grant No. 2018JJ3648).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, W., Liu, W., Ma, Y. et al. Densification, Microstructure Evolution, and Mechanical Properties of Low-Temperature-Sintered 90W-4.9Ni-2.1Fe-3Cu Alloy. J. of Materi Eng and Perform 30, 2761–2771 (2021). https://doi.org/10.1007/s11665-021-05539-0

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05539-0