Abstract

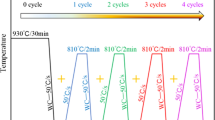

To explore an appropriate intermediate temperature of heat treatment during the cold working of UNS N10003 alloy, the influence of heat treatment temperature, time, the induced deformation, the mechanical properties, and microstructures by the pre-stretching method was investigated systematically. The results showed that after heat treatment (performed at 760 °C, 6 h), the strength was not reduced, and the elongation was not improved efficiently. However, after only 30 min of heat treatment at 870 °C, their strength was efficiently reduced, and their elongation was substantially improved, reaching the original sample level. Moreover, no apparent changes were observed with the extension of heat treatment time. The morphology of the microstructures and fractures indicated that the recovery and recrystallization process occurred at the temperature of 870 °C during the heat treatment, which resulted in the residual stress relieving and microstructural reconstruction. Correspondingly, the fractographs were also transformed from cleavage to ductile. Therefore, the heat treatment during the cold working should be carried out at 870 °C, enhancing energy- and cost-efficient production of UNS N10003 alloy.

Similar content being viewed by others

References

J.H.E. McCoy, Status of Materials Development for Molten Salt Reactors. ORNL(USA), 1978, ORNL-TM-5920. https://doi.org/10.2172/5195742.

M. Wan, Y. Zhao, W. Zeng, R. Ma and H. Bian, Effect of Solution Temperature on Microstructure and Properties of Ti-1300 Alloy, Rare Metal Mater.Eng., 2015, 44, p 1209-1213.

J. Xie, S. Tian and X. Zhou, Effect of Solution Temperature on the Permanent Fracture Mechanism of FGH95 Nickel-based Alloy, Rare Metal Mater. Eng., 2012, 41, p 447-451.

T. Zengwu, L. Jinshan, H. Rui, L. Yi and B. Guanghai, Effects of Solution Heat Treatment on Carbide of Ni-Cr-W Superalloy, Rare Metal Mater. Eng, 2010, 39, p 1157-1161.

K. Yu, X. Shi, Z. Jiang, C. Li, S. Chen, W. Tao, X. Zhou and Z. Li, Effects of Solution Treatment on Grain Coarsening and Hardness of Laser Welds in UNS N10003 Alloy Contained Different Carbon Content, J. Mater. Sci. Technol., 2019, 35, p 1719-1726.

T. Kvackaj, J. Zrnik, V. Vrchovinsky and P. Wangyao, Controlled Rolling of Hastelloy-N, High Temp. Mater. Processes (London), 2011, 21, p 351-360.

D. Xin, Effects of Hot Rolling on the Microstructure and Mechanical Properties of Hastelloy/Steel Composite Panel, Harbin Engineering University, Harbin, 2018.

A.G. Cepolina and D.A. Canonico, Measurement of Residual Stresses, Weld. J., 1971, 50, p 31s-18.

X.Z. Zhu, Effect of Solution Heat Treatment on Microstructure and Properties of UNS N10003 Alloy, Rare Metal Mater Eng, 2016, 45, p 1583-1587.

X.Z. Xiaoyu Zhang, D. Li and S. Guo, Effects of Two-Step Annealing and Initial Grain Size on the Grain Boundary Character Distributions of Hastelloy C-276, J Northeastern Univ (Nat Sci)., 2018, 39, p 631-632.

Z. Li, L. Zhang, N. Sun, Y. Sun and A. Shan, Effects of Prior Deformation and Annealing Process on Microstructure and Annealing Twin Density in a Nickel Based Alloy, Mater. Charact., 2014, 95, p 299-306.

L.L. Shaw, J. Villegas, J.-Y. Huang and S. Chen, Strengthening via Deformation Twinning in a Nickel Alloy, Mater. Sci. Eng. A, 2008, 480, p 75-83.

K.K. Blankenship, Molten salt reactor program. Semiannual Progress Report for period ending July 31, 1964.

Kokomo(MS), Fabrication of Haynes and Hastelloy Solid-Solution Strengthened High-temperature Alloy.http://haynesintl.com/docs/default-source/pdfs/new-alloy-brochures/fabrication-and-welding-brochure.pdf, 2015.

Acknowledgments

This work was supported by Shanghai Natural Science Foundation (Grant Nos. 18ZR1448000 & 19ZR1468200), National Natural Science Foundation of China (Grant No. 51671154), and Strategic Priority Research Program of Chinese Academy of Sciences (Grant Nos. XD02004210 & XDA21080100).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Fan, J., Li, P., Liang, J. et al. Intermediate-Temperature Heat Treatment of UNS N10003 Alloy during Cold Working. J. of Materi Eng and Perform 30, 2355–2364 (2021). https://doi.org/10.1007/s11665-021-05538-1

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05538-1