Abstract

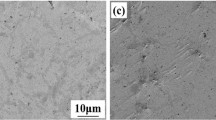

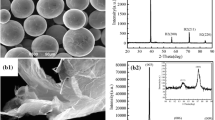

Ti-6Al-4Sn-9Zr-1.21Nb-1.6Mo-0.3Si powders and graphene nanoplatelets (GNPs) were used as the raw materials to prepare GNPs/Ti-Al-Sn-Zr-Nb-Mo-Si composites by using spark plasma sintering method. The effect of adding 1-4 wt.% GNPs on the porosity, hardness, microstructure, phase composition and oxidation resistance of composites at 1073 and 1173 K were investigated. The results show that all GNPs/Ti-Al-Sn-Zr-Nb-Mo-Si composites before oxidation possessed the porosity of not more than 0.20% and the average hardness of higher than 480 HV. The porosity of composites decreased and the average hardness of composites increased, while the content of graphene increased. Compared with the matrix, Ti-6Al-4Sn-9Zr-1.21Nb-1.6Mo-0.3Si-4GNP possessed highest hardness (533.9 HV) and lowest porosity (0.14%). Compared with the composites before oxidation, the hardness of the composites oxidized at 1073 K and 1173K decreased by less than 10%, which meant that the composites still possessed excellent performance at high temperature. GNPs/Ti-Al-Sn-Zr-Nb-Mo-Si composites with adding various graphene oxidized at 1073 K and 1173K were composed of TiO2, Al2O3, SiO2, SnO2, Nb2O5, Ti3O5, ZrO2 and MoO3 and MoSi2 was just generated after oxidation at 1073 K. The GNPs content and oxidation temperature influenced the oxidation resistance. At 1173 K, the composite with 1 wt.% GNPs possessed the lowest average oxidation rate (2.57 × 10−3 g m−2 h−1), which was about 84.7% less than that of the matrix alloy, and its thickness of the oxidized layer was thinnest, which was about 12 μm. The oxidation resistance of the composites with adding 1-4 wt.% GNPs was better than the unreinforced alloy.

Similar content being viewed by others

References

X. Wang, L. Wang, F. Yang, L.S. Luo, H. Yan, X.D. Liu, X.Z. Li, R.R. Chen, Y.Q. Su, J.J. Guo and H.Z. Fu, Hydrogen Induced Microstructure Evolution of Titanium Matrix Composites, Int. J. Hydrogen Energy, 2018, 43, p 9838–9847.

D.D. Zhu, H.T. Xu, D. Dong, Y.M. He, X.H. Wang and Q. He, Brazing of (TiB þ Y2O3) Reinforced Titanium Matrix Composites Using CuTiZrNi Amorphous Filler Alloy, Vacuum, 2020, 174, p 109212.

Q. Shi, Y.Y. Tse and R.L. Higginson, Microstructure Evolution and Microhardness Analysis of Metastable Beta Titanium Alloy Ti-15V-3Cr-3Al-3Sn Consolidated Using Equal-Channel Angular Pressing from Machining Chips, J. Mater. Eng. Perform., 2020, 29, p 4142–4153.

I. Farías, L. Olmos, O. Jiménez, M. Flores, A. Braem and J. Vleugels, Wear Modes in Open Porosity Titanium Matrix Composites with TiC Addition Processed by Spark Plasma Sintering, T. Nonferr. Metal. Soc., 2019, 29, p 1653–1664.

M. Jayaprakash, D.H. Ping and Y. Yamabe-Mitarai, Effect of Zr and Si Addition on High Temperature Mechanical Properties of Near-a Ti-Al-Zr-Sn Based Alloys, Mater. Sci. Eng. A, 2014, 612, p 456–461.

J.J. Dai, J.Y. Zhu, C.Z. Chen and F. Weng, High Temperature Oxidation Behavior and Research Status of Modifications on Improving High Temperature Oxidation Resistance of Titanium Alloys and Titanium Aluminides: A Review, J. Alloys Compd., 2016, 685, p 784–798.

M.D. Hayat, H. Singh, Z. He and P. Cao, Titanium Metal Matrix Composites: An Overview, Compos. Part A, 2019, 121, p 418–438.

K. Vasanthakumar, S. Ghosh, N. Koundinya, S. Ramaprabhu and S.R. Bakshi, Synthesis and Mechanical Properties of TiCx and Ti(C, N) Reinforced Titanium Matrix In Situ Composites by Reactive Spark Plasma Sintering, Mater. Sci. Eng. A, 2019, 759, p 30–39.

A. Azarniya, A. Azarniya, S. Sovizi, H.R.M. Hosseini, T. Varol, A. Kawasaki and S. Ramakrishna, Physicomechanical Properties of Spark Plasma Sintered Carbon Nanotube-Reinforced Metal Matrix Nanocomposites, Prog. Mater. Sci., 2017, 90, p 276–324.

A. Nieto, D. Lahiri and A. Agarwal, Synthesis and Properties of Bulk Graphene Nanoplatelets Consolidated by Spark Plasma Sintering, Carbon, 2012, 50, p 4068–4077.

Y.M. Hunge, A.A. Yadav, A.G. Dhodamani, N. Suzuki, C. Terashima, A. Fujishima and V.L. Mathe, Enhanced Photocatalytic Performance of Ultrasound Treated GO/TiO2 Composite for Photocatalytic Degradation of Salicylic Acid under Sunlight Illumination, Ultrason. Sonochem., 2020, 61, p 104849.

A.A. Yadav, Y.M. Hunge and S. Kang, Spongy Ball-Like Copper Oxide Nanostructure Modified by Reduced Graphene Oxide for Enhanced Photocatalytic Hydrogen Production, Mater. Res. Bull., 2021, 133, p 111026.

A. Choudhari, B.A. Bhanvase, V.K. Saharan, P.H. Salame and Y. Hunge, Sonochemical Preparation and Characterization of rGO/SnO2 Nanocomposite: Electrochemical and Gas Sensing Performance, Ceram. Int., 2020, 46, p 11290–11296.

Y.M. Hunge, A.A. Yadav, S. Khan, K. Takagi, N. Suzuki, K. Teshima, C. Terashima and A. Fujishima, Photocatalytic Degradation of Bisphenol A Using Titanium Dioxide@Nanodiamond Composites under UV Light Illumination, J. Colloid Interf. Sci., 2021, 582, p 1058–1066.

A.A. Yadav, Y.M. Hunge, S.B. Kulkarni, C. Terashima and S. Kang, Three-Dimensional Nanoflower-Like Hierarchical Array of Multifunctional Copper Cobaltate Electrode as Efficient Electrocatalyst for Oxygen Evolution Reaction and Energy Storage Application, J. Colloid Interfaces Sci., 2020, 576, p 476–485.

L.L. Dong, B. Xiao, Y. Liu, Y.L. Li, Y.Q. Fu, Y.Q. Zhao and Y.S. Zhang, Sintering Effect on Microstructural Evolution and Mechanical Properties of Spark Plasma Sintered Ti Matrix Composites Reinforced by Reduced Graphene Oxides, Ceram. Int., 2018, 44, p 17835–17844.

L.L. Dong, B. Xiao, L.H. Jin, J.W. Lu, Y. Liu, Y.Q. Fu, Y.Q. Zhao, G.H. Wu and Y.S. Zhang, Mechanisms of Simultaneously Enhanced Strength and Ductility of Titanium Matrix Composites Reinforced with Nanosheets of Graphene Oxides, Ceram. Int., 2019, 45, p 19370–19379.

J.W. Lu, L.L. Dong, Y. Liu, Y.Q. Fu, W. Zhang, Y. Du, Y.S. Zhang and Y.Q. Zhao, Simultaneously Enhancing the Strength and Ductility in Titanium Matrix Composites via Discontinuous Network Structure, Compos. Part A., 2020, 136, p 105971.

S.S. Chen, L. Brown, M. Levendorf, W.W. Cai, S.Y. Ju, J. Edgeworth, X.S. Li, C.W. Magnuson, A. Velamakanni, R.D. Piner, J.Y. Kang, J. Park and R.S. Ruoff, Oxidation Resistance of Graphene Coated Cu and Cu/Ni Alloy, ACS Nano, 2011, 5, p 1321–1327.

J. Liu, M. Wu, Y. Yang, G. Yang, H. Yan and K. Jiang, Preparation and Mechanical Performance of Graphene Platelet Reinforced Titanium Nanocomposites for High Temperature Applications, J. Alloys Compd., 2018, 765, p 1111–1118.

A. Nieto, A. Kumar, D. Lahiri, C. Zhang, S. Seal and A. Agarwal, Oxidation Behavior of Graphene Nanoplatelet Reinforced Tantalum Carbide Composites in High Temperature Plasma Flow, Carbon, 2014, 67, p 398–408.

Y. Jiao, L.J. Huang and L. Geng, Progress on Discontinuously Reinforced Titanium Matrix Composites, J. Alloys Compd., 2018, 767, p 1196–1215.

S. Tkachenko, J. Cizek, R. Mušálek, K. Dvořák, Z. Spotz, E.B. Montufar, T. Chráska, I. Křupka and L. Čelko, Metal Matrix to Ceramic Matrix Transition via Feedstock Processing of SPS Titanium Composites Alloyed with High Silicone Content, J. Alloys Compd., 2018, 764, p 776–788.

H.C. Cao and Y.L. Liang, The Microstructures and Mechanical Properties of Graphene-Reinforced Titanium Matrix Composites, J. Alloys Compd., 2020, 812, p 152057.

J.B. Hou, F.H. Chi, G.R. Cui, W.Z. Chen and W.C. Zhang, Strengthening Effects of In-Situ Synthetic Nano-TiC Particles on Ti64 Based Nanocomposites through Adding Graphene Nanoplatelets, Vacuum, 2020, 177, p 109431.

Q. Lu, Y.N. Hao, Y.Y. Wang, P.Z. Feng and J.L. Fan, Microstructural Evolution and High-Temperature Oxidation Mechanisms of a Ti-Mo-Si Composite, Corros. Sci., 2019, 161, p 108180.

S.L. Wei, L.J. Huang, X.T. Li, Q. An and L. Geng, Interactive Effects of Cyclic Oxidation and Structural Evolution for Ti-6Al-4V/(TiCþTiB) Alloy Composites at Elevated Temperatures, J. Alloys Compd., 2018, 725, p 164–178.

L.L. Dong, J.W. Lu, Y.Q. Fu, W.T. Huo, Y. Liu, D.D. Li and Y.S. Zhang, Carbonaceous Nanomaterial Reinforced Ti-6Al-4V Matrix Composites: Properties, Interfacial Structures and Strengthening Mechanisms, Carbon, 2020, 164, p 272–286.

C. Volders and P. Reinke, Reaction Pathways in the Oxidation and Pesting of Molybdenum Disilicide MoSi2 Studied with Scanning Tunneling Microscopy and Spectroscopy, Surf. Sci., 2019, 681, p 134–142.

S. Osswald, M. Havel and Y. Gogotsi, Monitoring Oxidation of Multiwalled Carbon Nanotubes by Raman Spectroscopy, J. Raman Spectrosc., 2017, 38, p 728–736.

K. Shirvanimoghaddam, E. Ghasali, A. Pakseresht, S.M.R. Derakhshandeh, M. Alizadeh, T. Ebadzadeh and M. Naebe, Super Hard Carbon Microtubes Derived from Natural Cotton for Development of High Performance Titanium Composites, J. Alloys Compd., 2019, 775, p 601–616.

Acknowledgments

The authors acknowledge the financial support of Natural Science Foundation of Jiangsu Province (Grant Number: BK20181448), National Natural Science Foundation of China (Grant Number: 51901193), State Key Laboratory of Powder Metallurgy (Grant Number: 621011823), Key Research and Development Program of Shaanxi (Grant Number: 2019GY-151, 2019GY-178, 2020GY-251), Science and Technology Plan Project of Weiyang District in Xi’an City (Grant Number: 201905), Xi’an Science and Technology Project (Grant Number: 2020KJRC0141) and Senior Talent Foundation of Jiangsu University (Grant Number: 15JDG150).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

All the authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gao, G., Ru, J., Cheng, J. et al. Microstructure and Oxidation Resistance of Graphene/Ti-Al-Sn-Zr-Nb-Mo-Si Composites Prepared by Spark Plasma Sintering. J. of Materi Eng and Perform 30, 2174–2181 (2021). https://doi.org/10.1007/s11665-021-05531-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05531-8