Abstract

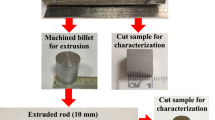

The present study focused on the development of magnesium-based medium entropy alloy (Mg MEA). The multicomponent alloy with a composition, Mg62Li13Zn12Cu10Y3 (at.%), was processed using disintegrated melt deposition technique. The reported medium entropy alloys based on light metals, such as aluminum and magnesium, exhibit very low plasticity, and only cast alloys’ properties were investigated. Currently developed Mg MEA showed an appreciable plasticity of 13.9% in as-cast condition. Secondary processing such as extrusion was applicable on the cast alloy due to its high deformability. A change in intermetallics morphology from continuous pattern in cast alloy to discontinuous pattern in extruded alloy was observed. In line with the change in microstructure, remarkably improved compressive properties were realized in extruded alloy as compared to cast alloy. Compressive strength and plasticity increased from 444 MPa and 13.9% in cast alloy to 675 MPa and 32.7% in extruded alloy. Previously reported lightweight MEAs exhibited a limited plasticity up to 6.5% in the cast form. The current lightweight Mg MEA reached a plasticity of more than twice of cast alloy and more than five times in the case of extruded alloy when compared to reported MEAs’ plasticity in open literature. Unlike reported MEAs, currently developed Mg MEA revealed a relatively simple microstructure with three major phases. From the alloy design perspective, a large atomic size difference (δ: 8.49%) in the alloy was the main cause for the intermetallic formation. However, multiple phase formation was mitigated due to the suitable mixing enthalpy (ΔHmix: − 4.52 kJ/mol). This counterbalancing effect from mixing enthalpy led to a simple microstructure, thereby enhancing the mechanical properties in the currently developed Mg MEA.

Similar content being viewed by others

References

I. Polmear, D. St John, J.F. Nie, and M. Qian, Light Alloys: Metallurgy of the Light Metals, Elsevier Science, Amsterdam, 2017.

B. Cantor, Multicomponent and High Entropy Alloys, Entropy, 2014, 16, p 4749–4768.

B. Cantor, I.T.H. Chang, P. Knight, and A.J.B. Vincent, Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. and Eng. Struct. Mater. Properties Microstruct. Process., 2004, 375, p 213–218.

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6(5), p 299–303.

B.S. Murty, J.-W. Yeh, and S. Ranganathan, High-Entropy Alloys, Butterworth-Heinemann, Oxford, 2014.

K.G. Pradeep, N. Wanderka, P. Choi, J. Banhart, B.S. Murty, and D. Raabe, Atomic-Scale Compositional Characterization of a Nanocrystalline AlCrCuFeNiZn High-Entropy Alloy Using Atom Probe Tomography, Acta Mater., 2013, 61(12), p 4696–4706.

O.N. Senkov, G.B. Wilks, D.B. Miracle, C.P. Chuang, and P.K. Liaw, Refractory High-Entropy Alloys, Intermetallics, 2010, 18(9), p 1758–1765.

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, and Z.P. Lu, Microstructures and Properties of High-Entropy Alloys, Prog. Mater. Sci., 2014, 61, p 1–93.

M. Yao, K. Pradeep, C. Tasan, and D. Raabe, A Novel, Single Phase, Non-equiatomic FeMnNiCoCr High-Entropy Alloy with Exceptional Phase Stability and Tensile Ductility, Scripta Mater., 2014, 72, p 5–8.

Y.F. Ye, Q. Wang, J. Lu, C.T. Liu, and Y. Yang, High-Entropy Alloy: Challenges and Prospects, Mater. Today, 2016, 19(6), p 349–362.

L.J. Santodonato, Y. Zhang, M. Feygenson, C.M. Parish, M.C. Gao, R.J. Weber, J.C. Neuefeind, Z. Tang, and P.K. Liaw, Deviation from High-Entropy Configurations in the Atomic Distributions of a Multi-principal-Element Alloy, Nat. Commun., 2015, 6, p 5964.

M.-H. Tsai and J.-W. Yeh, High-Entropy Alloys: A Critical Review, Mater. Res. Lett., 2014, 2(3), p 107–123.

Z. Li, K.G. Pradeep, Y. Deng, D. Raabe, and C.C. Tasan, Metastable High-Entropy Dual-Phase Alloys Overcome the Strength-Ductility Trade-Off, Nature, 2016, 534(7606), p 227–230.

J.-W. Yeh, Alloy Design Strategies and Future Trends in High-Entropy Alloys, JOM, 2013, 65(12), p 1759–1771.

C.Y. Cheng, Y.C. Yang, Y.Z. Zhong, Y.Y. Chen, T. Hsu, and J.W. Yeh, Physical Metallurgy of Concentrated Solid Solutions from Low-Entropy to High-Entropy Alloys, Curr. Opin. Solid State Mater. Sci., 2017, 21(6), p 299–311.

Y. Ma, F. Yuan, M. Yang, P. Jiang, E. Ma, and X. Wu, Dynamic Shear Deformation of a CrCoNi Medium-Entropy Alloy with Heterogeneous Grain Structures, Acta Mater., 2018, 148, p 407–418.

G. Laplanche, A. Kostka, C. Reinhart, J. Hunfeld, G. Eggeler, and E.P. George, Reasons for the Superior Mechanical Properties of Medium-Entropy CrCoNi Compared to High-Entropy CrMnFeCoNi, Acta Mater., 2017, 128, p 292–303.

J. Pešička, R. Král, S. Daniš, P. Minárik, J. Veselý, V. Šíma, and J. Šmilauerová, Structure and Mechanical Properties of FeAlCrV and FeAlCrMo Medium-Entropy Alloys, Mater. Sci. Eng. A, 2018, 727, p 184–191.

A. Gali and E.P. George, Tensile Properties of High- and Medium-Entropy Alloys, Intermetallics, 2013, 39, p 74–78.

B. Gludovatz, A. Hohenwarter, K.V. Thurston, H. Bei, Z. Wu, E.P. George, and R.O. Ritchie, Exceptional Damage-Tolerance of a Medium-Entropy Alloy CrCoNi at Cryogenic Temperatures, Nat. Commun., 2016, 7, p 10602.

W. Li, P.K. Liaw, and Y. Gao, Fracture Resistance of High Entropy Alloys: A Review, Intermetallics, 2018, 99, p 69–83.

R. Carroll, C. Lee, C.W. Tsai, J.W. Yeh, J. Antonaglia, B.A. Brinkman, M. LeBlanc, X. Xie, S. Chen, P.K. Liaw, and K.A. Dahmen, Experiments and Model for Serration Statistics in Low-Entropy, Medium-Entropy, and High-Entropy Alloys, Sci. Rep., 2015, 5, p 16997.

L. Shao, T. Zhang, L. Li, Y. Zhao, J. Huang, P.K. Liaw, and Y. Zhang, A Low-Cost Lightweight Entropic Alloy with High Strength, J. Mater. Eng. Perform., 2018, 27(12), p 6648–6656.

E.-J. Baek, T.-Y. Ahn, J.-G. Jung, J.-M. Lee, Y.-R. Cho, and K. Euh, Effects of Ultrasonic Melt Treatment and Solution Treatment on the Microstructure and Mechanical Properties of Low-Density Multicomponent Al70Mg10Si10Cu5Zn5 Alloy, J. Alloys Compd., 2017, 696, p 450–459.

J.M. Sanchez, I. Vicario, J. Albizuri, T. Guraya, and E.M. Acuna, Design, Microstructure and Mechanical Properties of Cast Medium Entropy Aluminium Alloys, Sci. Rep., 2019, 9(1), p 6792.

R. Li, J.C. Gao, and K. Fan, Study to Microstructure and Mechanical Properties of Mg Containing High Entropy Alloys, Mater. Sci. Forum, 2010, 650, p 265–271.

X. Yang, S.Y. Chen, J.D. Cotton, and Y. Zhang, Phase Stability of Low-Density, Multiprincipal Component Alloys Containing Aluminum, Magnesium, and Lithium, JOM, 2014, 66(10), p 2009–2020.

F. Otto, Y. Yang, H. Bei, and E.P. George, Relative Effects of Enthalpy and Entropy on the Phase Stability of Equiatomic High-Entropy Alloys, Acta Mater., 2013, 61(7), p 2628–2638.

S. Guo and C.T. Liu, Phase Stability in High Entropy Alloys: Formation of Solid-Solution Phase or Amorphous Phase, Prog. Nat. Sci. Mater. Int., 2011, 21(6), p 433–446.

X. Yang and Y. Zhang, Prediction of High-Entropy Stabilized Solid-Solution in Multi-component Alloys, Mater. Chem. Phys., 2012, 132(2–3), p 233–238.

S. Guo, Q. Hu, C. Ng, and C.T. Liu, More than Entropy in High-Entropy Alloys: Forming Solid Solutions or Amorphous Phase, Intermetallics, 2013, 41, p 96–103.

S. Guo, C. Ng, J. Lu, and C.T. Liu, Effect of valence electron concentration on stability of fcc or bcc phase in high entropy alloys, J. Appl. Phys., 2011, 109, p 103505-1–103505-5.

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw, Solid-Solution Phase Formation Rules for Multi-component Alloys, Adv. Eng. Mater., 2008, 10(6), p 534–538.

C.R. Barbosa, J.O.M.d. Lima, G.M.H. Machado, H.A.M.d. Azevedo, F.S. Rocha, A.S. Barros, and O.F.L.d. Rocha, Relationship Between Aluminum-Rich/Intermetallic Phases and Microhardness of a Horizontally Solidified AlSiMgFe Alloy, Mater. Res., 2018, 22(1), p 1–12.

E. Broitman, Indentation Hardness Measurements at Macro-, Micro-, and Nanoscale: A Critical Overview, Tribol. Lett., 2017, 65(23), p 1–18.

K.S. Tun, T.S. Srivatsan, and M. Gupta, Processing, Microstructure and Mechanical Characterization of MgAlLiZnCaCu high entropy alloy, Processing and Fabrication of Advance Materials XXVII, Jönköping, Sweden, 2019, pp. 27–29 May 2019

M. Gupta and K.S. Tun, Light Weight High Entropy Alloys: Processing Challenges and Properties, Recent Patents on Materials Science, 2017, 10(2), p 116–121.

K.S. Tun and M. Gupta, Microstructural Evolution in MgAlLiZnCaY and MgAlLiZnCaCu Multicomponent High Entropy Alloys, Mater. Sci. Forum, 2018, 928, p 183–187.

G. Cakmak, Effect of Heat Treatment on the Microstructure, Phase Distribution, and Mechanical Properties of AlCoCuFeMnNi High Entropy Alloy, Adv. Mater. Sci. Eng., 2017, 2017, p 1–6.

L.Y. Sheng, F. Yang, T.F. Xi, Y.F. Zheng, and J.T. Guo, Improvement of Compressive Strength and Ductility in NiAl–Cr(Nb)/Dy Alloy by Rapid Solidification and HIP Treatment, Intermetallics, 2012, 27, p 14–20.

Y. Chen, S. Tekumalla, Y.B. Guo, and M. Gupta, Introducing Mg-4Zn-3Gd-1Ca/ZnO Nanocomposite with Compressive Strengths Matching/Exceeding that of Mild Steel, Sci. Rep., 2016, 6, p 32395.

M. Paramsothy, J. Chan, R. Kwok, and M. Gupta, Al2O3 Nanoparticle Addition to Commercial Magnesium Alloys: Multiple Beneficial Effects, Nanomaterials (Basel, Switzerland), 2012, 2(2), p 147–162.

M.F. Horstemeyer, Damage influence on Bauschinger effect of a cast A356 aluminum alloy, Scripta Mater., 1998, 39(11), p 1491–1495.

S.K. Shaha, F. Czerwinski, W. Kasprzak, and D.L. Chen, Tensile and Compressive Deformation Behavior of the Al–Si–Cu–Mg Cast Alloy with Additions of Zr, V and Ti, Mater. Des., 2014, 59, p 352–358.

V. Nesetova and E.Z. Lajtai, Fracture from Compressive Stress Concentrations Around Elastic Flaws, Int. J. Rock Mech. Mining Sci. Geomech. Abstracts, 1973, 10(4), p 265–284.

Acknowledgments

The authors would like to acknowledge Ministry of Education Academic Research Funding, Singapore (WBS# R-265-000-586-114) for the financial support in carrying out this research work.

Author information

Authors and Affiliations

Contributions

KST and MG conceptualized and designed the experiments. KST and VC carried out processing, testing and data collection and analysis. Manuscript preparation was done by KST. MG provided supervision, funding acquisition and manuscript review and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Tun, K.S., Charadva, V. & Gupta, M. Lightweight Medium Entropy Magnesium Alloy with Exceptional Compressive Strength and Ductility Combination. J. of Materi Eng and Perform 30, 2422–2432 (2021). https://doi.org/10.1007/s11665-021-05478-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05478-w