Abstract

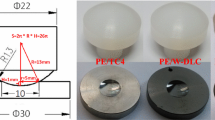

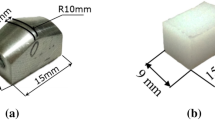

Ball-on-socket articulation is the major structural type of artificial joints. The insight on the mechanical and bio-tribological characteristics of this structure is important for designing both the device itself and its wear assessment regime. Two kinds of ball-on-socket structures were studied including a simplified general model and a real artificial cervical disc. The bio-tribological behaviors were evaluated by in vitro wear simulation method using four kinds of pairs with different combinations of structure, frictional material and testing duration under alternate motion of FE-AR (flexion extension and axial rotation) and LB-AR (lateral bending and axial rotation). In order to analyze the formation mechanism of representative wear characteristics, the mechanical behaviors were also studied by finite element analysis method. The results indicated that there were similar mechanical and bio-tribological characteristics for these two structures after about 9 MC (Million Cycles) tests. Under the axial load, it revealed more serious wear severity in the edge region than that in the central region for both convex polymer component and concave metal component, which may be due to much higher values of equivalent stress and equivalent elastic strain in the edge region than that in the central region. Under FE (flexion extension) or LB (lateral bending) motion, it showed common wide and curved wear grooves with ring distribution in the edge region for both ball component and nucleus pulposus component, which may be attributed to the higher equivalent stress and equivalent elastic strain at the limit position. It just indicated several sliding scratches for TC4 (Ti6Al4V alloy) metal component with an abrasive wear mechanism, while it revealed plastic deformation, surface cracks, sliding scratches and wear grooves for XPE (crosslinking polyethylene) polymer component with a mix of abrasive wear and adhesive wear mechanism. Hence, there was a strong correlation between structural design and bio-tribological characteristics for ball-on-socket prostheses.

Similar content being viewed by others

References

J. Charnley, Low Friction Arthroplasty of the Hip in Rheumatoid Arthritis. SICOT: 168–170, Vienna, 1–7 September, 1963

L. Chawla, S.M. Bandekar, V. Dixit et al., Functional Outcome of Patellar Resurfacing vs Non Resurfacing in Total Knee Arthroplasty in Elderly: A Prospective Five Year Follow-Up Study, J. Arthrosc. Jt. Surg., 2019, 6(1), p 65–69

N.S. Matthews, B.L. Hechler and R. Shah, The Role of Total Joint Replacement Surgery in the Orthognathic Patient, Semin. Orthodont., 2019, 25(3), p 286–293

Su. Chen-Ying, C.-C. Chen, Y.-L. Huang et al., Optimization of Biomolecular Additives for a Reduction of Friction in the Artificial Joint System, Tribol. Int., 2017, 111, p 220–225

S.K. Gupta, A. Chu, A.S. Ranawat et al., Review Article: Osteolysis After Total Knee Arthroplasty, J. Arthroplasty, 2007, 22(6), p 787–799

E. Ingham and J. Fisher, The Role of Macrophages in Osteolysis of Total Joint Replacement, Biomaterials, 2005, 26, p 1271–1286

V. Banchet, V. Fridrici, J.C. Abry et al., Wear and Friction Characterization of Materials for Hip Prosthesis, Wear, 2007, 263, p 1066–1071

M.T. Manley and K. Sutton, Bearings of the Future for Total Hip Arthroplasty, J. Arthroplasty, 2008, 23(7), p 47–50

R. Sonntag, J. Reinders and J.P. Kretzer, What’s next? Alternative Materials for Articulation in Total Joint Replacement, Acta Biomater., 2012, 8, p 2434–2441

E.M.B. del Prever, E. Bistolfi, I. Bracco et al., UHMWPE for Arthroplasty: Past or Future?, J. Orthopaed. Traumatol., 2009, 10, p 1–8

R. Karpiński, Ł. Jaworski, M. Szala, et al. Influence of patient position and implant material on the stress distribution in an artificial intervertebral disc of the lumbar vertebrae. In II International Conference of Computational Methods in Engineering Science (CMES’17), 2017, 15, 07006

H. Liang, B. Shi, A. Fairchild et al., Applications of Plasma Coatings in Artificial Joints: An Overview, Vacuum, 2004, 73, p 317–326

H. Koseki, H. Shindo, K. Baba et al., Surface-Engineered Metal-on-Metal Bearings Improve the Friction and Wear Properties of Local Area Contact in Total Joint Arthroplasty, Surf. Coat. Technol., 2008, 202, p 4775–4779

T.R. Rautray, R. Narayanan and K.H. Kim, Ion Implantation of Titanium Based Biomaterials, Progress Mater. Sci., 2011, 56, p 1137–1177

A.P. Carapeto, A.P. Serro, B.M.F. Nunes et al., Characterization of Two DLC Coatings for Joint Prosthesis: The Role of Albumin on the Tribological Behavior, Surf. Coat. Technol., 2010, 204, p 3451–3458

S. Affatato, M. Spinelli, M. Zavalloni et al., Tribology and Total Hip Joint Replacement: Current Concepts in Mechanical Simulation, Med. Eng. Phys., 2008, 30, p 1305–1317

A. Buford and T. Goswami, Review of Wear Mechanisms in Hip Implants: Paper I-General, Mater. Des., 2004, 25, p 385–393

R.H.M.A. Bartels, R.D. Donk, P. Pavlov et al., Comparison of Biomechanical Properties of Cervical Artificial Disc Prosthesis: A Review, Clin. Neurol. Neurosurg., 2008, 110, p 963–967

F.E. Kennedy, K. Wongseedakaew, D.J. McHugh et al., Tribological Conditions in Mobile Bearing Total Knee Prostheses, Tribol. Int., 2013, 63, p 78–88

S. Wang, J. Song, Z. Liao, P. Feng and W. Liu, Comparison of Wear Behaviors for Artificial Cervical Disc under Flexion/Extension and Axial Rotation Motions, Mater. Sci. Eng. C, 2016, 63, p 256–265

S. Wang, J. Li, Lu. Junzhe, R. Tyagi, Z. Liao, P. Feng and W. Liu, Studies on the Biotribological and Biological Behavior of Thermally Oxidized Ti6Al4V for Use in Artificial Cervical Disc, J. Mater. Eng. Perform., 2017, 26(5), p 2271–2284

S. Wang, Z. Liao, Lu. Junzhe, P. Feng and W. Liu, The Biotribological Behavior of an Artificial Cervical Disc Model with Ball-on-Socket Contact Type under Different Material Configurations, Tribol. Lett., 2017, 65(1), p 8

J. Song, D. Xiang, S. Wang et al., In Vitro Wear Study of PEEK and CFRPEEK Against UHMWPE for Artificial Cervical Disc Application, Tribol. Int., 2018, 122, p 218–227

Pu. Liu Weiqiang, T.G. Hongsheng et al., Geometric Parameter Analysis of Chinese Cervical Discs, J. Tsinghua Univ. (Sci&Technol), 2014, 54(2), p 172–177

D. Cobian, B. Heiderscheit, N. Daehn et al., Comparison of Daily Motion of the Cervical and Lumbar Spine to ASTM F2423-11 and ISO 18192–1, 2011 Standard Testing, J. ASTM Int., 2011, 9(1), p 1–10

D. Xiong, Y. Yang and Y. Deng, Bio-Tribological Properties of UHMWPE Against Surface Modified Titanium Alloy, Surf. Coat. Technol., 2013, 228(S1), p S442–S445

M. Guezmil, W. Bensalah and S. Mezlini, Tribological Behavior of UHMWPE Against TiAl6V4 and CoCr28Mo Alloys under Dry and Lubricated Conditions, J. Mech. Behav. Biomed. Mater., 2016, 63, p 375–385

M.N. Rahaman, A. Yao, B.S. Bal et al., Ceramics for Prosthetic Hip and Knee Joint Replacement, J. Am. Ceram. Soc., 2007, 90(7), p 1965–1988

R. Vicars, P.J. Hyde, T.D. Brown et al., The Effect of Anterior–Posterior Shear Load on the Wear of ProDisc-L TDR, Eur. Spine J., 2010, 19, p 1356–1362

H. Xin, D.E.T. Shepherd and K.D. Dearn, A Tribological Assessment of a PEEK Based Self-Mating Total Cervical Disc Replacement, Wear, 2013, 303, p 473–479

P. Hyde, R. Vicars, J. Fisher et al., Wear Simulation of Total Disc Arthroplasties: Sensitivity to Device Design and Test Parameters, J. ASTM Int., 2012, 9(2), p 1–10

Acknowledgment

This project was supported by the National Natural Science Foundation of China (Grant No. 51705336), the Innovation Commission of Science and Technology of Shenzhen Municipality (Grant No. JCYJ20190807144001746, Grant No. JSGG20191129114422849) and the Shenzhen Municipal Industrial and Information Technology Bureau (Grant No. 20180309163834680).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, S., Xiang, D., Song, J. et al. Insight on the Mechanical and Tribological Characteristics of Ball-on-Socket Artificial Disc under Alternate Motion of Flexion Extension–Axial Rotation and Lateral Bending–Axial Rotation. J. of Materi Eng and Perform 30, 2021–2035 (2021). https://doi.org/10.1007/s11665-021-05472-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05472-2