Abstract

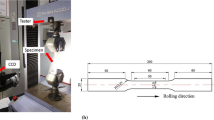

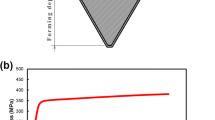

In this article, formability of aluminum alloy AA5083-sheet in single point incremental forming (SPIF) is investigated through forming limit curves (FLCs) and maximum formable wall angle considering different forming parameters and conditions. Theoretical FLCs were predicted for SPIF and conventional forming utilizing deformation instability and Marciniak-Kuczynski methods, respectively, and validated by experiments. SPIF was found to give better formability compared to the conventional one in terms of the limit strain values from varying plane strain to equi-biaxial stretching modes of deformations. Groove depth at the onset of fracture in incremental sheet forming test was observed to be more for higher forming speed, i.e., at higher tool rotational speed and feed and for lower incremental depth. The maximum formable wall angle was improved for lower step depth but not significantly increased for higher forming speed. The forming limit strains and maximum forming wall angle were found to increase for incremental forming at elevated temperature. Microstructure studies revealed grain refinement in the deformed sheet in SPIF forming, and microhardness values in the deformed sheets were observed to increase for incrementally formed parts compared to that of the as-received sheet.

Similar content being viewed by others

Abbreviations

- \(\sigma_{\phi }^{X}\) :

-

Meridional stress in zone X (MPa)

- \(\sigma_{\theta }^{X}\) :

-

Circumferential stress in zone X (MPa)

- \(\sigma_{t}^{X}\) :

-

Thickness stress in zone X (MPa)

- \(\varepsilon_{\phi }^{X}\) :

-

Meridional strain in zone X

- \(\varepsilon_{\theta }^{X}\) :

-

Circumferential strain in zone X

- \(\varepsilon_{t}^{X}\) :

-

Thickness strain in zone X

- \(F_{\phi }^{X}\) :

-

Meridional force in zone X (N)

- \(F_{\theta }^{X}\) :

-

Circumferential force in zone X (N)

- \(F_{t}^{X}\) :

-

Thickness force in zone X (N)

- \(\alpha\) :

-

Meridional angle (radian)

- \(\beta\) :

-

Forming/wall angle (radian)

- \(\theta_{0}\) :

-

Circumferential contact angle (radian)

- \(r_{\text{t}}\) :

-

Tool radius (mm)

- \(r\) :

-

Distance to tool center (mm)

- \(t_{0}\) :

-

Initial sheet thickness (mm)

- \(t\) :

-

Instantaneous sheet thickness (mm)

- \(A_{\text{t}}\) :

-

Transition area between CZ & NZ (mm2)

- \(\bar{\sigma }\) :

-

Equivalent stress (MPa)

- \(\bar{\varepsilon }\) :

-

Equivalent strain

- \(N\) :

-

Tool rotational speed (rpm)

- \(f_{t}\) :

-

Feed rate of tool (mm/min)

- \(\Delta z\) :

-

Incremental step depth (mm)

- \(k\) :

-

Strength coefficient

- \(n\) :

-

Strain hardening exponent

- \(\varepsilon_{0}\) :

-

Prestrain

- \(a\) :

-

Material parameter in Hosford 79’s yield criterion

- \(R\) :

-

Anisotropy coefficient

- \(r_{0}\) :

-

Anisotropy coefficient at 0º to RD

- \(r_{45}\) :

-

Anisotropy coefficient at 45º to RD

- \(r_{90}\) :

-

Anisotropy coefficient at 90º to RD

- \(\theta_{0}^{\prime }\) :

-

Initial groove angle

- \(f_{0}\) :

-

Initial imperfection factor

- \(f\) :

-

Imperfection factor

- \(t_{0}^{Y}\) :

-

Initial sheet thickness in zone Y (mm)

- \(\sigma_{nn}^{X}\) :

-

Stress component in n direction for groove coordinate of zone X

- \(\sigma_{nt}^{X}\) :

-

Stress component in t direction for groove coordinate of zone X

- \(\sigma_{nn}^{Y}\) :

-

Stress component in t direction for groove coordinate of zone Y

- \(\sigma_{nt}^{Y}\) :

-

Stress component in t direction for groove coordinate of zone Y

- \(\sigma_{1}^{Y}\) :

-

Stress in rolling direction in zone Y (MPa)

- \(\sigma_{2}^{Y}\) :

-

Stress in transverse direction in zone Y (MPa)

- \(F_{nn}^{X}\) :

-

Normal force per unit width in zone X (N/mm)

- \(F_{nt}^{X}\) :

-

Shear force per unit width in zone X (N/mm)

- \(F_{nn}^{Y}\) :

-

Normal force per unit width in zone Y (N/mm)

- \(F_{nt}^{Y}\) :

-

Shear force per unit width in zone Y (N/mm)

- \(\varepsilon_{1}\) :

-

Major strain

- \(\varepsilon_{2}\) :

-

Minor strain

- \(\sigma_{1}^{Y}\) :

-

Stress in rolling direction in zone Y (MPa)

- \(d\varepsilon_{nn}^{X}\) :

-

Strain increment in n direction for groove coordinate of zone X

- \(d\varepsilon_{nn}^{Y}\) :

-

Strain increment in n direction for groove coordinate of zone Y

- \(d\varepsilon_{tt}^{X}\) :

-

Strain increment in t direction for groove coordinate of zone Y

- \(d\varepsilon_{tt}^{Y}\) :

-

Strain increment in t direction for groove coordinate of zone Y

- \(d\varepsilon_{nt}^{X}\) :

-

Shear strain increment for groove coordinate of zone X

- \(d\varepsilon_{nt}^{Y}\) :

-

Shear strain increment for groove coordinate of zone Y

- \(d\bar{\varepsilon }^{Y}\) :

-

Equivalent strain increment in zone Y

- \(\varepsilon_{3}^{X}\) :

-

Thickness strain in zone Y

- \(\varepsilon_{3}^{Y}\) :

-

Thickness strain in zone Y

- \(z_{\text{d}}\) :

-

Deformation depth (mm)

- \(z_{\text{f}}\) :

-

Fracture depth (mm)

- \(t_{\text{f}}\) :

-

Final deformed sheet thickness (mm)

References

A.K. Behera, R.A. de Sousa, G. Ingarao, and V. Oleksik, Single Point Incremental Forming: An Assessment of the Progress and Technology Trends from 2005 to 2015, J. Manuf. Process., 2017, 27, p 37–62

T. McAnulty, J. Jeswiet, and M. Doolan, Formability in Single Point Incremental Forming: A Comparative Analysis of the State of the Art, CIRP J. Manuf. Sci. Technol., 2017, 16, p 43–54

M. Janbakhsh, F. Djavanroodi, and M.A. Riahi, Comparative Study on Determination of Forming Limit Diagrams for Industrial Aluminium Sheet Alloys Considering Combined Effect of Strain Path, Anisotropy and Yield Locus, J. Strain Anal. Eng. Des., 2012, 47(6), p 350–361

C. Zhang, L. Leotoing, D. Guines, and E. Ragneau, Theoretical and Numerical Study of Strain Rate Influence on AA5083 Formability, J. Mater. Process. Technol., 2009, 209(8), p 3849–3858

F. Zhalehfar, S.J. Hosseinipour, S. Nourouzi, and A.H. Gorji, A Different Approach for Considering the Effect of Non-Proportional Loading Path on the Forming Limit Diagram of AA5083, Mater. Des., 2013, 50, p 165–173

A. Van Bael, P. Eyckens, S. He, C. Bouffioux, C. Henrard, A.M. Habraken, J. Duflou, and P. Van Houtte, Forming Limit Predictions for Single-Point Incremental Sheet Metal Forming, AIP Conf. Proc., 2007, 907, p 309–314

M. Ham and J. Jeswiet, Forming Limit Curves in Single Point Incremental Forming, CIRP Ann. Manuf. Technol., 2007, 56(1), p 277–280

G. Hussain, L. Gao, N. Hayat, and X. Ziran, A New Formability Indicator in Single Point Incremental Forming, J. Mater. Process. Technol., 2009, 209(9), p 4237–4242

P.A.F. Martins, N. Bay, M. Skjoedt, and M.B. Silva, Theory of Single Point Incremental Forming, CIRP Ann. Manuf. Technol., 2008, 57(1), p 247–252

R. Malhotra, L. Xue, T. Belytschko, and J. Cao, Mechanics of Fracture in Single Point Incremental Forming, J. Mater. Process. Technol., 2012, 212(7), p 1573–1590

Y. Fang, B. Lu, J. Chen, D.K. Xu, and H. Ou, Analytical and Experimental Investigations on Deformation Mechanism and Fracture Behavior in Single Point Incremental Forming, J. Mater. Process. Technol., 2014, 214, p 1503–1515

S. Ai, B. Lu, J. Chen, H. Long, and H. Ou, Evaluation of Deformation Stability and Fracture Mechanism in Incremental Sheet Forming, Int. J. Mech. Sci., 2017, 124–125, p 174–184

M. Durante, A. Formisano, and A. Langella, Observations on the Influence of Tool-sheet Contact Conditions on an Incremental Forming Process, J. Mater. Eng. Perform., 2011, 20, p 941–946

V.C. Do, Q.T. Pham, and Y.S. Kim, Identification of Forming Limit Curve at Fracture in Incremental Sheet Forming, Int. J. Adv. Manuf. Technol., 2017, 92(9–12), p 4445–4455

A. Mulay, S. Ben, S. Ismail, and A. Kocanda, Experimental Investigations into the Effects of SPIF Forming Conditions on Surface Roughness and Formability by Design of Experiments, J. Brazilian Soc. Mech. Sci. Eng., 2017, 39(10), p 3997–4010

V.K. Barnwal, S. Chakrabarty, A. Tewari, K. Narasimhan, and S.K. Mishra, Influence of Single-Point Incremental Force Process Parameters on Forming Characteristics and Microstructure Evolution of AA-6061 Alloy Sheet, J. Mater. Eng. Perform., 2019, 28, p 7141–7154

A. Kumar, V. Gulati, P. Kumar, V. Singh, B. Kumar, and H. Singh, Parametric Effects on Formability of AA2024-O Aluminum Alloy Sheets in Single Point Incremental Forming, J. Mater. Res. Technol., 2019, 8(1), p 1461–1469

K. Maji and G. Kumar, Inverse Analysis and Multi-Objective Optimization of Single-Point Incremental Forming of AA5083 Aluminum Alloy Sheet, Soft. Comput., 2020, 24(6), p 4505–4521

K. Maji, D.K. Pratihar, and S. Patra, Modelling of Electrical Discharge Machining Process Using Regression Analysis, Adaptive Neuro-Fuzzy Inference System and Genetic Algorithm, Int. J. Data Min. model. Manag., 2010, 2(10), p 75–94

A. Kumar and K. Maji, Selection of Process Parameters for Near-Net Shape Deposition in Wire Arc Additive Manufacturing by Genetic Algorithm, J. Mater. Eng. Perform., 2020, 29, p 3334–3352

K. Hamilton and J. Jeswiet, Single Point Incremental Forming at High Feed Rates and Rotational Speeds: Surface and Structural Consequences, CIRP Ann. Manuf. Technol., 2010, 59(1), p 311–314

P. Gupta and J. Jeswiet, Effect of Temperatures During Single Point Incremental Forming, Int. J. Adv. Manuf. Technol., 2018, 95, p 3693–3706

H. Khalatbari, A. Iqbal, X. Shi, L. Gao, G. Hussain, and M. Hashemipour, High-Speed Incremental Forming Process: A Trade-Off Between Formability and Time Efficiency, Mater. Manuf. Process., 2015, 30(11), p 1354–1363

A. Mulay, B.S. Ben, S. Ismail, A. Kocanda, and C. Jasiński, Performance Evaluation of High-Speed Incremental Sheet Forming Technology for AA5754 H22 Aluminum and DC04 Steel Sheets, Arch. Civil Mech. Eng., 2018, 18(4), p 1275–1287

P. Shrivastava and P. Tandon, Microstructure and Texture Based Analysis of Forming Behavior and Deformation Mechanism of AA1050 Sheet During Single Point Incremental Forming, J. Mater. Process. Technol., 2019, 266, p 292–310

M.A. Kulas, P.E. Krajewski, J.R. Bradley, and E.M. Taleff, Forming-Limit Diagrams for Hot-Forming of AA5083 Aluminum Sheet: Continuously Cast Material, J. Mater. Eng. Perform., 2007, 16, p 308–313

P.F. Bariani, S. Bruschi, A. Ghiotti, and F. Michieletto, Hot Stamping of AA5083 Aluminium Alloy Sheets, CIRP-Ann. Manuf. Technol., 2013, 62, p 251–254

J.D. Bressan, S. Bruschi, and A. Ghiotti, Prediction of Limit Strains in Hot Forming of Aluminium Alloy Sheets, Int. J. Mech. Sci., 2016, 115–116, p 702–710

Z. Liu, Heat-Assisted Incremental Sheet Forming: A State-of-the-Art Review, Int. J. Adv. Manuf. Technol., 2018, 98(9–12), p 2987–3003

P. Shrivastava, P. Kumar, P. Tandon, and A. Pesin, Improvement in Formability and Geometrical Accuracy of Incrementally Formed AA1050 Sheets by Microstructure and Texture Reformation Through Preheating, and their FEA and Experimental Validation, J. Braz. Soc. Mech. Sci. Eng., 2018, 40(7), p 1–15

P. Shrivastava and P. Tandon, Effect of Preheated Microstructure Vis-A`-vis Process Parameters and Characterization of Orange Peel in Incremental Forming of AA1050 Sheets, J. Mater. Eng. Perform., 2019, 28, p 2530–2542

Z. Marciniak and K. Kuczynski, Limit strains in the processes of stretch-forming sheet metal, Int. J. Mech. Sci., 1967, 9, p 609–620

M. Ganjiani and A. Assempour, Implementation of a Robust Algorithm for Prediction of Forming Limit Diagrams, J. Mater. Eng. Perform., 2008, 17, p 1–6

D. Banabic, Sheet Metal Forming Processes: Constitutive Modelling and Numerical Simulation, Springer, Berlin, 2010

Z. Kai-feng and Y. Hong-hua, Deformation Behavior of Fine-grained 5083 Al alloy at Elevated Temperature, Trans. Nonferrous Met. Soc. China, 2009, 19, p 307–311

J.M. Allwood, D.R. Shouler, and A.E. Tekkaya, The Increased Forming Limits of Incremental Sheet Forming Processes, Key Eng. Mater., 2007, 344, p 621–628

J.M. Allwood and D.R. Shouler, Generalised Forming Limit Diagrams Showing Increased Forming Limits with Non-planar Stress States, Int. J. Plast., 2009, 25, p 1207–1230

M.K.M. Nor, and I.M. Suhaimi, Effects of Temperature and Strain Rate on Commercial Aluminum Alloy AA5083, Appl Mech Mater., 2014, ISSN: 1662-7482, 660, p 332-336.

H. Ait-Amokhtar, C. Fressengeas, and K. Bouabdallah, On the Effects of the Mg Content on the Critical Strain for the Jerky Flow of Al-Mg Alloys, Mater. Sci. Eng. A, 2015, 631, p 209–213

Acknowledgments

The authors are thankful and gratefully acknowledge the financial support of DST-SERB, India from the Project ECR/2016/001134.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Kumar, G., Maji, K. Investigations into Enhanced Formability of AA5083 Aluminum Alloy Sheet in Single-Point Incremental Forming. J. of Materi Eng and Perform 30, 1289–1305 (2021). https://doi.org/10.1007/s11665-021-05455-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-021-05455-3