Abstract

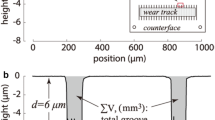

High wear is the primary failure mechanism of Inconel 625 in mechanical parts. The surface modification is workable method to improve tribological performance of Inconel 625. In this paper, the groove-textured surfaces with different widths and pitches were prepared on the surfaces of Inconel 625 by electrical discharge machining technology. The Sn-Ag-Cu solid lubricant was deposited on the grooves. The synergistic effects of Sn-Ag-Cu solid lubricant and groove-textured surface on the tribological performance of Inconel 625 were studied. Results show that the groove-textured surface of Inconel 625 filled with Sn-Ag-Cu solid lubricant shows the lowest friction. Compared with the untextured sample, the friction coefficients of groove-textured sample with the groove density of 20% and the groove-textured sample with the groove density of 25% filled by Sn-Ag-Cu are reduced 35% and 48%, respectively. The textures can trap wear debris under the dry sliding condition. In addition, Sn-Ag-Cu alloys filled in the grooves supply the sufficient lubricant at the contact interface during the sliding process. The lubricating film on the contact surface is formed gradually, which is mainly due to the shear adaptability and low melting point of Sn-Ag-Cu alloy. It shows that deposition of Sn-Ag-Cu solid lubricant coating on the groove-textured surface is an effective way for improving the friction and wear performance of Inconel 625.

Similar content being viewed by others

References

S.K. Rai, A. Kumar, V. Shankar, T. Jayakumar, K.B.S. Rao, and B. Raj, Characterization of Microstructures in Inconel 625 Using X-ray Diffraction Peak Broadening and Lattice Parameter Measurements, Scr. Mater., 2004, 51(1), p 59–63

V. Shankar, K.B.S. Rao, and S.L. Mannan, Microstructure and Mechanical Properties of Inconel 625 Superalloy, J. Nucl. Mater., 2001, 288, p 222–232

G.P. Dinda, A.K. Dasgupta, and J. Mazumder, Laser Aided Direct Metal Deposition of Inconel 625 Superalloy: Microstructural Evolution and Thermal Stability, Mater. Sci. Eng. A, 2009, 509(1–2), p 98–104

M. Nakada, Trends in Engine Technology and Tribology, Tribol. Int., 1994, 27, p 3–8

I. Etsion, State of the Art in Laser Surface Texturing, J. Tribol-T ASME, 2005, 127, p 248–253

X.L. Wang, K. Adachi, K. Otsuka, and K. Kato, Optimization of the Surface Texture for Silicon Carbide Sliding in Water, Appl. Surf. Sci., 2006, 253, p 1282–1286

S. Amini, H.N. Hosseinabadi, and S.A. Sajjady, Experimental Study on Effect of Micro Textured Surfaces Generated by Ultrasonic Vibration Assisted Face Turning on Friction and Wear Performance, Appl. Surf. Sci., 2016, 390, p 633–648

Y. Xu, Z.P. Li, G.Q. Zhang, G. Wang, Z.X. Zeng, C.T. Wang, C.C. Wang, S.C. Zhao, Y.D. Zhang, and T.H. Ren, Electrochemical Corrosion and Anisotropic Tribological Properties of Bioinspired Hierarchical Morphologies on Ti-6Al-4 V Fabricated by Laser Texturing, Tribol. Int., 2019, 134, p 352–364

L. Liang, J. Yuan, X. Li, F. Yang, and L. Jiang, Wear Behavior of the Micro-grooved Texture on WC-Ni3Al Cermet Prepared by Laser Surface Texturing, Int. J. Refract. Met. Hard Mater., 2018, 72, p 211–222

K. Li, Z. Yao, Y. Hu, and W. Gu, Friction and Wear Performance of Laser Peen Textured Surface Under Starved Lubrication, Tribol. Int., 2014, 77, p 97–105

W. Tang, Y. Zhou, H. Zhu, and H. Yang, The Effect of Surface Texturing on Reducing the Friction and Wear of Steel Under Lubricated Sliding Contact, Appl. Surf. Sci., 2013, 273, p 199–204

K. Miyoshi, Solid lubricants and coatings for extreme environments: state of the art survey. Cleveland, Ohio: National Aeronautics and Space Administration, NASA/TM-2007-214668.

J. Oksanen, T.J. Hakala, S. Tervakangas, P. Laakso, L. Kilpi, H. Ronkainen, and J. Koskinen, Tribological Properties of Laser-Textured and ta-C Coated Surfaces with Burnished WS2 at Elevated Temperatures, Tribol. Int., 2014, 70, p 94–103

L. Rapoport, A. Moshkovich, V. Perfilyev, I. Lapsker, G. Halprien, Y. Itovich, and I. Etiosn, Friction and Wear of MoS2 Films on Laser Textured Steel Surfaces, Surf. Coat. Technol., 2008, 202(14), p 3332–3340

D. He, S. Zheng, J. Pu, G. Zhang, and L. Hu, Improving Tribological Properties of Titanium Alloys by Combining Laser Surface Texturing and diamond-Like Carbon Film, Tribol. Int., 2015, 82, p 20–27

D.W. Wang, J.L. Mo, Z.Y. Zhu, H. Ouyang, M.H. Zhu, and Z.R. Zhou, Debris Trapping and Space-Varying Contact Via Surface Texturing for Enhanced Noise Performance, Wear, 2018, 396–397, p 86–97

D. Segu, J. Kim, S. Choi, Y.S. Jung, and S.S. Kim, Application of Taguchi Techniques to Study Friction and Wear Properties of MoS2 Coatings Deposited on Laser Textured Surface, Surf. Coat. Tech., 2013, 232(10), p 504–514

Z. Wu, Y.Q. Xing, P. Huang, and L. Liu, Tribological Properties of Dimple–Textured Titanium Alloys Under Dry Sliding Contact, Surf. Coat Technol., 2017, 309, p 21–28

Y. Lian, C. Mu, L. Wang, B. Yao, J. Deng, and S. Lei, Numerical Simulation and Experimental Investigation on Friction and Wear Behaviour of Micro-textured Cemented Carbide in Dry Sliding Against TC4 Titanium Alloy Balls, Int. J. Refract. Met. Hard Mater., 2018, 73, p 121–131

S. Yan, Q. Ling, H. Rui, and Z. Liu, A Novel Inward Gradient Self-Lubrication Layer with Soft Alloys and Its Lubricating Mechanism, Adv. Mater. Sci. Eng., 2016, 5, p 1–7

L. Rapoport, A. Moshkovich, V. Perfilyev, A. Gedanken, Yu Koltypin, E. Sominski, G. Halperin, and I. Etsion, Wear Life and Adhesion of Solid Lubricant Films on Laser-Textured Steel Surfaces, Wear, 2009, 267, p 1203–1207

J.L. Li, Y. He, D.S. Xiong, Y.K. Qin, J.J. Chen, and H.G. Zhu, Tribological Properties of Silver Coatings with Laser Surface Textured Nickel as Interlayer, Tribol. Int., 2016, 100, p 178–185

P. Koshy and J. Tovey, Performance of Electrical Discharge Textured Cutting Tools, CIRP Ann. Manuf. Technol., 2011, 60, p 153–156

Y. Wan and D. Xiong, The Effect of Laser Surface Texturing on Frictional Performance of Face Seal, J. Mater. Process. Technol., 2008, 197, p 96–100

T. Hu, Y. Zhang, and L. Hu, Tribological Investigation of MoS2 Coatings Deposited on the Laser Textured Surface, Wear, 2012, 278–279, p 77–82

T.E. Abioye, J. Folkes, and A.T. Clare, A parametric Study of Inconel 625 Wire Laser Deposition, J. Mater. Process. Technol., 2013, 213(12), p 2145–2151

G. Marchese, M. Lorusso, S. Parizia, E. Bassini, J.W. Lee, F. Calignano, D. Manfredi, M. Terner, H.U. Hong, D. Ugues, M. Lombardi, and S. Biamino, Influence of Heat Treatments on Microstructure Evolution and Mechanical Properties of Inconel 625 Processed by Laser Powder Bed Fusion, Mater. Sci. Eng. A, 2018, 729, p 64–75

Acknowledgment

This work was supported by the Fundamental Research Funds for Central Universities (2019-YB-20); the Project for Science and Technology Plan of Henan Province (No. 192102210054) and cultivation project for High-value Intellectual Property of Hubei Intellectual Property Bureau (No. 2019-45). Authors also wish to thank the Material Research and Test Center of WUT, and M.J. Yang, X.L. Nie, S.L. Zhao, Y.M. Li and W.T. Zhu for their assistance with EPMA and FESEM.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, J., Lu, G., Shi, X. et al. Improving Tribological Performance of Inconel 625 by Combining Groove-Textured Surfaces with Sn-Ag-Cu Solid Lubricant. J. of Materi Eng and Perform 30, 154–164 (2021). https://doi.org/10.1007/s11665-020-05363-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05363-y