Abstract

In this work, a systematic research is carried out to investigate the sintering kinetics of NiFe2O4 ceramic obtained by slip casting and pressureless sintering. The sintering shrinkage behaviors showed the linear shrinkage and linear shrinkage rate of the green body in the axial and radial directions, both increased with increasing sintering temperature, though the maximum linear shrinkage rate in the radial direction was acquired at a lower temperature (1280.7°C) than that in the axial direction (1305.4°C) for a denser compact. The temperature related to the maximum densification rate was about 1316.5°C while the relative density was around 72%. The characteristic sintering kinetics window exhibited that the sintering process could be typically divided into three stages. The sintering activation energy of the initial stage was 268.34 kJ mol−1, and the initial stage of the sintering process was controlled by both grain boundary diffusion and volume diffusion mechanisms. The grain growth kinetic analysis illustrated the grain growth exponent (n) reduced from 2.959 to 2.169 when the sintering temperature increased from 1300 to 1375°C, while the activation energy for grain growth decreased with both the increasing of sintering temperature and the shortening of holding time. It implied that the atomic diffusion process controlled the grain growth. In addition, it was observed that increases in the bending strength and elastic modulus reached its maximum value of 70.36 ± 1.03 MPa and 3.44 ± 0.53 GPa, respectively, mainly associated with the relatively dense microstructure.

Similar content being viewed by others

References

B. Wang, J.J. Du, Y.H. Liu, and G.C. Yao, Effect of TiO2 Doping on the Sintering Process, Mechanical and Magnetic Properties of NiFe2O4 Ferrite Ceramics, Int. J. Appl. Ceram. Technol., 2015, 12(3), p 658–664

K.E. Sickafus, J.M. Wills, and N.W. Grimes, Structure of Spinel, J. Am. Ceram. Soc., 1999, 82(12), p 3279–3292

A.T. Nelson, J.T. White, D.A. Andersson, J.A. Aguiar, K.J. McClellan, D.D. Byler, M.P. Short, and C.R. Stanek, Thermal Expansion, Heat Capacity, and Thermal Conductivity of Nickel Ferrite (NiFe2O4), J. Am. Ceram. Soc., 2014, 97(5), p 1559–1565

S. Briceño, W. Brämer-Escamilla, P. Silva, J. García, H. Del Castillo, M. Villarroel, J.P. Rodriguez, M.A. Ramos, R. Morales, and Y. Diaz, NiFe2O4/Activated Carbon Nanocomposite as Magnetic Material from Petcoke, J. Magn. Magn. Mater., 2014, 360, p 67–72

V. Manikandan, J.C. Denardin, S. Vigniselvan, and R.S. Mane, Structural, Dielectric and Enhanced Soft Magnetic Properties of Lithium (Li) Substituted Nickel Ferrite (NiFe2O4) Nanoparticles, J. Magn. Magn. Mater., 2018, 465, p 634–639

K. Kombaiah, J.J. Vijaya, L.J. Kennedy, and K. Kaviyarasu, Catalytic Studies of NiFe2O4 Nanoparticles Prepared by Conventional and Microwave Combustion Method, Mater. Chem. Phys., 2019, 221, p 11–28

Y. Tang, C.H. Yang, Y.W. Yang, X.T. Yin, W.X. Que, and J.F. Zhu, Three Dimensional Hierarchical Network Structure of S-NiFe2O4 Modified Few-Layer Titanium Carbides (MXene) Flakes on Nickel Foam as a High Efficient Electrocatalyst for Oxygen Evolution, Electrochim. Acta, 2019, 296, p 762–770

S.F. Zhang, W.H. Jiang, Y.W. Li, X.L. Yang, P. Sun, F.M. Liu, X. Yan, Y. Gao, X.S. Liang, J. Ma, and G.Y. Lu, Highly-Sensitivity Acetone Sensors based on Spinel-Type Oxide (NiFe2O4) through Optimization of Porous Structure, Sens. Actuators B, 2019, 291, p 266–274

X.F. Wang, K.M. Sun, S.J. Li, X.Z. Song, L. Cheng, and W. Ma, Porous Javelin-Like NiFe2O4 Nanorods as n-Propanol Sensor with Ultrahigh-Performance, ChemistrySelect, 2018, 3(45), p 12871–12877

D. Mandal, A. Gorai, and K. Mandal, Electromagnetic Wave Ttrapping in NiFe2O4 Nano-Hollow Spheres: An Efficient Microwave Absorber, J. Magn. Magn. Mater., 2019, 485, p 43–48

X.C. Gao, J.Q. Bi, W.L. Wang, H.Z. Liu, Y.F. Chen, X.X. Hao, X.N. Sun, and R. Liu, Morphology-Controllable Synthesis of NiFe2O4 Growing on Graphene Nanosheets as Advanced Electrode Material for High Performance Supercapacitors, J. Alloys Compd., 2020, 826, p 154088 (1–10)

S.B. Bandgar, M.M. Vadiyar, Y.C. Ling, J.Y. Chang, S.H. Han, A.V. Ghule, and S.S. Kolekar, Metal Precursor Dependent Synthesis of NiFe2O4 Thin Films for High Performance Flexible Symmetric Supercapacitor, ACS Appl. Energy Mater., 2018, 1(2), p 638–648

J.J. Du, Y.H. Liu, G.C. Yao, Z.S. Hua, X.L. Long, and B. Wang, Microstructure, Mechanical Properties, and Pyroconductivity of NiFe2O4 Composite Reinforced with ZrO2 Fibers, J. Mater. Eng. Perform., 2013, 22(6), p 1776–1782

P. Zarrabian, M. Kalantar, and S.S. Ghasemi, Fabrication and Characterization of Nickel Ferrite Based Inert Anodes for Aluminum Electrolysis, J. Mater. Eng. Perform., 2014, 23(5), p 1656–1664

D.W. Ni, K.B. Andersen, and V. Esposito, Sintering and Grain Growth Kinetics in La0.85Sr0.15MnO3-Ce0.9Gd0.1O1.95 (LSM-CGO) Porous Composite, J. Eur. Ceram. Soc., 2014, 34(15), p 3769–3778

H.D. Wu, W. Liu, L.F. Lin, Y.H. Li, Z. Tian, G.L. Nie, D. An, H.Z. Li, C.Y. Wang, Z.P. Xie, and S.H. Wu, Sintering Kinetics Involving Densification and Grain Growth of 3D printed Ce–ZrO2/Al2O3, Mater. Chem. Phys., 2020, 239, p 122069 (1–6)

A. Talimian and D. Galusek, Aqueous Slip Casting of Translucent Magnesium Aluminate Spinel: Effects of Dispersant Concentration and Solid Loading, Ceram. Int., 2019, 45(8), p 10646–10653

Y.H. Sun, W.H. Xiong, C.H. Li, and L. Yuan, Effect of Dispersant Concentration on Preparation of an Ultrahigh Density ZnO-Al2O3 Target by Slip Casting, J. Am. Ceram. Soc., 2009, 92(9), p 2168–2171

K. Moritz, N. Gerlach, J. Hubálková, and C.G. Aneziris, Pressure Slip Ccasting of Coarse-Grained Alumina-Carbon Materials, Int. J. Appl. Ceram. Technol., 2019, 16(1), p 14–22

Y. Liu, Y.C. Shu, X.Y. Zeng, B.S. Sun, P. Liang, Y. Zhang, C. Qiu, J.H. Yi, and J.L. He, Study on the Sintering Behavior and Characterization of the IGZO Ceramics by Slip Casting, Int. J. Appl. Ceram. Technol., 2019, 16(2), p 585–594

X.N. Sun, H.K. Wu, G.Z. Zhu, Y.C. Shan, J.J. Xu, J.T. Li, and E.A. Olevsky, Direct Coarse Powder Aqueous Slip Casting and Pressureless Sintering of Highly Transparent AlON Ceramics, Ceram. Int., 2020, 46(4), p 4850–4856

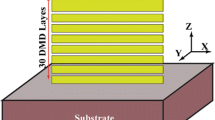

Z.G. Zhang, J.R. Xu, Z.K. Cao, and G.C. Yao, Fabrication of High-Density NiFe2O4 Ceramics by Slip Casting and Pressureless Sintering, Int. J. Appl. Ceram. Technol., 2020, 17(4), p 1811–1821

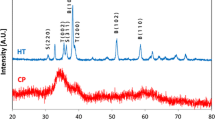

Z.G. Zhang, G.C. Yao, X. Zhang, J.F. Ma, and H. Lin, Synthesis and Characterization of Nickel Ferrite Nanoparticles via Planetary Ball Milling Assisted Solid-State Reaction, Ceram. Int., 2015, 41(3 Part B), p 4523–4530

S. Mitra, A.R. Kulkarni, and O. Prakash, Densification Behavior and Two Stage Master Sintering Curve in Lithium Sodium Niobate Ceramics, Ceram. Int., 2013, 39(S1), p S65–S68

W. Liu, Z.P. Xie, and L. Cheng, Sintering Kinetics Window: An Approach to the Densification Process during the Preparation of Transparent Alumina, Adv. Appl. Ceram., 2015, 114(1), p 33–38

D. An, W. Liu, Z.P. Xie, H.Z. Li, X.D. Luo, H.D. Wu, M.P. Huang, J.W. Liang, Z. Tian, and R.X. He, A Strategy for Defects Healing in 3D Printed Ceramic Compact via Cold Isostatic Pressing: Sintering Kinetic Window and Microstructure Evolution, J. Am. Ceram. Soc., 2018, 102(5), p 2263–2271

M. Lakusta, I. Danilenko, G. Volkova, L. Loladze, V. Burkhovetskiy, O. Doroshkevich, I. Brykhanova, I. Popova, and T. Konstantinova, Sintering Kinetics of ZrO2 Nanopowders Modified by Group IV Elements, Int. J. Appl. Ceram. Technol., 2019, 16(4), p 1481–1492

M.J. Bannister, Shape Sensitivity of Initial Sintering Equations, J. Am. Ceram. Soc., 1968, 51(10), p 548–553

J.R. Keski and I.B. Cutler, Initial Sintering of MnXO-Al2O3, J. Am. Ceram. Soc., 1968, 51(8), p 440–444

J.L. Woolfrey and M.J. Bannister, Nonisothermal Techniques for Studying Initial-Stage Sintering, J. Am. Ceram. Soc., 1972, 55(8), p 390–394

Z.G. Zhang, X.T. Lu, and J.L. Liu, NiFe2O4 Ceramic U-shaped Sleeve Prepared by Slip Casting and Pressureless Sintering, J. Inorg. Mater., 2020, 35(6), p 661–668

T. Senda and R.C. Bradt, Grain Growth in Sintered ZnO and ZnO-Bi2O3 Ceramics, J. Am. Ceram. Soc., 1990, 73(1), p 106–114

W.Y. Du, Y.L. Ai, W.H. Chen, W. He, J.J. Zhang, Y.Q. Fan, and Y.X. Gong, Grain Growth Kinetics and Growth Mechanism of Columnar Al2O3 Crystals in xNb2O5-7.5La2O3-Al2O3 Ceramic Composites, Ceram. Int., 2019, 45(6), p 6788–6794

M. Vaidya, A. Anupam, J.V. Bharadwaj, C. Srivastava, and B.S. Murty, Grain Growth Kinetics in CoCrFeNi and CoCrFeMnNi High Entropy A Processed by Spark Plasma Sintering, J Alloys Compd., 2019, 791, p 1114–1121

S.J. Guo, Powder Sintering Theory, Metallurgical Industry Press, Beijing, 1998

B. Wang, J.J. Du, Z. Fang, and P. Hu, Effect of TiO2 Addition on Grain Growth, Anodic Bubble Evolution and Anodic Overvoltage of NiFe2O4-Based Composite Inert Anodes, J. Mater. Eng. Perform., 2017, 26(11), p 5610–5619

Y. Liu, Y.L. Ai, W. He, W.H. Chen, and J.J. Zhang, Grain Growth Kinetics in Microwave Sintered Graphene Platelets Reinforced ZrO2/Al2O3 Composites, Ceram. Int., 2018, 44(14), p 16421–16427

D.C. Jia and G.M. Song, Properties of Inorganic Nonmetallic Materials, Science Press, Beijing, 2008

Acknowledgments

Financial supports from the Fundamental Research Funds for the Central Universities (No. N182504015), Liaoning Revitalization Talents Program (No. XLYC1902097) and Program Liaoning Innovation Talents in University (No. LR2018011), were gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Z., Cao, Z., Zu, G. et al. Pressureless Sintering Kinetics of NiFe2O4 Ceramic Fabricated by Slip Casting. J. of Materi Eng and Perform 29, 7899–7907 (2020). https://doi.org/10.1007/s11665-020-05313-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05313-8