Abstract

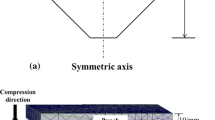

The dynamic recrystallization (DRX) behavior of INCONEL 690 (IN690) alloy was studied using electron backscatter diffraction (EBSD) and transmission electron microscopy. Isothermal compression tests were performed on a Gleeble-3500 simulator under temperatures 950-1100 °C, strain rates 0.01-1 s−1, and the maximum true strain 0.8. An Avrami-type model was developed to investigate the DRX behavior of IN690; it was found to be extremely sensitive to the processing parameters of temperature, strain rate, and true strain. As temperature increased and strain rate decreased, the activation energy increased, thus accelerating movement of dislocation and migration of grain boundaries, causing DRX behavior acceleration. The DRX behavior is accompanied by dislocation rearrangement and annihilation. The DRX mechanism of IN690 is dominated by discontinuous dynamic recrystallization (DDRX) and supplemented by continuous dynamic recrystallization (CDRX). A key characteristic of DDRX is grain-boundary bulges, while CDRX features progressive sub-grain rotation, leading to migration of low-angle grain boundaries to high-angle grain boundaries. A series of constitutive models were embedded into finite-element method software to study the DRX behavior of IN690. The results show that the microstructure evolution regularity obtained by the simulation method is consistent with the experimental values, which provides a basis for computer simulations of the hot machining process.

Similar content being viewed by others

References

J. Kai, G. Yu, C. Tsai, M. Liu, and S. Yao, The Effects of Heat Treatment on the Chromium Depletion, Precipitate Evolution, and Corrosion Resistance of INCONEL Alloy 690, Metall. Trans. A, 1989, 20(10), p 2057–2067

H. Jiang, L. Yang, J. Dong, M. Zhang, and Z. Yao, The Recrystallization Model and Microstructure Prediction of Alloy 690 During Hot Deformation, Mater. Des., 2016, 104, p 162–173

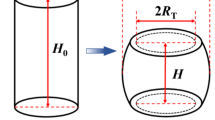

J. Wang and S.-C. Zhai, Dynamic Recrystallization Kinetics of 690 Alloy During Hot Compression of Double-cone Samples, J. Mater. Eng. Perform., 2017, 26(3), p 1433–1443

B. Wang, S.-H. Zhang, M. Cheng, and H.-W. Song, Dynamic Recrystallization Mechanism of Inconel 690 Superalloy During Hot Deformation at High Strain Rate, J. Mater. Eng. Perform., 2013, 22(8), p 2382–2388

G.-z. Quan, R.-j. Shi, Z. Jiang, L. Qiao, W. Xiong, and H.-m. Qiu, Modeling of Dynamic Recrystallization Volume Fraction Evolution for AlCu4SiMg Alloy and Its Application in FEM, Trans. Nonferrous Met. Soc. China, 2019, 29(6), p 1138–1151

M.-S. Chen, Z.-H. Zou, Y. Lin, H.-B. Li, and W.-Q. Yuan, Effects of Annealing Parameters on Microstructural Evolution of a Typical Nickel-Based Superalloy During Annealing Treatment, Mater. Charact., 2018, 141, p 212–222

M.-S. Chen, W.-Q. Yuan, H.-B. Li, and Z.-H. Zou, New Insights on the Relationship Between Flow Stress Softening and Dynamic Recrystallization Behavior of Magnesium Alloy AZ31B, Mater. Charact., 2019, 147, p 173–183

C. Bennett, A Comparison of Material Models for the Numerical Simulation of Spike-Forging of a CrMoV Alloy Steel, Comput. Mater. Sci., 2013, 70, p 114–122

X. Yang, A. He, C. Wu, S. Li, H. Zhang, and X. Wang, Study of Static Recrystallization Behavior of a Nitrogen-Alloyed Ultralow Carbon Austenitic Stainless Steel by Experiment and Simulation, J. Mater. Eng. Perform., 2015, 24(11), p 4346–4357

J. Favre, D. Fabrègue, K. Yamanaka, and A. Chiba, Modeling Dynamic Recrystallization of L-605 Cobalt Superalloy, Mater. Sci. Eng., A, 2016, 653, p 84–92

D. Jia, W. Sun, D. Xu, and F. Liu, Dynamic Recrystallization Behavior of GH4169G Alloy During Hot Compressive Deformation, J. Mater. Sci. Technol., 2019, 35(9), p 1851–1859

Y. Lin, M.-S. Chen, and J. Zhong, Effects of Deformation Temperatures on Stress/Strain Distribution and Microstructural Evolution of Deformed 42CrMo Steel, Mater. Des., 2009, 30(3), p 908–913

G. Ebrahimi, A. Momeni, H. Ezatpour, M. Jahazi, and P. Bocher, Dynamic Recrystallization in Monel400 Ni-Cu Alloy: Mechanism and Role of Twinning, Mater. Sci. Eng., A;, 2019, 744, p 376–385

S. Mitsche, P. Pölt, and C. Sommitsch, Recrystallization Behaviour of the Nickel‐Based Alloy 80 A During Hot Forming, J. Microsc., 2007, 227(3), p 267–274

Z. Wan, Y. Sun, L. Hu, and H. Yu, Dynamic Softening Behavior and Microstructural Characterization of TiAl-Based Alloy During Hot Deformation, Mater. Charact., 2017, 130, p 25–32

S. Wang, M. Zhang, H. Wu, and B. Yang, Study on the Dynamic Recrystallization Model and Mechanism of Nuclear Grade 316LN Austenitic Stainless Steel, Mater. Charact., 2016, 118, p 92–101

Y. Ning, T. Wang, M. Fu, M. Li, L. Wang, and C. Zhao, Competition between Work-Hardening Effect and Dynamic-Softening Behavior for Processing As-cast GH4720Li Superalloys with Original Dendrite Microstructure During Moderate-Speed Hot Compression, Mater. Sci. Eng., A, 2015, 642, p 187–193

F. Zhang, J.L. Sun, J. Shen, X.D. Yan, and J. Chen, Flow Behavior and Processing Maps of 2099 Alloy, Mater. Sci. Eng., A;, 2014, 613, p 141–147

W. Roberts and B. Ahlblom, A Nucleation Criterion for Dynamic Recrystallization During Hot Working, Acta Metall., 1978, 26(5), p 801–813

H. Zhang, K. Zhang, S. Jiang, H. Zhou, C. Zhao, and X. Yang, Dynamic Recrystallization Behavior of a γ′-Hardened Nickel-Based Superalloy During Hot Deformation, J. Alloys Compd., 2015, 623, p 374–385

T. Sakai, Dynamic Recrystallization Microstructures Under Hot Working Conditions, J. Mater. Process. Technol., 1995, 53(1–2), p 349–361

F. Qin, H. Zhu, Z. Wang, X. Zhao, W. He, and H. Chen, Dislocation and Twinning Mechanisms for Dynamic Recrystallization of As-cast Mn18Cr18N Steel, Mater. Sci. Eng., A, 2017, 684, p 634–644

Y. Lin, X.-Y. Wu, X.-M. Chen, J. Chen, D.-X. Wen, J.-L. Zhang, and L.-T. Li, EBSD Study of a Hot Deformed Nickel-Based Superalloy, J. Alloys Compd., 2015, 640, p 101–113

Z. Bi, M. Zhang, J. Dong, K. Luo, and J. Wang, A New Prediction Model of Steady State Stress Based on the Influence of the Chemical Composition for Nickel-base Superalloys, Mater. Sci. Eng., A, 2010, 527(16-17), p 4373–4382

E. Poliak and J. Jonas, A One-parameter Approach to Determining the Critical Conditions for the Initiation of Dynamic Recrystallization, Acta Mater., 1996, 44(1), p 127–136

K. Wang, M. Fu, S. Lu, and X. Li, Study of the Dynamic Recrystallization of Ti–6.5 Al–3.5 Mo–1.5 Zr–0.3 Si Alloy in β-Forging Process Via Finite Element Method Modeling and Microstructure Characterization, Mater. Des., 2011, 32(3), p 1283–1291

M.-S. Chen, Y. Lin, and X.-S. Ma, The Kinetics of Dynamic Recrystallization of 42CrMo Steel, Mater. Sci. Eng., A, 2012, 556, p 260–266

J. Wang, J. Dong, M. Zhang, and X. Xie, Hot Working Characteristics of Nickel-Base Superalloy 740H During Compression, Mater. Sci. Eng., A, 2013, 566, p 61–70

S. Mandal, A. Bhaduri, and V.S. Sarma, Role of Twinning on Dynamic Recrystallization and Microstructure During Moderate to High Strain Rate Hot Deformation of a Ti-Modified Austenitic Stainless Steel, Metall. Mater. Trans. A, 2012, 43(6), p 2056–2068

P. Haijian, L. Defu, G. Shengli, G. Qingmiao, H. Jie, W. Zhigang, Hot Deformation Behavior of GH690 Alloy, Chin. J. Rare Met., 2011, 3, p 356–361

J. Wang, H. Xiao, H. Xie, X. Xu, and Y. Gao, Study on Hot Deformation Behavior of Carbon Structural Steel with Flow Stress, Mater. Sci. Eng., A, 2012, 539, p 294–300

Y. Xu, L. Hu, and Y. Sun, Deformation Behaviour and Dynamic Recrystallization of AZ61 Magnesium Alloy, J. Alloys Compd., 2013, 580, p 262–269

X. Li, L. Duan, J. Li, X. Wu, Experimental Study and Numerical Simulation of Dynamic Recrystallization Behavior of a Micro-Alloyed Plastic Mold Steel. Mater. Des. (1980–2015), 2015, 66, p 309-320

S.H. Zahiri, C.H. Davies, and P.D. Hodgson, A Mechanical Approach to Quantify Dynamic Recrystallization in Polycrystalline Metals, Scr. Mater., 2005, 52(4), p 299–304

Z. Wan, Y. Sun, L. Hu, and H. Yu, Experimental Study and Numerical Simulation of Dynamic Recrystallization Behavior of TiAl-Based Alloy, Mater. Des., 2017, 122, p 11–20

G. Kugler and R. Turk, Modeling the Dynamic Recrystallization Under Multi-stage Hot Deformation, Acta Mater., 2004, 52(15), p 4659–4668

M. Zouari, N. Bozzolo, and R.E. Loge, Mean Field Modelling of Dynamic and Post-dynamic Recrystallization During Hot Deformation of Inconel 718 in the Absence of δ Phase Particles, Mater. Sci. Eng., A, 2016, 655, p 408–424

H. Mirzadeh, J. Cabrera, A. Najafizadeh, and P. Calvillo, EBSD Study of a Hot Deformed Austenitic Stainless Steel, Mater. Sci. Eng., A, 2012, 538, p 236–245

A. Rollett, F. Humphreys, G. Rohrer, and M. Hatherly, Recrystallization and Related Annealing Phenomena, Elsevier, 2004, 2, p 121–167

D.-F. Li, D.-Z. Zhang, S.-d. Liu, Z.-j. Shan, X.-m. Zhang, W. Qin, and S.-Q. Han, Dynamic Recrystallization Behavior of 7085 Aluminum Alloy During Hot Deformation, Trans. Nonferrous Met. Soc. China, 2016, 26(6), p 1491–1497

C. Zhang, C. Wang, R. Guo, G. Zhao, L. Chen, W. Sun, and X. Wang, Investigation of Dynamic Recrystallization and Modeling of Microstructure Evolution of an Al-Mg-Si Aluminum Alloy During High-temperature Deformation, J. Alloys Compd, 2019, 773, p 59–70

W. Chen, B. Hu, C. Jia, C. Zheng, and D. Li, Continuous Dynamic Recrystallization During the Transient Deformation in a Ni-30% Fe Austenitic Model Alloy, Mater. Sci. Eng., A, 2019, 751, p 10–14

L. Li, J. Luo, J. Yan, and M. Li, Dynamic Globularization and Restoration Mechanism of Ti–5Al–2Sn–2Zr–4Mo–4Cr Alloy During Isothermal Compression, J. Alloys Compd., 2015, 622, p 174–183

D. Ponge and G. Gottstein, Necklace Formation During Dynamic Recrystallization: Mechanisms and Impact on Flow Behavior, Acta Mater., 1998, 46(1), p 69–80

S. Mandal, A. Bhaduri, and V.S. Sarma, A Study on Microstructural Evolution and Dynamic Recrystallization During Isothermal Deformation of a Ti-modified Austenitic Stainless Steel, Metall. Mater. Trans. A, 2011, 42(4), p 1062–1072

D. Li, Q. Guo, S. Guo, H. Peng, and Z. Wu, The Microstructure Evolution and Nucleation Mechanisms of Dynamic Recrystallization in Hot-deformed Inconel 625 Superalloy, Mater. Des., 2011, 32(2), p 696–705

H. Kou, Y. Chen, B. Tang, Y. Cui, F. Sun, J. Li, and X. Xue, An Experimental Study on the Mechanism of Texture Evolution During Hot-Rolling Process in a β Titanium Alloy, J. Alloys Compd., 2014, 603, p 23–27

Acknowledgments

The authors are grateful to financial support from the Jiangsu Province Key Laboratory of High-end Structural Materials (hsm1808).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, D.S., Shang, X.Y., Wang, W. et al. Dynamic Recrystallization Modeling and Mechanisms in Inconel 690 Alloy during Hot Compressive Deformation. J. of Materi Eng and Perform 29, 7188–7197 (2020). https://doi.org/10.1007/s11665-020-05213-x

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05213-x