Abstract

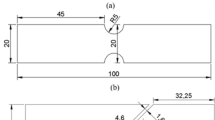

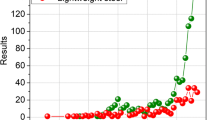

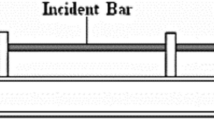

High-strength steel is an effective choice to satisfy the demands of advanced manufacturing engineering and construction engineering. The complex and severe working environments for high-strength steel require the designer to take the dynamic mechanical properties into consideration. Thus, the main subjects of this paper are the dynamic strain–stress relationship and the strain rate-strengthening effect of S890 high-strength steel. Experimental studies with a wide range of strain rates were conducted using a dynamic tensile testing system (for intermediate strain rate) and a Split Hopkinson Pressure Bar testing system (for high strain rate). The strain rate effect of S890 steel was quantitatively investigated. The global dynamic increase factor (DIFavg) values were tested to be 1.132 at a strain rate of 200 s−1 and 1.214 at 5292.8 s−1, which indicates that S890 high-strength steel was less sensitive to strain rates than mild steel and other structural steels with lower strength. Based on the Johnson–Cook (J–C) model and the Cowper–Symonds (C–S) model, strain rate models for the S890 steel are presented for describing the dynamic stress–strain relationship. The C–S model has better accuracy owing to the nonlinear characteristic of the DIFavg of S890 steel.

Similar content being viewed by others

References

EN 10025-6:2019, Hot Rolled Products of Structural Steels, Part 6: Technical Delivery Conditions for Flat Products of High Yield Strength Structural Steels in the Quenched and Tempered Condition, European-Committee for Standardization, Brussels (2019)

N. Enzinger, H. Cerjak, E. Roos, and U. Eisele, Fracture Mechanical Investigation of Steel Grade S890 Used in Cleuson–Dixence Hydropower Plant Shaft, Sci. Technol. Weld. Join., 2006, 11(4), p 422–428

A. Akyel, M.H. Kolstein, and F.S.K. Bijlaard, Fatigue Strength of Repaired Cracks in Base Material of High Strength Steels, J. Constr. Steel Res., 2017, 139, p 374–384

A. Akyel, M.H. Kolstein, and F.S.K. Bijlaard, Fatigue Strength of Repaired Welded Connections Made of Very High Strength Steels, Eng. Struct., 2018, 161, p 28–40

D. Yang, X. Wang, Z. Liu, and Y. Sun, Study on SH-CCT Diagram and Weldability of S890 Steel, Adv. Mater. Res., 2012, 415-417, p 865–868

D. Yang and Y. Sun, Thermal Simulation Study of 900 MPa Grade High-Strength Low Alloy Steel in Welding Procedures, J. Comput. Theor. Nanosci., 2012, 9, p 1222–1225

L. Huang, G. Li, X. Wang, C. Zhang, L. Choe, and M. Engelhardt, High Temperature Mechanical Properties of High Strength Structural Steels Q550, Q690 and Q890, Fire Technol., 2018, 54(6), p 1609–1628

H. Zhao, A Constitutive Model for Metals Over a Large Range of Strain Rates Identification for Mild-Steel and Aluminium Sheets, Mater. Sci. Eng., A, 1997, 230, p 95–99

N.K. Singh, E. Cadoni, M.K. Singha, and N.K. Gupta, Dynamic Tensile and Compressive Behaviors of Mild Steel at Wide Range of Strain Rates, J. Eng. Mech., 2013, 139(9), p 1197–1206

N. Jones, Structural Impact, 2nd ed., Cambridge University Press, Cambridge, 2012

W. Yu, J. Zhao, and J. Shi, Dynamic Mechanical Behaviour of Q345 Steel at Elevated Temperatures: Experimental Study, Mater. High Temp., 2010, 27(3), p 285–293

D. Forni, B. Chiaia, and E. Cadoni, Strain Rate Behavior in Tension of S355 Steel: Base for Progressive Collapse Analysis, Eng. Struct., 2016, 119, p 164–173

J. Chen, W. Shu, and J. Li, Constitutive Model of Q345 Steel at Different Intermediate Strain Rates, Int. J. Steel Struct., 2017, 17(1), p 127–137

J. Chen, J. Li, and Z. Li, Experiment Research on Rate-Dependent Constitutive Model of Q420 Steel, Constr. Build. Mater., 2017, 153, p 816–823

H. Yang, X. Yang, A.H. Varma, and Y. Zhu, Strain-Rate Effect and Constitutive Models for Q550 High-Strength Structural Steel, J. Mater. Eng. Perform., 2019, 28, p 6626–6637

X. Yang, H. Yang, and S. Zhang, Rate-Dependent Constitutive Models of S690 High-Strength Structural Steel, Constr. Build. Mater., 2019, 198, p 597–607

X. Yang, H. Yang, Z. Lai, and S. Zhang, Dynamic Tensile Behavior of S690 High-Strength Structural Steel at Intermediate Strain Rates, J. Constr. Steel Res., 2020, 168, p 105961

A.A. Alabi, P.L. Moore, L.C. Wrobel, J.C. Campbell, and W. He, Tensile Behavior of S690QL and S960QL under High Strain Rate, J. Constr. Steel Res., 2018, 150, p 570–580

E. Cadoni and D. Forni, Mechanical Behaviour of a Very-High Strength Steel (S960QL) under Extreme Conditions of High Strain Rates and Elevated Temperatures, Fire Saf. J., 2019, 109, p 102869

I. Rohr, H. Nahme, and K. Thoma, Material Characterization and Constitutive Modelling of Ductile High Strength Steel for a Wide Range of Strain Rates, Int. J. Impact Eng, 2005, 31, p 401–433

ISO 6892-1:2016, Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature, The International Organization for Standardization, 2016

ISO 26203-2:2011, Metallic Materials—Tensile Testing at High Strain Rates—Part 2: Servo-hydraulic and Other Test Systems. The International Organization for Standardization (2011)

Y. Zhang, J.A. Sharon, G.L. Hu, K.T. Ramesh, and K.J. Hemker, Stress-Driven Grain Growth in Ultrafine Grained Mg Thin Film, Scr. Mater., 2013, 68, p 424–427

G. Subhash, R.J. Dowding, and L.J. Kecskes, Characterization of Uniaxial Compressive Response of Bulk Amorphous Zr-Ti-Cu-Ni-Be Alloy, Mater. Sci. Eng., A, 2002, 334, p 33–40

Z. Wang and P. Li, Dynamic Failure and Fracture Mechanism in Alumina Ceramics: Experimental Observations and Finite Element Modeling, Ceram. Int., 2015, 41, p 12763–12772

S. Sarva and S. Nemat-Nasser, Dynamic Compressive Strength of Silicon Carbide under Uniaxial Compression, Mater. Sci. Eng., A, 2001, 317, p 140–144

G.R. Johnson and W.H. Cook, A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates and High Temperatures. in Proceedings of the 7th International Symposium on Ballistics, Den Haag, The Netherlands (1983)

G.R. Cowper and P.S. Symonds, Strain-Hardening and Strain-Rate Effects in the Impact Loading of Cantilever Beams. Brown University Research Report, Division of Applied Mathematics (1957)

Acknowledgments

The research in this paper was sponsored by the National Natural Science Foundation of China (Grant No. 51678194).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, Y., Yang, H. & Zhang, S. Dynamic Mechanical Behavior and Constitutive Models of S890 High-Strength Steel at Intermediate and High Strain Rates. J. of Materi Eng and Perform 29, 6727–6739 (2020). https://doi.org/10.1007/s11665-020-05150-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-05150-9