Abstract

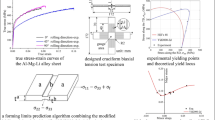

This paper studies the anisotropy behavior and forming limit of 5182-H111 aluminum alloy by experiments and theoretical analysis. The uniaxial tension tests for three different sheet directions were conducted to investigate the anisotropic properties of Al5182-H111 sheet. Moreover, the Nakajima tests for both rolling and transverse directions were performed to get the forming limit data. The experimental results show that the forming limit curves (FLCs) for rolling direction are much lower than that for transverse direction. In order to further investigate the influence of anisotropic properties on FLCs, the theoretical prediction of FLC was accomplished based on three different hardening laws. The results show that the theoretical FLC with Ghosh hardening law has much better agreement with experimental data. Furthermore, a new FLC was proposed by extending the forming limit from the strain state of uniaxial tension at transverse direction to the strain state of uniaxial tension at rolling direction. The adaptability of new FLC was verified in the Drawing test and Erichsen cupping test.

Similar content being viewed by others

References

J. Hirsch, Recent Development in Aluminium for Automotive Applications, Trans. Nonferrous Met. Soc. China, 2014, 24(7), p 1995–2002

T.B. Stoughton and X. Zhu, Review of Theoretical Models of the Strain-Based FLD and Their Relevance to the Stress-Based FLD, Int. J. Plast, 2004, 20(8), p 1463–1486

M. Darrieulat and F. Montheillet, Extension of the Hill (1948) yield criterion to the case of prismatic monoclinic symmetry, Int. J. Mech. Sci., 1996, 38(12), p 1273–1284

G. Sainath, B.K. Choudhary, J. Christopher, E. Isaac Samuel, and M.D. Mathew, Applicability of Voce Equation for Tensile Flow and Work Hardening Behaviour of P92 Ferritic Steel, Int. J. Press. Vessels Pip., 2015, 132–133, p 1–9

J.E. Hockett and O.D. Sherby, Large Strain Deformation of Polycrystalline Metals at Low Homologous Temperatures, J. Mech. Phys. Solids, 1975, 23(2), p 87–98

I.Y. Straume and V.I. Prosvirin, Investigation of the Wedge Pressure (Ludwik) Method of Testing Certain Plastics, Polym. Mech., 1971, 7(2), p 330–332

H.W. Swift, Plastic Instability Under Plane Stress, J. Mech. Phys. Solids, 1952, 1(1), p 1–18

A.K. Ghosh, The Influence of Strain Hardening and Strain-Rate Sensitivity on Sheet Metal Forming, J. Eng. Mater. Technol., 1977, 99(3), p 264

F. Djavanroodi, M. Ebrahimi, and M. Janbakhsh, A Study on the Stretching Potential, Anisotropy Behavior and Mechanical Properties of AA7075 and Ti-6Al-4 V Alloys Using Forming Limit Diagram: An Experimental, Numerical and Theoretical Approaches, Results Phys., 2019, 14, p 102496

J. He, Y. Li, B. Gu, and S. Li, Effects of Reverse Loading on Forming Limit Predictions with Distortional Anisotropic Hardening Under Associated and Non-associated Flow Rules, Int. J. Mech. Sci., 2019, 156, p 446–461

J. He, D. Zeng, X. Zhu, Z. Cedric Xia, and S. Li, Effect of Nonlinear Strain Paths on Forming Limits Under Isotropic and Anisotropic Hardening, Int. J. Solids Struct., 2014, 51(2), p 402–415

R. Schneider, R.J. Grant, N. Sotirov, G. Falkinger, F. Grabner, C. Reichl, M. Scheerer, B. Heine, and Z. Zouaoui, Constitutive Flow Curve Approximation of Commercial Aluminium Alloys at Low Temperatures, Mater. Des., 2015, 88, p 659–666

Z. Marciniak and K. Kuczyński, Limit Strains in the Processes of Stretch-Forming Sheet Metal, Int. J. Mech. Sci., 1967, 9(9), p 609–620

P. Hora, L. Tong, and B. Berisha, Modified Maximum Force Criterion, a Model for the Theoretical Prediction of Forming Limit Curves, Int. J. Mater. Form., 2013, 6(2), p 267–279

Y. Wang, C. Zhang, Y. Yang, S. Fan, G. Wang, G. Zhao, and L. Chen, The Integration of Through-Thickness Normal Stress and Friction Stress in the M–K Model to Improve the Accuracy of Predicted FLCs, Int. J. Plast, 2019, 120, p 147–163

B.L. Ma, M. Wan, Z.Y. Cai, W.N. Yuan, C. Li, X.D. Wu, and W. Liu, Investigation on the Forming Limits of 5754-O Aluminum Alloy Sheet with the Numerical Marciniak–Kuczynski Approach, Int. J. Mech. Sci., 2018, 142–143, p 420–431

Q. Hu, X. Li, and J. Chen, New Robust Algorithms for Marciniak–Kuczynski Model to Calculate the Forming Limit Diagrams, Int. J. Mech. Sci., 2018, 148, p 293–306

J. Lian, F. Shen, X. Jia, D.-C. Ahn, D.-C. Chae, S. Münstermann, and W. Bleck, An Evolving Non-associated Hill48 Plasticity Model Accounting for Anisotropic Hardening and r-value Evolution and Its Application to Forming Limit Prediction, Int. J. Solids Struct., 2018, 151, p 20–44

Q.-T. Pham, B.-H. Lee, K.-C. Park, and Y.-S. Kim, Influence of the Post-necking Prediction of Hardening Law on the Theoretical Forming Limit Curve of Aluminium Sheets, Int. J. Mech. Sci., 2018, 140, p 521–536

K. Jawale, J.F. Duarte, A. Reis, and M.B. Silva, Characterizing Fracture Forming Limit and Shear Fracture Forming Limit for Sheet Metals, J. Mater. Process. Technol., 2018, 255, p 886–897

J.P. Magrinho, M.B. Silva, G. Centeno, F. Moedas, C. Vallellano, and P.A.F. Martins, On the Determination of Forming Limits in Thin-Walled Tubes, Int. J. Mech. Sci., 2019, 155, p 381–391

Q. Hu, X. Li, and J. Chen, Forming Limit Evaluation by Considering Through-Thickness Normal Stress: Theory and Modeling, Int. J. Mech. Sci., 2019, 155, p 187–196

B.L. Ma, M. Wan, H. Zhang, X.L. Gong, and X.D. Wu, Evaluation of the Forming Limit Curve of Medium Steel Plate Based on Non-constant Through-Thickness Normal Stress, J. Manuf. Process., 2018, 33, p 175–183

N. Park, H. Huh, S.J. Lim, Y. Lou, Y.S. Kang, and M.H. Seo, Fracture-Based Forming Limit Criteria for Anisotropic Materials in Sheet Metal Forming, Int. J. Plast, 2017, 96, p 1–35

S.B. Kim, H. Huh, H.H. Bok, and M.B. Moon, Forming Limit Diagram of Auto-Body Steel Sheets for High-Speed Sheet Metal Forming, J. Mater. Process. Technol., 2011, 211(5), p 851–862

S. Bruschi, T. Altan, D. Banabic, P.F. Bariani, A. Brosius, J. Cao, A. Ghiotti, M. Khraisheh, M. Merklein, and A.E. Tekkaya, Testing and Modelling of Material Behaviour and Formability in Sheet Metal Forming, CIRP Ann. Manuf. Technol., 2014, 63(2), p 727–749

J. Chen, P. Gong, and L. Yang, Forming Limit Evaluation for AA5182 Aluminum Alloy at Warm Temperatures Based on M–K Model, J. Mater. Eng. Perform., 2020, 29, p 1176–1184

M. Kawka and A. Makinouchi, Plastic Anisotropy in FEM Analysis Using Degenerated Solid Element, J. Mater. Process. Technol., 1996, 60(1), p 239–242

H. Kim, J.H. Sung, R. Sivakumar, and T. Altan, Evaluation of Stamping Lubricants Using the Deep Drawing Test, Int. J. Mach. Tool Manuf., 2007, 47(14), p 2120–2132

T. Sangkharat and S. Dechjarern, Using Image Processing on Erichsen Cup Test Machine to Calculate Anisotropic Property of Sheet Metal, Proc. Manuf., 2019, 29, p 390–397

S. Basak, S.K. Panda, and M.-G. Lee, Formability and Fracture in Deep Drawing Sheet Metals: Extended Studies for Pre-strained Anisotropic Thin Sheets, Int. J. Mech. Sci., 2020, 170, p 105346

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hou, Z., Liu, Z., Wan, M. et al. An Investigation on Anisotropy Behavior and Forming Limit of 5182-H111 Aluminum Alloy. J. of Materi Eng and Perform 29, 3745–3756 (2020). https://doi.org/10.1007/s11665-020-04879-7

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04879-7