Abstract

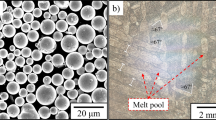

Low-cycle fatigue and creep-fatigue tests were conducted at 815 °C on laser-welded, selective laser melted (SLM) Inconel 625 test specimens. The results showed that the microstructure of the welding zone was mainly composed of columnar dendrites, which grew epitaxially from the weld line and exhibited better fatigue and durability resistance than the non-welded SLM alloy. The low-cycle fatigue life and creep-fatigue life decreased with increasing test stress. Both fatigue and creep-fatigue properties were better for laser-welded SLM Inconel 625 specimens than non-welded specimens. High-density intergranular cracks formed in the \(\gamma\) matrix at base material, which contained many intergranular precipitates. Precipitation of intermetallic \(\delta\), \(\gamma^{\prime\prime}\), and the intergranular carbides was responsible for the higher hardness of the fatigue and creep-fatigue specimens.

Similar content being viewed by others

References

C.A. Badrish, N. Kotkunde, G. Mahalle, S.K. Singh, and K. Mahesh, Analysis of Hot Anisotropic Tensile Flow Stress and Strain Hardening Behavior for Inconel 625 Alloy, J. Mater. Eng. Perform., 2019, 28(12), p 7537–7553

C.A. Badrish, N. Kotkunde, O. Salunke, and S. Kumar Singh, Study of Anisotropic Material Behavior for Inconel 625 Alloy at Elevated Temperatures, Mater. Today Proc., 2019, 18, p 2760–2766

V. Shankar, K.B.S. Rao, and S.L. Mannan, Microstructure and Mechanical Properties of Inconel 625 Superalloy, J. Nucl. Mater., 2001, 288(2), p 222–232

K. Inaekyan, A. Kreitcberg, S. Turenne, and V. Brailovski, Microstructure and Mechanical Properties of Laser Powder Bed-Fused IN625 Alloy, Mater. Sci. Eng. A, 2019, 768, p 138481

N.T. Aboulkhair, M. Simonelli, L. Parry, I. Ashcroft, C. Tuck, and R. Hague, 3D Printing of Aluminium Alloys: Additive Manufacturing of Aluminium Alloys Using Selective Laser Melting, Prog. Mater Sci., 2019, 106, p 100578

J. Zhang, B. Song, Q. Wei, D. Bourell, and Y. Shi, A Review of Selective Laser Melting of Aluminum Alloys: Processing, Microstructure, Property and Developing Trends, J. Mater. Sci. Technol., 2019, 35(2), p 270–284

L. Xi, S. Chen, M. Wei, J. Liang, C. Liu, and M. Wang, Microstructural Evolution and Properties of 24CrNiMoY Alloy Steel Fabricated by Selective Laser Melting, J. Mater. Eng. Perform., 2019, 28(9), p 5521–5532

G. Dursun, S. Ibekwe, G. Li, P. Mensah, G. Joshi, and D. Jerro, Influence of Laser Processing Parameters on the Surface Characteristics of 316L Stainless Steel Manufactured by Selective Laser Melting, Mater. Today: Proc. 2020 (in press) https://doi.org/10.1016/j.matpr.2019.12.061

H. Shipley, D. McDonnell, M. Culleton, R. Coull, R. Lupoi, G. O’Donnell, and D. Trimble, Optimisation of Process Parameters to Address Fundamental Challenges During Selective Laser Melting of Ti-6Al-4 V: A Review, Int. J. Mach. Tool. Manu., 2018, 128, p 1–20

L. Zhou, T. Yuan, J. Tang, J. He, and R. Li, Mechanical and Corrosion Behavior of Titanium Alloys Additively Manufactured by Selective Laser Melting—A Comparison Between Nearly β Titanium, α Titanium and α + β Titanium, Opt. Laser Technol., 2019, 119, p 105625

G.E. Bean, T.D. McLouth, D.B. Witkin, S.D. Sitzman, P.M. Adams, and R.J. Zaldivar, Build Orientation Effects on Texture and Mechanical Properties of Selective Laser Melting Inconel 718, J. Mater. Eng. Perform., 2019, 28(4), p 1942–1949

S. Periane, A. Duchosal, S. Vaudreuil, H. Chibane, A. Morandeau, J. Cormier, and R. Leroy, Machining Influence on the Fatigue Resistance of Inconel 718 Fabricated by Selective Laser Melting (SLM), Proc. Struct. Integr., 2019, 19, p 415–422

C. Pleass and S. Jothi, Influence of Powder Characteristics and Additive Manufacturing Process Parameters on the Microstructure and Mechanical Behaviour of Inconel 625 Fabricated by Selective Laser Melting, Addit. Manuf., 2018, 24, p 419–431

X. Hu, Z. Xue, G. Zhao, J. Yun, D. Shi, and X. Yang, Laser Welding of a Selective Laser Melted Ni-base Superalloy: Microstructure and High Temperature Mechanical Property, Mater. Sci. Eng., A, 2019, 745, p 335–345

S. Li, Q. Wei, Y. Shi, Z. Zhu, and D. Zhang, Microstructure Characteristics of Inconel 625 Superalloy Manufactured by Selective Laser Melting, J. Mater. Sci. Technol., 2015, 31(9), p 946–952

P. Wang, B. Zhang, C.C. Tan, S. Raghavan, Y.-F. Lim, C.-N. Sun, J. Wei, and D. Chi, Microstructural Characteristics and Mechanical Properties of Carbon Nanotube Reinforced Inconel 625 Parts Fabricated by Selective Laser Melting, Mater. Design., 2016, 112, p 290–299

L. Chao, R. White, X.Y. Fang, M. Weaver, and Y.B. Guo, Microstructure Evolution Characteristics of Inconel 625 Alloy from Selective Laser Melting to Heat Treatment, Mater. Sci. Eng., A, 2017, 705, p 20–31

J.P. Oliveira, T.G. Santos, and R.M. Miranda, Revisiting Fundamental Welding Concepts to Improve Additive Manufacturing: From Theory to Practice, Prog. Mater Sci., 2020, 107, p 100590

K.D. Ramkumar, S.G. Pattapu, S. Vangaveeti, K. Kothari, R. Sridhar, N. Arivazhagan, and P. Kuppan, Studies on Microstructure and Mechanical Properties of Keyhole Mode Nd:YAG Laser Welded Inconel 625 and Duplex Stainless Steel, SAF 2205, J. Mater. Res., 2015, 30, p 1–11

Y.S. Park, J.J. Choi, and D.H. Bae, Fracture Mechanical Assessment of the Corrosion Fatigue Characteristics at the Low Fatigue Limit of a Multi-pass Welded Ni-based Alloy 617, Procedia Mater. Sci., 2014, 3, p 1530–1535

K.G. Kumar, K.D. Ramkumar, and N. Arivazhagan, Characterization of Metallurgical and Mechanical Properties on the Multi-pass Welding of Inconel 625 and AISI, 316L, J. Mech. Sci. Technol., 2015, 29(3), p 1039–1047

C.A. Biffi, J. Fiocchi, and A. Tuissi, Laser Weldability of AlSi10Mg Alloy Produced by Selective Laser Melting: Microstructure and Mechanical Behavior, J. Mater. Eng. Perform., 2019, 28(11), p 6714–6719

F. Caiazzo, V. Alfieri, F. Cardaropoli, and V. Sergi, Investigation on Edge Joints of Inconel 625 Sheets Processed with Laser Welding, Opt. Laser Technol., 2017, 93, p 180–186

J.R. Poulin, A. Kreitcberg, P. Terriault, and V. Brailovski, Fatigue Strength Prediction of Laser Powder Bed Fusion Processed Inconel 625 Specimens with Intentionally-Seeded Porosity: Feasibility Study, Int. J. Fatigue, 2020, 132, p 105394

M. Tang and P.C. Pistorius, Fatigue Life Prediction for AlSi10Mg Components Produced by Selective Laser Melting, Int. J. Fatigue, 2019, 125, p 479–490

G. Qian, Z. Jian, X. Pan, and F. Berto, In-situ Investigation on Fatigue Behaviors of Ti-6Al-4 V Manufactured by Selective Laser Melting, Int. J. Fatigue, 2020, 133, p 105424

Y. Wu and R. Bao, Fatigue Crack Tip Strain Evolution and Crack Growth Prediction Under Single Overload in Laser Melting Deposited Ti-6.5Al-3.5Mo-1.5Zr-0.3Si Titanium Alloy, Int. J. Fatigue, 2018, 116, p 462–472

M. Seifi, A. Salem, J. Beuth, O. Harrysson, J.J. Lewandowski, and A. Erratum, Overview of Materials Qualification Needs for Metal Additive Manufacturing, JOM, 2016, 68(5), p 1492

M. Seifi, M. Gorelik, J. Waller, N. Hrabe, N. Shamsaei, S. Daniewicz, and J.J. Lewandowski, Progress Towards Metal Additive Manufacturing Standardization to Support Qualification and Certification, JOM, 2017, 69(3), p 439–455

Q.G. Wang, P.N. Crepeau, C.J. Davidson, and J.R. Griffiths, Oxide Films, Pores and the Fatigue Lives of Cast Aluminum Alloys, Metall. Mater. Trans. B, 2006, 37(6), p 887–895

J.P. Oliveira, Z. Zeng, C. Andrei, F.M. Braz Fernandes, R.M. Miranda, A.J. Ramirez, T. Omori, and N. Zhou, Dissimilar Laser Welding of Superelastic NiTi and CuAlMn Shape Memory Alloys, Mater. Design, 2017, 128, p 166–175

Y.L. Hu, X. Lin, Y.L. Li, S.Y. Zhang, X.H. Gao, F.G. Liu, X. Li, and W.D. Huang, Plastic Deformation Behavior and Dynamic Recrystallization of Inconel 625 Superalloy Fabricated by Directed Energy Deposition, Mater. Design., 2020, 186, p 108359

R.J. Goldstein, E.R.G. Eckert, W.E. Ibele, S.V. Patankar, T.W. Simon, T.H. Kuehn, P.J. Strykowski, K.K. Tamma, A. Bar-Cohen, J.V.R. Heberlein, J.H. Davidson, J. Bischof, F.A. Kulacki, U. Kortshagen, and S. Garrick, Heat Transfer—A Review of 2000 Literature, Int. J. Heat. Mass. Tran., 2002, 45(14), p 2853–2957

X.A. Hu, G.L. Zhao, Y. Jiang, X.F. Ma, F.C. Liu, J. Huang, and C.L. Dong, Experimental Investigation on the LCF Behavior Affected by Manufacturing Defects and Creep Damage of One Selective Laser Melting Nickel-Based Superalloy at 815 °C, Acta Metall. Sin-Engl., 2019 (in press) https://doi.org/10.1007/s40195-019-00986-0

A.J. Sterling, B. Torries, N. Shamsaei, S.M. Thompson, and D.W. Seely, Fatigue Behavior and Failure Mechanisms of Direct Laser Deposited Ti–6Al–4V, Mater. Sci. Eng., A, 2016, 655, p 100–112

Z.H. Jiao, L.M. Lei, H.C. Yu, F. Xu, R.D. Xu, and X.R. Wu, Experimental Evaluation on Elevated Temperature Fatigue and Tensile Properties of one Selective Laser Melted Nickel Based Superalloy, Int. J. Fatigue, 2019, 121, p 172–180

H.H. Shi, J.S. Hou, J.T. Guo, L.Z. Zhou, M. Maldini, G. Angella, R. Donini, and D. Ripamonti, Microstructure Evolution and Its Influence on Deformation Mechanisms During Tensile Creep of DD417G Alloy, Mater. Res. Innov., 2014, 18(S4), p 319–323

A. Epishin and T. Link, Mechanisms of High-Temperature Creep of Nickel-Based Superalloys Under Low Applied Stresses, Philos. Mag., 2004, 84(19), p 1979–2000

Y.T. Tang, P. Karamched, J. Liu, J.C. Haley, R.C. Reed, and A.J. Wilkinson, Grain Boundary Serration in Nickel Alloy Inconel 600: Quantification and Mechanisms, Acta Mater., 2019, 181, p 352–366

J.N. DuPont, J.C. Lippold, and S.D. Kiser, Welding Metallurgy and Weldability of Nickel-Base Alloys (DuPont/Welding Metallurgy)|| Appendix D: Etching Techniques for Ni-base Alloys and Welds, 2009, p 419-422, https://doi.org/10.1002/9780470500262.app4

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, Y., Hu, X. & Jiang, Y. Study on the Microstructure and Fatigue Behavior of a Laser-Welded Ni-Based Alloy Manufactured by Selective Laser Melting Method. J. of Materi Eng and Perform 29, 2957–2968 (2020). https://doi.org/10.1007/s11665-020-04844-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04844-4