Abstract

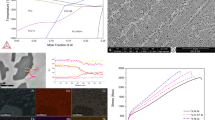

There has been great attention on high-entropy alloys (HEAs) over the past decade. Unlike conventional alloy systems, HEAs commonly include at least five principal elements with equiatomic or near-equiatomic ratio. HEAs with their superior mechanical, magnetic, and thermal properties are promising materials for critical engineering applications. Medium-entropy alloys (MEAs), which consist of less than five principal elements, have very similar structural features with HEAs such as robust thermodynamic stability and exceptional mechanical performance. The insights of MEAs have not been fully revealed yet. In the present study, novel MEAs (Cu20Ni20Al30Ti30, Cu25Ni25Al25Ti25, Cu34Ni22Al22Ti22, and Cu35Ni25Al20Ti20) have been designed using thermo-physical calculations and Thermo-Calc software. These MEAs were then produced using copper heart arc melting and suction cast into cylindrical rods with 3 mm diameters. X-ray diffraction (XRD), optical microscope (OM), transmission electron microscope (TEM), scanning electron microscope (SEM), and energy-dispersive spectroscopy (EDS) were used for structural characterization. The corresponding results reveal that the Cu20Ni20Al30Ti30, MEA, consists of a body-centered cubic (BCC-B2) phase with intermetallic compounds (ICs), whereas Cu25Ni25Al25Ti25 has single BCC-B2 phase. When the amounts Cu and Ni are increased, system drives itself toward a face-centered cubic (FCC) structure. A dual BCC and FCC composite Cu35Ni25Al20Ti20 has been detected as the most promising MEA among the others with 820 and 1338 MPa measured yield and compressive strength, respectively.

Similar content being viewed by others

References

J.W. Yeh, S.K. Chen, S.J. Lin, J.Y. Gan, T.S. Chin, T.T. Shun, C.H. Tsau, and S.Y. Chang, Nanostructured High-Entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6(5), p 299–303

J.W. Yeh, Recent Progress in High-Entropy Alloys, Annales de Chimie: Science des Materiaux, 2006, 31(6), p 633–648

Y. Zhang and Y.J. Zhou, Solid Solution Formation Criteria for High Entropy Alloys, Mater. Sci. Forum, 2007, 561–565, p 1337–1339

Y. Zhang, Y.J. Zhou, J.P. Lin, G.L. Chen, and P.K. Liaw, Solid-Solution Phase Formation Rules for Multi-Component Alloys, Adv. Eng. Mater., 2008, 10(6), p 534–538

X. Yang and Y. Zhang, Prediction of High-Entropy Stabilized Solid-Solution in Multi-component Alloys, Mater. Chem. Phys., 2012, 132(2–3), p 233–238

J.W. Yeh, Alloy Design Strategies and Future Trends in High-Entropy Alloys, JOM, 2013, 65(12), p 1759–1771

C.-J. Tong, Y.-L. Chen, S.-K. Chen, J.-W. Yeh, T.-T. Shun, C.-H. Tsau, S.-J. Lın, and S.-Y. Chang, Microstructure Characterization of Al, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2005, 36(4), p 881–893

J. Li, W. Jia, J. Wang, H. Kou, D. Zhang, and E. Beaugnon, Enhanced Mechanical Properties of a CoCrFeNi High Entropy Alloy by Supercooling Method, Mater. Des., 2016, 95, p 183–187

B.S. Murty, High-Entropy Alloys, Butterworth-Heinemann, Oxford, 2014

H. Yao, J.W. Qiao, M.C. Gao, J.A. Hawk, S.G. Ma, and H. Zhou, MoNbTaV Medium-Entropy Alloy, Entropy, 2016, 18(5), p 1–15

S. Gorsse, J.P. Couzinié, and D.B. Miracle, From High-Entropy Alloys to Complex Concentrated Alloys, Comptes Rendus Physique, 2018, 19(8), p 721–736

Y. Yu, J. Wang, J. Li, H. Kou, and W. Liu, Characterization of BCC Phases in AlCoCrFeNiTix High Entropy Alloys, Mater, Lett., 2015, 138, p 78–80

S. Guo, Q. Hu, C. Ng, and C.T. Liu, More than Entropy in High-Entropy Alloys: Forming Solid Solutions or Amorphous Phase, Intermetallics, 2013, 41, p 96–103

T.T. Shun, L.Y. Chang, and M.H. Shiu, Microstructure and Mechanical Properties of Multiprincipal Component CoCrFeNiMox Alloys, Mater. Charact., 2012, 70, p 63–67

M.S. Lucas, L. Mauger, J.A. Muoz, Y. Xiao, A.O. Sheets, S.L. Semiatin, J. Horwath, and Z. Turgut, Magnetic and Vibrational Properties of High-Entropy Alloys, J. Appl. Phys., 2011, 109(7), p 107–110

L. Zhang, Y. Zhou, X. Jin, X. Du, and B. Li, The Microstructure and High-Temperature Properties of Novel Nano Precipitation-Hardened Face Centered Cubic High-Entropy Superalloys, Scripta Mater., 2018, 146, p 226–230

S. Gangireddy, B. Gwalani, V. Soni, R. Banerjee, and R.S. Mishra, Contrasting Mechanical Behavior in Precipitation Hardenable Al X CoCrFeNi High Entropy Alloy Microstructures: Single Phase FCC Versus Dual Phase FCC-BCC, Mater. Sci. Eng. A, 2019, 739, p 158–166

Z. Li, K.G. Pradeep, Y. Deng, D. Raabe, and C.C. Tasan, Metastable High-Entropy Dual-Phase Alloys Overcome the Strength-Ductility Trade-Off, Nature, 2016, 534(7606), p 227–230

S. Guo, C. Ng, and C.T. Liu, Anomalous Solidification Microstructures in Co-Free Al XCrCuFeNi2 High-Entropy Alloys, J. Alloys Compd., 2013, 557, p 77–81

J.M. Park, J. Moon, J.W. Bae, D.H. Kim, Y.H. Jo, S. Lee, and H.S. Kim, Role of BCC Phase on Tensile Behavior of Dual-Phase Al 0.5 CoCrFeMnNi High-Entropy Alloy at Cryogenic Temperature, Mater. Sci. Eng. A, 2019, 746, p 443–447

K.R. Lim, K.S. Lee, J.S. Lee, J.Y. Kim, H.J. Chang, and Y.S. Na, Dual-Phase High-Entropy Alloys for High-Temperature Structural Applications, J. Alloys Compd., 2017, 728, p 1235–1238

R. Chen, G. Qin, H. Zheng, L. Wang, Y. Su, Y.L. Chiu, H. Ding, J. Guo, and H. Fu, Composition Design of High Entropy Alloys Using the Valence Electron Concentration to Balance Strength and Ductility, Acta Mater., 2018, 144, p 129–137

Y.F. Ye, C.T. Liu, and Y. Yang, A Geometric Model for Intrinsic Residual Strain and Phase Stability in High Entropy Alloys, Acta Mater., 2015, 94, p 152–161

A.K. Singh, N. Kumar, A. Dwivedi, and A. Subramaniam, A Geometrical Parameter for the Formation of Disordered Solid Solutions in Multi-component Alloys, Intermetallics, 2014, 53, p 112–119

Z. Wang, Y. Huang, Y. Yang, J. Wang, and C.T. Liu, Atomic-Size Effect and Solid Solubility of Multicomponent Alloys, Scripta Mater., 2015, 94, p 28–31

V.K. Soni, S. Sanyal, and S.K. Sinha, Phase Evolution and Mechanical Properties of Novel FeCoNiCuMox High Entropy Alloys, Vacuum, 2019, 2020(174), p 109173

Y. Lu, Y. Dong, L. Jiang, T. Wang, T. Li, and Y. Zhang, A Criterion for Topological Close-Packed Phase Formation in High Entropy Alloys, Entropy, 2015, 17(4), p 2355–2366

Y. Dong, Y. Lu, L. Jiang, T. Wang, and T. Li, Effects of Electro-Negativity on the Stability of Topologically Close-Packed Phase in High Entropy Alloys, Intermetallics, 2014, 52, p 105–109

Y. Zhou, D. Zhou, X. Jin, L. Zhang, X. Du, and B. Li, Design of Non-Equiatomic Medium-Entropy Alloys, Sci. Rep., 2018, 8(1), p 1236

A. Gali and E.P. George, Tensile Properties of High- and Medium-Entropy Alloys, Intermetallics, 2013, 39, p 74–78

G. Laplanche, A. Kostka, C. Reinhart, J. Hunfeld, G. Eggeler, and E.P. George, Reasons for the Superior Mechanical Properties of Medium-Entropy CrCoNi Compared to High-Entropy CrMnFeCoNi, Acta Materialia, 2017, 128, p 292–303

A. Takeuchi, K. Amiya, T. Wada, K. Yubuta, W. Zhang, and A. Makino, Entropies in Alloy Design for High-Entropy and Bulk Glassy Alloys, Entropy, 2013, 15(9), p 3810–3821

D.B. Miracle and O.N. Senkov, A Critical Review of High Entropy Alloys and Related Concepts, Acta Materialia, 2017, 122, p 448–511

S. Gorsse, M.H. Nguyen, O.N. Senkov, and D.B. Miracle, Database on the Mechanical Properties of High Entropy Alloys and Complex Concentrated Alloys, Data Brief, 2018, 21, p 2664–2678

S. Fang, X. Xiao, L. Xia, W. Li, and Y. Dong, Relationship between the Widths of Supercooled Liquid Regions and Bond Parameters of Mg-Based Bulk Metallic Glasses, J. Non-Cryst. Solids, 2003, 321(1–2), p 120–125

A. Kumar, A.K. Swarnakar, A. Basu, and M. Chopkar, Effects of Processing Route on Phase Evolution and Mechanical Properties of CoCrCuFeNiSix High Entropy Alloys, J. Alloys Compd., 2018, 748, p 889–897

S. Guo, C. Ng, J. Lu, and C.T. Liu, Effect of Valence Electron Concentration on Stability of Fcc or Bcc Phase in High Entropy Alloys, J. Appl. Phys., 2011, 109(10), p 103505

M.C. Gao, C. Zhang, P. Gao, F. Zhang, L.Z. Ouyang, M. Widom, and J.A. Hawk, Thermodynamics of Concentrated Solid Solution Alloys, Curr. Opin. Solid State Mater. Sci., 2017, 21(5), p 238–251

M.H. Tsai, K.Y. Tsai, C.W. Tsai, C. Lee, C.C. Juan, and J.W. Yeh, Criterion for Sigma Phase Formation in Cr- and V-Containing High-Entropy Alloys, Mater. Res. Lett., 2013, 1(4), p 207–212

L. Jiang, Y.P. Lu, H. Jiang, T.M. Wang, B.N. Wei, Z.Q. Cao, and T.J. Li, Formation Rules of Single Phase Solid Solution in High Entropy Alloys, Mater. Sci. Technol. (United Kingdom), 2016, 32(6), p 588–592

R. Feng, M.C. Gao, C. Lee, M. Mathes, T. Zuo, S. Chen, J.A. Hawk, Y. Zhang, and P.K. Liaw, Design of Light-Weight High-Entropy Alloys, Entropy, 2016, 18(9), p 16–29

X.D. Xu, S. Guo, T.G. Nieh, C.T. Liu, A. Hirata, and M.W. Chen, Effects of Mixing Enthalpy and Cooling Rate on Phase Formation of AlxCoCrCuFeNi High-Entropy Alloys, Materialia, 2019, 6, p 100292

B.S. Murty, J.W. Yeh, S. Ranganathan, B.S. Murty, J.W. Yeh, and S. Ranganathan, Phase Selection in High-Entropy Alloys, High Entropy Alloys, 2014, 3, p 37–56

G. Bizhanova, F. Li, Y. Ma, P. Gong, and X. Wang, Development and Crystallization Kinetics of Novel Near-Equiatomic High-Entropy Bulk Metallic Glasses, J. Alloys Compd., 2019, 779, p 474–486

S. Tripathy, G. Gupta, and S.G. Chowdhury, High Entropy Alloys: Criteria for Stable Structure, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2018, 49(1), p 7–17

A. Takeuchi and A. Inoue, Classification of Bulk Metallic Glasses by Atomic Size Difference, Heat of Mixing and Period of Constituent Elements and Its Application to Characterization of the Main Alloying Element, Mater. Trans., 2005, 46(12), p 2817–2829

H. Kotan and K.A. Darling, A Study of Microstructural Evolution of Fe-18Cr-8Ni, Fe-17Cr-12Ni, and Fe-20Cr-25Ni Stainless Steels after Mechanical Alloying and Annealing, Mater. Charact., 2018, 138, p 186–194

W. Li, P.K. Liaw, and Y. Gao, Fracture Resistance of High Entropy Alloys: A Review, Intermetallics, 2018, 99, p 69–83

M. Seifi, D. Li, Z. Yong, P.K. Liaw, and J.J. Lewandowski, Fracture Toughness and Fatigue Crack Growth Behavior of As-Cast High-Entropy Alloys, JOM, 2015, 67(10), p 2288–2295

Z. An, H. Jia, Y. Wu, P.D. Rack, A.D. Patchen, Y. Liu, Y. Ren, N. Li, and P.K. Liaw, Solid-Solution CrCoCuFeNi High-Entropy Alloy Thin Films Synthesized by Sputter Deposition, Mater. Res. Lett., 2015, 3(4), p 203–209

Z. Li, L. Fu, J. Peng, H. Zheng, X. Ji, Y. Sun, S. Ma, and A. Shan, Improving Mechanical Properties of an FCC High-Entropy Alloy by Γ′ and B2 Precipitates Strengthening, Mater. Charact., 2019, 2020(159), p 109989

Acknowledgment

This work is supported by the Scientific and Technological Research Council of Turkey (TUBITAK) under Grant No. 216M058. The authors would like to thank ONATUS Öngörü Teknolojileri Company for the support with the Thermo-Calc software.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Polat, G., Erdal, Z.A. & Kalay, Y.E. Design of Novel Non-equiatomic Cu-Ni-Al-Ti Composite Medium-Entropy Alloys. J. of Materi Eng and Perform 29, 2898–2908 (2020). https://doi.org/10.1007/s11665-020-04830-w

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04830-w