Abstract

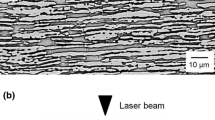

This paper is on the cavitation erosion (CE) behavior of a thermally annealed duplex stainless steel having a triplex microstructure consisting of ferrite, austenite and sigma phase. As sigma forms, it siphons off alloying elements from ferrite, making it softer. Ferrite is the weakest against CE among the three phases, and its interfaces with sigma phase are often the initiation sites of damage which tends to grow into the ferrite side. The weakness of ferrite stems from its high strain-rate sensitivity. Austenite is beneficial because it helps to prevent sigma phase from being dislodged, and its interfaces with sigma phase are also more resistant to CE damage. Mechanical properties such as hardness and strength do not correlate with CE resistance (as measured by cumulative weight loss and the incubation time of CE damage). Preliminary results show that cumulative weight loss is not monotonically proportional to the quantity of sigma.

Similar content being viewed by others

References

D. Ferreno, J.A. Alvarez, E. Ruiz, D. Mendez, L. Rodriguez, and D. Hernandez, Failure Analysis of a Pelton Turbine Manufactured in Soft Martensitic Stainless Steel Casting, Eng. Fail. Anal., 2011, 18(1), p 256–270

R. Singh, S.K. Tiwari, and S.K. Mishra, Cavitation Erosion In Hydraulic Turbine Components and Mitigation By Coatings: Current Status and Future Needs, J. Mater. Eng. Perform., 2012, 21(7), p 1539–1551

K. Selvam, P. Mandal, H.S. Grewal, and H.S. Arora, Ultrasonic Cavitation Erosion–Corrosion Behavior of Friction Stir Processed Stainless Steel, Ultrason. Sonochem., 2018, 44, p 331–339

W.T. Fu, Y.B. Yang, T.F. Jing, Y.Z. Zheng, and M. Yao, The Resistance to Cavitation Erosion of CrMnN Stainless Steels, J. Mater. Eng. Perform., 1998, 7, p 801–804

C.J. Heathcock, B.E. Protheroe, and A. Ball, Cavitation Erosion of Stainless Steels, Wear, 1982, 81(2), p 311–327

Columbia Metals Ltd. www.columbiametals.com/files/products/121.pdf. Accessed 15 Oct 2019

www.vanvoordenfoundry.com/cms_file.php?FromDB=3890&forceDownload (Stainless steel propellers instead of bronze? Newsletter No. 1. Van Voorden Foundry), and also at http://www.nsalloys.com/stainless-steel/avoid-propeller-cavitation-by-using-stainless-steel.html (The advantages to using stainless steel boat propellers). Accessed 17 Oct 2019

A. Karimi, Cavitation Erosion of a Duplex Stainless Steel, Mater. Sci. Eng., 1987, 86, p 191–203

A. Al-Hashem, P.G. Caceres, A. Abdullah, and H.M. Shalaby, Cavitation Corrosion of Duplex Stainless Steel in Seawater, Corrosion, 1997, 53(2), p 103–113

M. Hattestrand, P. Larsson, G. Chai, J.O. Nilsson, and J. Odqvist, Study of Decomposition of Ferrite in a Duplex Stainless Steel Cold Worked and Aged at 450–500 °C, Mater. Sci. Eng. A, 2009, 499(1–2), p 489–492

M. Pohl, O. Storz, and T. Glogowski, Effect of Intermetallic Precipitations on the Properties of Duplex Stainless Steel, Mater. Charact., 2008, 58(1), p 65–71

S.S.M. Tavares, A. Loureiro, J.M. Pardal, T.R. Montenegro, and V.C. da Costa, Influence of Heat Treatments at 475 and 400 °C on the Pitting Corrosion Resistance and Sensitization of UNS S32750 and UNS S32760 Superduplex Stainless Steels, Mater. Corros., 2012, 63(6), p 522–526

W. Ai, K.H. Lo, and C.T. Kwok, Cavitation Erosion of a Spinodally Decomposed Wrought Duplex Stainless Steel in a Benign Environment, Wear, 2019, 424–425, p 111–121

F. Marques, W.M. da Silva, J.M. Pardal, S.S.M. Tavares, and C. Scandiana, Influence of Heat Treatments on the Micro-abrasion Wear Resistance of a Superduplex Stainless Steel, Wear, 2011, 271(1–10), p 1288–1294

J.L. del Abra-Arzola, M.A. García-Rentería, V.L. Cruz-Hernández, J. García-Guerra, V.H. Martínez-Landeros, L.A. Falcón-Franco, and F.F. Curiel-Lopez, Study of the Effect of Sigma Phase Precipitation on the Sliding Wear and Corrosion Behaviour of Duplex Stainless Steel AISI, 2205, Wear, 2018, 400–401, p 43–51

J. Wan, H. Ruan, J. Wang, and S. Shi, The Kinetic Diagram of Sigma Phase and Its Precipitation Hardening Effect on 15Cr-2Ni Duplex Stainless Steel, Mater. Sci. Eng. A, 2019, 711, p 571–578

V.S. Moura, L.D. Lima, J.M. Pardal, A.Y. Kina, R.R.A. Corte, and S.S.M. Tavares, Influence of Microstructure on the Corrosion Resistance of the Duplex Stainless Steel UNS S31803, Mater. Charact., 2008, 59(8), p 1127–1132

S.S.M. Tavares, J.M. Pardal, J.L. Guerreiro, A.M. Gomes, and M.R. da Silva, Magnetic Detection of Sigma Phase in Duplex Stainless Steel UNS S31803, J. Magn. Magn. Mater., 2010, 322(17), p L29–L33

V.A. Hosseini, L. Karlsson, D. Engelberg, and S. Wessman, Time-Temperature-Precipitation and Property Diagrams for Super Duplex Stainless Steel Weld Metals, Weld. World, 2018, 62(3), p 517–533

C.R. de Farias Azevedo, H.B. Pereira, S. Wolynec, and A.F. Padilha, An Overview of the Recurrent Failures of Duplex Stainless Steels, Eng. Fail. Anal., 2019, 97, p 161–188

J. Olsson and M. Snis, Duplex—A New Generation of Stainless Steels for Desalination Plants, Desalination, 2007, 205(1–3), p 104–113

H.M. Ezubera, A. El-Houdb, and F. El-Shawesh, Effects of Sigma Phase Precipitation on Seawater Pitting of Duplex Stainless Steel, Desalination, 2007, 207(1–3), p 268–275

C.J. Park, V.S. Rao, and H.S. Kwon, Effects of Sigma Phase on the Initiation and Propagation of Pitting Corrosion of Duplex Stainless Steel, Corrosion, 2005, 61(1), p 76–83

D.Y. Kobayashi and S. Wolynec, Evaluation of the Low Corrosion Resistant Phase Formed During the Sigma Phase Precipitation in Duplex Stainless Steels, Mater. Res., 1999, 2(4), p 239–247

J. Basumatary and R.J.K. Wood, Different Methods of Measuring Synergy between Cavitation Erosion and Corrosion for Nickel Aluminium Bronze in 3.5% NaCl Solution, Tribol. Int., 2017, https://doi.org/10.1016/j.triboint.2017.08.006

G. Gao and Z. Zhang, Cavitation Erosion Behavior of 316L Stainless Steel, Tribol. Lett., 2019, https://doi.org/10.1016/j.ultsonch.2019.104668

J.M. Vitek and S.A. David, The Sigma Phase Transformation in Austenitic Stainless Steels, Weld. J., 1986, 65, p 106s–111s

C.C. Hsieh and W. Wu, Overview of Intermetallic Sigma (Sigma Phase) Phase Precipitation in Stainless Steels, Int. Sch. Res. Netw. ISRN Metall., 2012, https://doi.org/10.5402/2012/732471

T. Ohmura, K. Tsuzaki, K. Sawada, and K. Kimura, Inhomogeneous Nano-mechanical Properties in the Multi-phase Microstructure of Long-Term Aged Type 316 Stainless Steel, J. Mater. Res., 2006, 21(5), p 1229–1236

N. Llorca-Isern, H. Lopez-Luque, I. Lopez-Jimenez, and M.V. Biezma, Identification of Sigma and Chi Phases in Duplex Stainless Steels, Mater. Charact., 2016, 112, p 20–29

I. Tzanakis, L. Bolzoni, D.G. Eskin, and M. Hadfield, Evaluation of Cavitation Erosion Behavior of Commercial Steel Grades Used in the Design of Fluid Machinery, Metall. Mater. Trans. A, 2017, 48, p 2193–2206

W.J. Tomlinson and S.J. Matthews, Cavitation Erosion of Aluminium Alloys, J. Mater. Sci., 1994, 29(4), p 1101–1108

M.G.D.V. Cuppari, R.M. Souza, and A. Sinatora, Effect of Hard Second Phase on Cavitation Erosion of Fe-Cr-Ni-C Alloys, Wear, 2005, 258(1–4), p 596–603

B.G. Giren, M. Szkodo, and J. Steller, Cavitation Erosion of Some Laser-produced Iron-Base Corrosion-Resistant Alloys, Wear, 2005, 258(1–4), p 614–622

K. Kondoh, J. Umeda, and R. Watanabe, Cavitation Resistance of Powder Metallurgy Aluminum Matrix Composite with AlN Dispersoids, Mater. Sci. Eng. A, 2009, 499(1–2), p 440–444

R.H. Richman and W.P. McNaughton, Correlation of Cavitation Rrosion Behavior with Mechanical Properties of Metals, Wear, 1990, 140(1), p 63–82

S.J. Pawel and E.T. Manneschmidt, Preliminary Evaluation of Cavitation Resistance of Type 316LN Stainless Steel in Mercury Using a Vibratory Horn, J. Nucl. Mater., 2003, 318, p 122–131

K. Peng, C. Kang, G. Li, K. Matsuda, and H. Soyama, Effect of Heat Treatment on the Cavitation Erosion Resistance of Stainless Steel, Mater. Corros., 2018, 69(4), p 536–544

S. Zhang, C.L. Wu, C.H. Zhang, M. Guan, and J.Z. Tan, Laser Surface Alloying of FeCoCrAlNi High-entropy Alloy on 304 Stainless Steel to Enhance Corrosion and Cavitation Erosion Resistance, Opt. Laser Technol., 2016, 84, p 23–31

The Nickel Development Institute (NiDI). Design Guidelines for the Selection and Use of Stainless Steels—A Designers’ Handbook Series No. 9014.

Acknowledgments

Funded by the University of Macau through a Multi-Year Research Grant (MYRG2018-00030-FST).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ai, W., Lo, K.H., Li, X. et al. Cavitation Erosion Damage Mechanism of a Duplex Stainless Steel Having a Ferrite-Austenite-Sigma-Phase Triplex Microstructure. J. of Materi Eng and Perform 29, 2806–2815 (2020). https://doi.org/10.1007/s11665-020-04807-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04807-9