Abstract

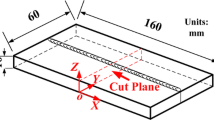

This paper presents the welding residual stress distribution in thick specimens after postweld treatments (postweld heat treatment—PWHT, and ultrasonic impact treatment—UIT). Three specimens with a thickness of 40 mm were multipass butt-welded by the gas metal arc welding (GMAW). The surface stresses were evaluated by the hole-drilling (HD) and the x-ray diffraction (XRD) methods, while the internal stresses were determined by the contour method (CM). It is found that UIT has a local effect on the welding residual stress. It can convert the tensile welding stresses into compressive stresses and introduce about a 3-6 mm compressive stress layer at the treated surface with little effect on the stresses outside the treated region and the stress distribution in the interior weld zone. Additionally, UIT shows the same effect on the surface longitudinal and transverse stresses, which results in a similar distribution and magnitude of compressive longitudinal and transverse stresses on the treated regions. PWHT has a global stress release of the welding residual stress, resulting in almost uniform stress distribution in the specimen with the range from − 200 to 100 MPa. PWHT also causes the release of the compressive transverse stress in the interior.

Similar content being viewed by others

References

M.N. James, Residual Stress Influences on Structural Reliability, Eng. Fail. Anal., 2011, 18(8), p 1909–1920

A.M. Paradowska, J.W.H. Price, R. Ibrahim, T.R. Finlayson, M.I. Ripley, and R. Blevins, The Effects of Restraint and Post-weld Heat Treatment on Residual Stress Distribution in a Bead-on-plate Weld, J. Neutron Res., 2007, 15(3–4), p 231–241

C.C. Huang and T.H. Chuang, Effects of Post-weld Heat Treatments on the Residual Stress and Mechanical Properties of Laser Beam Welded SAE 4130 Steel Plates, Mater. Manuf. Process., 1997, 12(5), p 779–797

R. Duan, Z. Luo, Y. Li, Y. Zhang, and Z.M. Liu, Novel Postweld Heat Treatment Method for Improving Mechanical Properties of Resistance Spot Weld, Sci. Technol. Weld. Join., 2015, 20(2), p 100–105

M. Hirohata, Effect of Post Weld Heat Treatment on Steel Plate Deck with Trough Rib by Portable Heat Source, Weld. World, 2017, 61(6), p 1225–1235

J. Yu, G. Gou, L. Zhang, W. Zhang, H. Chen, and Y.P. Yang, Ultrasonic Impact Treatment to Improve Stress Corrosion Cracking Resistance of Welded Joints of Aluminum Alloy, J. Mater. Eng. Perform., 2016, 25(7), p 3046–3056

X. Cheng, J.W. Fisher, H.J. Prask, T. Gnäupel-Herold, B.T. Yen, and S. Roy, Residual Stress Modification by Post-weld Treatment and Its Beneficial Effect on Fatigue Strength of Welded Structures, Int. J. Fatigue, 2003, 25(9–11), p 1259–1269

M. Turski, S. Clitheroe, A.D. Evans, C. Rodopoulos, D.J. Hughes, and P.J. Withers, Engineering the Residual Stress State and Microstructure of Stainless Steel with Mechanical Surface Treatments, Appl. Phys. A Mater., 2010, 99(3), p 549–556

M. Khurshid, M. Leitner, Z. Barsoum, and C. Schneider, Residual Stress State Induced by High Frequency Mechanical Impact Treatment in Different Steel Grades-Numerical and Experimental Study, Int. J. Mech. Sci., 2017, 123, p 34–42

A. Abdullah, M. Malaki, and A. Eskandari, Strength Enhancement of the Welded Structures by Ultrasonic Peening, Mater. Des., 2012, 38, p 7–18

H. Gao, R.K. Dutta, R.M. Huizenga, M. Amirthalingam, M.J.M. Hermans, T. Buslaps, and I.M. Richardson, Stress Relaxation Due to Ultrasonic Impact Treatment on Multi-pass Welds, Weld, Sci. Technol. Weld. Join., 2014, 19(6), p 505–513

X. An, C.A. Rodopoulos, E.S. Statnikov, V.N. Vitazev, and O.V. Korolkov, Study of the Surface Nanocrystallization Induced by the Esonix Ultrasonic Impact Treatment on the Near-Surface of 2024-T351 Aluminum Alloy, J. Mater. Eng. Perform., 2006, 15(3), p 355–364

E. Harati, L.E. Svensson, L. Karlsson, and M. Widmark, Effect of High Frequency Mechanical Impact Treatment on Fatigue Strength of Welded 1300 MPa Yield Strength Steel, Int. J. Fatigue, 2016, 92(Part1), p 96–106

B. Qiang, Y. Li, C. Yao, X. Wang, and Y. Gu, Through-Thickness Distribution of Residual Stresses in Q345qD Butt-Welded Steel Plates, J. Mater. Process. Technol., 2018, 251, p 54–64

V. Fontanari, F. Frendo, Th Bortolamedi, and P. Scardi, Comparison of the Hole-Drilling and X-ray Diffraction Methods for Measuring the Residual Stresses in Shot-peened Aluminium Alloys, J. Strain Anal. Eng. Des., 2005, 40(2), p 199–209

P.J. Withers and H.K.D.H. Bhadeshia, Residual Stress. Part 1—Measurement Techniques, Mater. Sci. Technol., 2001, 17(4), p 355–365

M.B. Prime, Cross-Sectional Mapping of Residual Stresses by Measuring the Surface Contour After a Cut, J. Eng. Mater. Technol., 2001, 123(2), p 162–168

N.S. Rossini, M. Dassisti, K.Y. Benyounis, and A.G. Olabi, Methods of Measuring Residual Stresses in Components, Mater. Des., 2012, 35, p 572–588

R. Gadallah, S. Tsutsumi, K. Hiraoka, and H. Murakawa, Prediction of Residual Stresses Induced by Low Transformation Temperature Weld Wires and Its Validation Using the Contour Method, Mar. Struct., 2015, 44, p 232–253

C. Liu and X. Yi, Residual Stress Measurement on AA6061-T6 Aluminum Alloy Friction Stir Butt Welds Using Contour Method, Mater. Des., 2013, 46, p 366–371

W. Rae, Z. Lomas, M. Jackson, and S. Rahimi, Measurements of Residual Stress and Microstructural Evolution in Electron Beam Welded Ti-6Al-4V Using Multiple Techniques, Mater. Charact., 2017, 132, p 10–19

C. Liu, D. Chen, M.R. Hill, M.N. Tran, and J. Zou, Effects of Ultrasonic Impact Treatment on Weld Microstructure, Hardness, and Residual Stress, Mater. Sci. Technol., 2017, 33(14), p 1601–1609

P. Pagliaro, M.B. Prime, H. Swenson, and B. Zuccarello, Measuring Multiple Residual-Stress Components Using the Contour Method and Multiple Cuts, Exp. Mech., 2010, 50(2), p 187–194

B.N. Mordyuk and G.I. Prokopenko, Ultrasonic Impact Peening for the Surface Properties’ Management, J. Sound Vib., 2007, 308, p 855–866

A.C. Sekkal, C. Langlade, and A.B. Vannes, A Micro/macro Impact Test at Controlled Energy for Erosion and Phase-transformation Simulation, Tribol. Lett., 2003, 15(3), p 265–274

ASTM E837-13a, ASTM International, Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain Gage Method, ASTM International, Philadelphia, 2013

D. Thibault, P. Bocher, and M. Thomas, Residual Stress and Microstructure in Welds of 13%Cr-4%Ni Martensitic Stainless Steel, J. Mater. Process. Technol., 2009, 209, p 2195–2202

C. Liu, Q. Ge, D. Chen, F. Gao, and J. Zou, Residual Stress Variation in a Thick Welded Joint After Ultrasonic Impact Treatment, Sci. Technol. Weld. Join., 2016, 21(4), p 624–631

C. Liu, Y. Yan, X. Cheng, C. Wang, and Y. Zhao, Residual Stress in a Restrained Specimen Processed by Post-weld Ultrasonic Impact Treatment, Sci. Technol. Weld. Join., 2019, 24(3), p 193–199

M.B. Prime, M.R. Hill, A.T. DeWald, R.J. Sebring, M.J. Cola, Residual Stress Mapping in Welds Using the Contour Method, Proceedings of the 6th International Conference, April 15-19, 2002, Pine Mountain, Georgia, S.A. David et al., Ed., ASM International, Philadelphia, 2003, p 891–896

L.K. Keppas, R.C. Wimpory, D.E. Katsareas, and C. Ohms, Combination of Simulation and Experiment in Designing Repair Weld Strategies: A Feasibility Study, Nucl. Eng. Des., 2010, 240(10), p 2897–2906

Y. Traoré, F. Hosseinzadeh, and P.J. Bouchard, Plasticity in the Contour Method of Residual Stress Measurement, Adv. Mater. Res., 2014, 996, p 337–342

S. Shin, FEM Analysis of Plasticity-Induced Error on Measurement of Welding Residual Stress by the Contour Method, J. Mech. Sci. Technol., 2005, 19(10), p 1885–1890

V. Richter-Trummer, E. Suzano, M. Beltrão, A. Roos, J.F. dos Santos, and P.M.S.T. de Castro, Influence of the FSW Clamping Force on the Final Distortion and Residual Stress Field, Mater. Sci. Eng. A, 2012, 538, p 81–88

M.B. Toparli and M.E. Fitzpatrick, Development and Application of the Contour Method to Determine the Residual Stresses in Thin Laser-Peened Aluminium Alloy Plates, Exp. Mech., 2016, 56(2), p 323–330

P.J. Withers, Residual Stress and Its Role in Failure, Rep. Prog. Phys., 2007, 70(12), p 2211–2264

P. Dong, S. Song, and J. Zhang, Analysis of Residual Stress Relief Mechanisms in Post-Weld Heat Treatment, Int. J. Press. Vess. Pip., 2014, 122, p 6–14

K.J. Kirkhope, R. Bell, L. Caron, R.I. Basu, and K.-T. Ma, Weld Detail Fatigue Life Improvement Techniques. Part 1: Review, Mar. Struct., 1999, 12, p 447–474

Acknowledgments

This work is supported by the National Natural Science Foundation of China (No. 51575251), the Natural Science Foundation of Jiangsu Province (BK20171308) and the National Key Research and Development Program of China (No. 2018YFC0310400).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Liu, C., Shen, J., Yan, J. et al. Experimental Investigations on Welding Stress Distribution in Thick Specimens After Postweld Heat Treatment and Ultrasonic Impact Treatment. J. of Materi Eng and Perform 29, 1820–1829 (2020). https://doi.org/10.1007/s11665-020-04731-y

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04731-y