Abstract

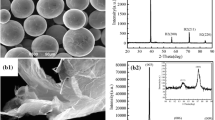

Two types of graphite nanoflakes (GNFs), GNFA for 30-100 μm in diameter and less than 100 nm in thickness, and GNFB for 0.5-10 μm in diameter and less than 20 nm in thickness, were used to fabricate GNF/6061Al matrix composites with GNF fractions ranging from 5 to 15 wt.% via spark plasma sintering (SPS) at 610 °C under a load of 35 MPa. The effects of GNF size and content on microstructures and properties of the composites were investigated. The results show that uniform mixing of GNFs in the 6061Al powder was achieved through mechanical and ultrasonic stirring. When the GNFs were well dispersed, the composites were dense. An interfacial zone of 15-18 nm in thickness was formed and composed of two layers, a poorly crystalline layer and an amorphous layer. No Al4C3 was detected in the interfacial zone. The relative densities, bending strengths, thermal conductivities (TCs), and coefficients of thermal expansion (CTEs) (room temperature to 100 °C) of the 10 wt.% GNFA/6061Al matrix composites were 98.5%, 120 MPa, 155 W m−1 K−1 in the X–Y direction and 61 W m−1 K−1 in the Z direction, and 14.2 ppm K−1 in the X–Y direction and 12.1 ppm K−1 in the Z direction, respectively. Those of the 10 wt.% GNFB/6061Al matrix composites were 97.8%, 70 MPa, 110 W m−1 K−1 in the X–Y direction and 90 W m−1 K−1 in the Z direction, and 15.4 ppm K−1 in the X–Y direction and 14.7 ppm K−1 in the Z direction, respectively. The GNFB/6061Al matrix composites showed lower differences of TC and CTE between the X–Y and Z directions. Therefore, the anisotropy of the microstructures and properties of the composites in three dimensions were significantly reduced.

Similar content being viewed by others

References

G. Yuan, X. Li, Z. Dong, A. Westwood, Z.W. Cui, Y. Cong, H.D. Du, and F.Y. Kang, Graphite Blocks with Preferred Orientation and High Thermal Conductivity, Carbon, 2012, 50, p 175–182

C. Zweben, Ultrahigh-Thermal-Conductivity Packaging Materials, in IEEE: Twenty First Annual IEEE Semiconductor Thermal Measurement and Management Symposium, March 15–17, 2005 (IEEE, San Jose, CA, USA, 2005).

S.S. Sidhu, S. Kumar, and A. Batish, Metal Matrix Composites for Thermal Management: A Review, Crit. Rev. Solid State Mater. Sci., 2016, 41, p 132–157

J.D. Mathias, P.M. Geffroy, and J.F. Silvain, Architectural Optimization for Microelectronic Packaging, Appl. Therm. Eng., 2009, 29, p 2391–2395

V. Oddone, B. Boerner, and R. Reich, Composites of Aluminum Alloy and Magnesium Alloy with Graphite Showing Low Thermal Expansion and High Specific Thermal Conductivity, Sci. Technol. Adv. Mater., 2017, 8, p 180–186

H. Kwon, M. Estili, K. Takagi, T. Miyazaki, and A. Kawasaki, Combination of Hot Extrusion and Spark Plasma Sintering for Producing Carbon Nanotube Reinforced Aluminum Matrix Composites, Carbon, 2008, 47, p 570–577

M. Rashad, F. Pan, A. Tang, and M. Asif, Effect of Graphene Nanoplatelets Addition on Mechanical Properties of Pure Aluminum Using a Semi-powder Method, Prog. Nat. Sci., 2014, 24, p 101–108

A.A. Balandin, S. Ghosh, W. Bao, I. Calizo, D. Teweldebrhan, F. Miao, and C.N. Lau, Superior Thermal Conductivity of Single-Layer Graphene, Nano Lett., 2008, 8, p 902–907

S.N. Alam and L. Kumar, Mechanical Properties of Aluminum-Based Metal Matrix Composites Reinforced with Graphite Nanoplatelets, Mater. Sci. Eng. A, 2016, 667, p 16–32

T.T. Liu, X.B. He, L. Zhang, Q. Liu, and X.H. Qu, Fabrication and Thermal Conductivity of Short Graphite Fiber/Al Composites by Vacuum Pressure Infiltration, J. Compos. Mater., 2014, 48, p 2207–2214

A. Saboori, M. Pavese, and C. Badini, Development of Al- and Cu-Based Nanocomposites Reinforced by Graphene Nanoplatelets: Fabrication and Characterization, Front. Mater. Sci., 2017, 11, p 171–181

X. Gao, H. Yue, E. Guo, H. Zhang, X.Y. Lin, L.H. Yao, and B. Wang, Mechanical Properties and Thermal Conductivity of Graphene Reinforced Copper Matrix Composites, Powder Technol., 2016, 301, p 601–607

A. Boden, B. Boerner, P. Kusch, I. Firkowska, and S. Reich, Nanoplatelet Size to Control the Alignment and Thermal Conductivity in Copper-Graphite Composites, Nano Lett., 2014, 14, p 3640–3644

G. Li and B. Xiong, Effects of Graphene Content on Microstructures and Tensile Property of Graphene-Nanosheets/Aluminum Composites, J. Alloys Compd., 2017, 697, p 31–36

M. Tokita, Trends in Advanced SPS Spark Plasma Sintering Systems and Technology, J. Soc. Powder. Technol. Jpn., 1993, 30, p 790–804

K. Mizuuchi, K. Inoue, Y. Agari, T. Nagaoka, M. Sugioka, M. Tanaka, T. Takeuchi, J. Tani, M. Kawahara, Y. Makino, and M. Ito, Processing of Al/SiC Composites in Continuous Solid–Liquid Co-existent State by SPS and Their Thermal Properties, Compos. B, 2012, 4, p 2012–2019

X.Z. Mao, Y.Q. Huang, and B.H. Wang, Fabrication, Microstructures and Properties of 50 vol.%/SiCp/6061Al Composites via a Pressureless Sintering Technique, Powder Metall., 2017, 61, p 1–9

A. Nieto, A. Bisht, D. Lahiri, C. Zhang, and A. Agarwal, Graphene Reinforced Metal and Ceramic Matrix Composites: A Review, Int. Mater. Rev., 2016, 62, p 241–302

A.C. Ferrari, J.C. Meyer, V. Scardaci, C. Casiraghi, M. Lazzeri, F. Mauri, S. Piscanec, D. Jiang, K.S. Novoselov, S. Roth, and A.K. Geim, Raman Spectrum of Graphene and Graphene Layers, Phys. Rev. Lett., 2016, 97, p 187401

C. Nabil, M. Diaa, D. Florence, C. Nathalie, Y.F. Lu, and J.F. Silvain, Effect of Flake Powder Metallurgy on Thermal Conductivity of Graphite Flakes Reinforced Aluminum Matrix Composites, J. Mater. Sci., 2018, 53, p 8180–8192

T. Varol and A. Canakci, Microstructure, Electrical Conductivity and Hardness of Multilayer Graphene/Copper Nanocomposites Synthesized by Flake Powder Metallurgy, Met. Mater. Int., 2015, 21, p 704–712

A. Saboori, M. Pavese, and C. Badini, Microstructure and Thermal Conductivity of Al-Graphene Composites Fabricated by Powder Metallurgy and Hot Rolling Techniques, Acta Metall. Sin., 2017, 30, p 675–687

D. Lin, L.C. Richard, and G.J. Cheng, Single-Layer Graphene Oxide Reinforced Metal Matrix Composites by Laser Sintering: Microstructure and Mechanical Property Enhancement, Acta Mater., 2014, 80, p 183–193

K. Bo, T.X. Fan, and J.M. Ru, Improved Wetting and Thermal Properties of Graphite-Cu Composite by Cr-Solution Immersion Method, Diam. Relat. Mater., 2016, 65, p 191–197

C. Zhou, G. Ji, Z. Chen, M.L. Wang, A. Addad, D. Schryvers, and H.W. Wang, Fabrication, Interface Characterization and Modeling of Oriented Graphite Flakes/Si/Al Composites for Thermal Management Applications, Mater. Des., 2014, 63, p 719–728

M.P. Liu, T.H. Jiang, X.F. Xie, Q. Liu, X.F. Li, and J.R. Hans, Microstructure Evolution and Dislocation Configurations in Nanostructured Al-Mg Alloys Processed by High Pressure Torsion, Trans. Nonferr. Met. Soc. China, 2014, 24, p 3848–3857

H. Kwon, M. Estili, K. Takagi, T. Miyazaki, and A. Kawasaki, Combination of Hot Extrusion and Spark Plasma Sintering for Producing Carbon Nanotube Reinforced Aluminum Matrix Composites, Carbon, 2009, 47, p 570–577

W. Li, Y. Liu, and G. Wu, Preparation of Graphite Flakes/Al with Preferred Orientation and High Thermal Conductivity by Squeeze Casting, Carbon, 2015, 95, p 545–551

T. Etter, P. Schulz, M. Weber, J. Metz, M. Wimmler, J.F. Löffler, and P.J. Uggowitzer, Aluminium Carbide Formation in Interpenetrating Graphite/Aluminium Composites, Mater. Sci. Eng. A, 2007, 448, p 1–6

T. Etter, J. Kuebler, T. Frey, P. Schulz, J.F. Löffler, and P.J. Uggowitzer, Strength and Fracture Toughness of Interpenetrating Graphite/Aluminium Composites Produced by the Indirect Squeeze Casting Process, Mater. Sci. Eng. A, 2004, 386, p 61–67

J. Leng, G. Wu, Q. Zhou, Z.Y. Dou, and X.L. Huang, Mechanical Properties of SiC/Gr/Al Composites Fabricated by Squeeze Casting Technology, Scr. Mater., 2008, 59, p 619–622

J.K. Chen and I.S. Huang, Thermal Properties of Aluminum-Graphite Composites by Powder Metallurgy, Compos. B, 2013, 44, p 698–703

F. Akhlaghi and A. Zare-Bidaki, Influence of Graphite Content on the Dry Sliding and Oil Impregnated Sliding Wear Behavior of Al2024/Graphite Composites Produced by In Situ Powder Metallurgy Method, Wear, 2009, 266, p 37–45

Y. Xu, Research on Preparation and Properties of Graphite/Copper Composites with High Thermal Conductivity, Master Thesis, Huazhong University of Science and Technology, China, vol 1 (2013), p. 33. (In Chinese).

J.Z. Xu, B.Z. Gao, and F.Y. Kang, A Reconstruction of Maxwell Model for Effective Thermal Conductivity of Composite Materials, Appl. Therm. Eng., 2016, 102, p 972–979

M. Xiao, X.W. Zhang, W.T. Xiao, J.J. Du, H.H. Song, and Z.K. Ma, The Influence of Chemical Constitution on the Structure and Properties of Polyimide Fibre and Their Graphite Fibre, Polymer, 2019, 165, p 142–151

P.M. Adams, H.A. Katzman, G.S. Rellick, and G.W. Stupian, Characterization of High Thermal Conductivity Carbon Fibers and a Self-reinforced Graphite Panel, Carbon, 1998, 36, p 233–245

L. Wei, R. Zhang, and C.P. Wong, Modeling of Thermal Conductivity of Graphite Nanosheet Composites, J. Electron. Mater., 2010, 39, p 268–272

K. Hiroki, M. Takamichi, K. Akira, Y.F. Lu, and J.F. Silvain, Interfacial Microstructure of Graphite Flake Reinforced Aluminum Matrix Composites Fabricated via Hot Pressing, Compos. A, 2015, 73, p 125–131

J.B. Nelson and D.P. Riley, The Thermal Expansion of Graphite from 15 to 800 °C: Part I. Experimental, Proc. Phys. Soc., 1945, 57, p 477

I. Firkowska, A. Boden, B. Boerner, and S. Reich, The Origin of High Thermal Conductivity and Ultralow Thermal Expansion in Copper-Graphite Composites, Nano Lett., 2015, 15, p 4745–4751

P.S. Turner, Thermal-Expansion Stresses in Reinforced Plastics, J. Res. Natl. Bur. Stand., 1946, 37, p 239–250

E.H. Kerner, The Elastic and Thermo-Elastic Properties of Composite Media, Proc. Phys. Soc. B, 1956, 69, p 808–813

X.M. Zhu, J.K. Yu, and X.Y. Wang, Microstructure and Properties of Al/Si/SiC Composites for Electronic Packaging, Trans. Nonferr. Met. Soc., 2012, 22, p 1686–1692

O.L. Blakslee, D.G. Proctor, E.J. Seldin, G.B. Spence, and T. Weng, Elastic Constants of Compression-Annealed Pyrolytic Graphite, J. Appl. Phys., 1970, 41, p 3373–3382

J. Sun, G.H. Chen, B.H. Wang, G.D. Chen, and W.M. Tang, Fabrication, Microstructures, and Properties of 50 vol.% SiCp/6061Al Composites via Hot Pressing, J. Mater. Eng. Perform., 2019, 28, p 2697–2706

Acknowledgments

This work was financially supported by International Science & Technology Cooperation Program of China (Grant Numbers 2014DFA50860).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Chen, G., Chang, H., Sun, J. et al. Microstructures and Properties of Graphite Nanoflake/6061Al Matrix Composites Fabricated via Spark Plasma Sintering. J. of Materi Eng and Perform 29, 1235–1244 (2020). https://doi.org/10.1007/s11665-020-04676-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04676-2