Abstract

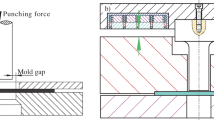

Electromagnetic (EM) perforation is a high-strain-rate shearing process of making holes in the workpiece by using an electromagnetic force. This process overcomes the disadvantages of conventional or quasistatic processes. In this work, the comparative study of the quality of holes perforated by the EM dieless perforation process and quasistatic dieless perforation process has been carried out and the differences are reported. This study allows one to understand the physical phenomena that happen during the perforation by the pointed and concave punch as well as the type of failure like the formation of petaling, plugging and softening or hardening of the material. The sheared edges are characterized using microscope, scanning electron microscopy (SEM) and microhardness analysis studies. Among interesting observations, it has been noticed that the smooth sheared depth, rollover depth, burr height and fracture depth are more in quasistatic dieless perforation. No significant change in hardness is observed in the case of quasistatic perforation, while in EM perforation, more than 50% increase in hardness is observed. The SEM observation has revealed that in both the perforation cases, ductile dimple growth is the prominent failure mode. The results obtained during this study show the capability of electromagnetic perforation to obtain perforated holes with better surface finish and material properties over the quasistatic perforation process.

Similar content being viewed by others

References

A.K. Rajak and S.D. Kore, Application of Electromagnetic Forming in Terminal Crimping Using Different Types of Field Shapers, J. Mech. Sci. Tech., 2018, 32(9), p 4291–4297

R. Neugebauer, K.D. Bouzakis, B. Denkena, F. Klocke, A. Sterzing, A.E. Tekkaya, and R. Wertheim, Velocity Effects in Metal Forming and Machining Processes, CIRP Ann. Manuf. Tech., 2011, 60(2), p 627–650

V. Psyk, D. Risch, B.L. Kinsey, A.E. Tekkaya, and M. Kleiner, Electromagnetic Forming a Review, J. Mater. Process. Technol., 2011, 211(5), p 787–829

H. Zhang, M. Murata, and H. Suzuki, Effects of Various Working Conditions on Tube Bulging by Electromagnetic Forming, J. Mater. Process. Technol., 1995, 48(1–4), p 113–121

P. Ghatule and S.D. Kore, Coupled 3D Finite Element Modeling of Electromagnetic Free Expansion of Al Tube, Adv. Mater. Manuf. Charact., 2013, 95, p 97

F.M. Song, X. Zhang, Z.R. Wang, and L.Z. Yu, A Study of Tube Electromagnetic Forming, J. Mech. Work. Technol., 2004, 151(1–3), p 372–375

H. Suzuki, M. Murata, and H. Negishi, The Effect of a Field Shaper in Electromagnetic Tube Bulging, J. Mech. Work. Technol., 1987, 15(2), p 229–240

S.M. Golowin, Path Actuators for Magnetic Pulse Assisted Forming and Punch-less Electro-Magnetic Shearing, Doctoral Dissertation-The Ohio State University (2008)

M. Gotoh and M. Yamashita, A study of High-Rate Shearing of Commercially Pure Aluminium Sheet, J. Mater. Process. Technol., 2001, 110(3), p 253–264

Z. Tekiner, M. Nalbant, and H. Gürün, An Experimental Study for the Effect of Different Clearances on Burr, Smooth-Sheared and Blanking Force on Aluminium Sheet Metal, Mater. Des., 2006, 27(10), p 1134–1138

S. Jana and N.S. Ong, Effect of Punch Clearance in the High-Speed Blanking of Thick Metals Using an Accelerator Designed for a Mechanical Press, J. Mech. Work. Technol., 1989, 19(1), p 55–72

T. Børvik, O.S. Hopperstad, T. Berstad, and M. Langseth, Perforation of 12 mm Thick Steel Plates by 20 mm Diameter Projectiles with Flat, Hemispherical and Conical Noses: Part II: Numerical Simulations, Int. J. Impact Eng., 2002, 27(1), p 37–64

A. Rusinek, J.A. Rodríguez-Martínez, R. Zaera, J.R. Klepaczko, A. Arias, and C. Sauvelet, Experimental and Numerical Study on the Perforation Process of Mild Steel Sheets Subjected to Perpendicular Impact by Hemispherical Projectiles, Int. J. Impact Eng., 2009, 36(4), p 565–587

M.E. Backman and W. Goldsmith, The Mechanics of Penetration of Projectiles into Targets, Int. J. Eng. Sci., 1978, 16(1), p 1–99

T. Børvik, M. Langseth, O.S. Hopperstad, and K.A. Malo, Perforation of 12 mm Thick Steel Plates by 20 mm Diameter Projectiles with Flat, Hemispherical and Conical Noses: Part I: Experimental Study, Int. J. Impact Eng., 2002, 27(1), p 19–35

S. Pawar and S.D. Kore, Electromagnetic Forming and Perforation of Al Tube, J. Mech. Sci. Technol., 2019, 33(12), p 5999–6007

W.M. Garrison, Jr, and N.R. Moody, Ductile Fracture, J. Phys. Chem. Solids, 1987, 48(11), p 1035–1074

R.W. Hertzberg, Deformation and Fracture Mechanics of Engineering Materials, J. Mater. Educ., 1997, 19, p 227–232

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pawar, S., Kore, S.D. & Nandy, A. Comparison of Sheared Edge Zones Developed in Electromagnetic and Quasistatic Dieless Perforation. J. of Materi Eng and Perform 29, 1146–1155 (2020). https://doi.org/10.1007/s11665-020-04636-w

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04636-w