Abstract

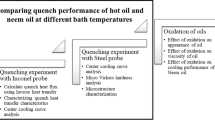

The present work presents a comprehensive comparative study on the cooling performance of hot oil and molten 54%KNO3-7%NaNO3-39%NaNO2 eutectic mixture quench media. The study was conducted using a cylindrical Inconel probe of 12.5 mm diameter and 60 mm length. Cooling curves at different locations in the probe were acquired and were subsequently used to calculate spatially dependent transient heat flux at the metal/quenchant interface. The heat extraction mechanism in hot oil and NaNO2 eutectic mixture was found to be different. Heat transfer occurred in two stages, namely boiling stage and convective cooling stage during quenching in molten NaNO2 eutectic mixture. In the case of hot oil, apart from these two stages, third stage of cooling, namely vapor blanket stage, was observed. A detailed study was conducted to compare the magnitude and uniformity of heat extraction during each stage of quenching. Molten salt offered a higher cooling rate and more spatial uniform cooling as compared to that obtained in hot oil quench medium. The non-uniformity in surface temperature during boiling stage in Inconel probe was ten times lower in molten salt medium as compared to that observed in the hot oil medium. However, the non-uniformity in surface temperature during convective cooling stage in both the media were comparable. Based on the distribution of characteristic cooling time (t85) calculated in quenched Inconel probe, higher and uniform hardness distribution is predicted in steel parts quenched in molten NaNO2 eutectic mixture media as compared to that in hot oil.

Similar content being viewed by others

References

G. Ramesh and K.N. Prabhu, Wetting and Cooling Performance of Mineral Oils for Quench Heat Treatment of Steels. ISIJ Int., 2014, 54(6), p 1426–1435. https://doi.org/10.2355/isijinternational.54.1426

B. Lisicic, H.M. Tensi, and L.C. Canale (eds.), Quenching Theory and Technology (CRC Press, Boca Raton, 2010)

M. Narazaki, G.E. Totten, and G.M. Webster, Hardening by Reheating and Quenching, Handbook of residual stress and deformation of steel, G.E. Totten, M. Howes, and T. Inoue, Eds., 1st ed. (ASM International, 2002), p 248–295.

C.E. Bates, G.E. Totten, and R.L. Brennan, Quenching, ASM Handbook Volume 4 Heat Treating, ASM Handbook Committee, Ed., (ASM International, Cleveland, 1991).

R. Sudheer and K. N. Prabhu, A Computer Aided Cooling Curve Analysis Method to Study Phase Change Materials for Thermal Energy Storage Applications, Mater. Des., 2016, 95, p 198–203. https://doi.org/10.1016/j.matdes.2016.01.053

G.P. Dubal, Salt Bath Quenching. Adv. Mater. Process., 1999, 156(6), p 23–28

C.A. Canbay , O. Karaduman, N. Ünlü , S.A. Baiz, and I. Ozkulb, Heat Treatment and Quenching Media Effects on the Thermodynamical, Thermoelastical and Structural Characteristics of a New Cu-Based Quaternary Shape Memory Alloy, Composites Part B, 2019, p 106940 (2019). https://doi.org/10.1016/j.compositesb.2019.106940

K.M. Pranesh Rao and K. Narayan Prabhu, Effect of Bath Temperature on Cooling Performance of Molten Eutectic NaNO3-KNO3 Quench Medium for Martempering of Steels, Metall. Mater. Trans. A, 2017, 48(10), p 4895–4904. https://doi.org/10.1007/s11661-017-4267-7.

G. Ramesh and K. Narayan Prabhu, Spatial Dependence of Heat Flux Transients and Wetting Behavior During Immersion Quenching of Inconel 600 Probe in Brine and Polymer Media, Metall. Mater. Trans. B, 2014, 45(4), p 1355–1369. https://doi.org/10.1007/s11663-014-0038-7.

A.G. Fernandez, H. Galleguillos, E. Fuentealba, and F.J. Perez, Thermal Characterization of HITEC Molten Salt for Energy Storage in Solar Linear Concentrated Technology. J Therm Anal Calorim., 2015, 122(1), p 3–9. https://doi.org/10.1007/s10973-015-4715-9

B. Smoljan, Prediction of Mechanical Properties and Microstructure Distribution of Quenched and Tempered Steel Shaft. J. Mater. Process. Technol., 2006, 175(1–3), p 393–397

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Rao, K.M.P., Prabhu, K.N. A Comparative Study on Cooling Performance of Hot Oil and Molten Salt Quench Media for Industrial Heat Treatment. J. of Materi Eng and Perform 29, 3494–3501 (2020). https://doi.org/10.1007/s11665-020-04635-x

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04635-x