Abstract

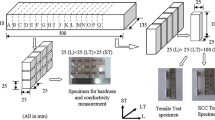

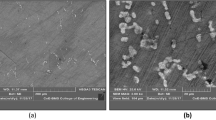

Multistage retrogression and reaging (RRA) heat treatment has been carried out on aluminum alloy AA7010. Each of the heat treatment steps for this alloy has been optimized on the basis of preliminary hardness and electrical conductivity measurements. These values were found to be a function of precipitate morphology and distribution. Samples were solution-treated (ST) with three different temperatures and quenching media, further aged at fixed temperature (120 °C) with time ranging from 24 to 120 h. Retrogression and reaging is done at 180-240 °C (for time duration of 2-60 min) and 120 °C (for 24-90 h), respectively. ST at 480 °C followed by warm water quenching (70 °C), aging cycle for T6 and T73 condition: 120 °C/42 h and 170 °C/128 h were found to be optimum. The optimum RRA conditions were achieved at retrogression parameters of 200 °C for 60 min and 240 °C for 60 min along with aging parameters of 120 °C/30 h and 120 °C/36 h, respectively. TEM images showed the presence of uniformly distributed precipitates in the matrix in RRA conditions. Statistical distribution of precipitates showed higher frequency of precipitates for RRA with optimized conditions RA1 (120 °C for 42 h + 200 °C for 60 min + 120 °C for 30 h) and RA2 (120 °C for 42 h + 240 °C for 60 min + 120 °C for 36 h).

Similar content being viewed by others

References

P.A. Rometsch, Y. Zhang, and S. Knight, Heat Treatment of 7XXX Series Aluminum Alloy—Some Recent Developments, Trans. Nonferr. Met. Soc. China, 2014, 24, p 2003–2017

E. Lavernia, G. Rai, and N.J. Grant, Rapid Solidification Processing of 7XXX Aluminum Alloys: A Review, Mater. Sci. Eng., A, 1986, 79, p 211–221

R. Ranganatha, V. Anil Kumar, S.N. Vaishaki, R.R. Bhat, and B.K. Muralidhara, Multistage Heat Treatment of Aluminum Alloy AA7049, Trans. Nonferr. Met. Soc. China, 2013, 23, p 1570–1575

X.J. Raizenne, M.D. Chen, and W.R. Poon, Thirty Years of Retrogression and Re Aging, in ICAS Congress, 2002, pp. 1–11

Q. Ying-dong, M. Rui, and Rong-de L. Jun-huaY, Study on Microstructure, Mechanical Properties and Corrosion Behaviour of Spray Formed 7075 Alloy, Mater. Today Commun., 2015, 4, p 109–115

F. Viana, A.M.P. Pinto, H.M.C. Santos, and A.B. Lopes, Retrogression and Re-ageing of 7075 Aluminum alloy; Microstructural Characterization, Mater. Proc. Technol., 1999, 92-93, p 54–59

A.F. Oliveira, M.C. Barros, K.R. Cardoso, and D.N. Travessa, The Effect of RRA on the Strength and SCC Resistance on AA7050 and AA7150 Aluminum Alloy, Mater. Sci. Eng., A, 2004, 379, p 321–326

G.F. Li, X.M. Zhang, P.H. Li, and J.H. You, Effects of Retrogression Heating Rate on Microstructures and Mechanical Properties of Aluminum Alloy 7050, Trans. Nonferr. Met. Soc. China, 2010, 20, p 935–941

S. Gang and C. Alfred, Early Stage Precipitation in Al-Zn-Mg-Cu Alloy (7050), Acta Mater., 2004, 52, p 4503–4516

N.M. Han, X.M. Zhang, S.D. Liu, and R. Zhang, Effect of Solution Treatment on the Strength and Fracture Toughness of Aluminum Alloys 7050, J. Alloys Compd., 2011, 509, p 4138–4145

J. Chen, L. Zhen, S. Yang, and S.L. Dai, Effects of Precipitates on Fatigue Crack Growth Rate of AA7055 Aluminum Alloy, Trans. Nonferr. Met. Soc. China, 2010, 20, p 2209–2214

K. Wen, Y. Fan, G. Wang, and L. Jin, Aging Behaviour and Precipitate Characterization of a High Zn-Containing Al-Zn-Mg-Cu Alloy with Various Tempers, Mater. Des., 2016, 101, p 16–23

P. Mrudula, K.C. Kshirod, and B.R. Raghavendra, Effect of Retrogression and Reaging Treatment on Properties of 7010 Aluminum Alloy Forgings, in National Conference on Challenges in Research & Technology in the Coming Decades, 2014

M. Bobby Kannan, R. Raman, A. Mukhopadhyay, and V.S. Raja, Influence of Multistep Aging on the Stress Corrosion Cracking Behavior of Aluminum Alloy 7010, Corros. Sci., 2003, 59, p 881–889

L.K. Berg, J. Gjonnes, V. Hansen, X.Z. Li, M.K. Wedel, G. Waterloo, D. Schryvers, and L.R. Warrenberg, GP Zones in Al-Zn-Mg Alloys and their Role in Artificial Aging, Acta Mater., 2001, 49, p 3443–3451

M.S. Nandana, K. Udaya Bhat, and C.M. Manjunatha, Effect of Retrogression Heat Treatment Time on Microstructure and Mechanical Properties of AA7010, J. Mater. Eng. Perform., 2017, https://doi.org/10.1007/s11665-018-3268-z

M.A. Krishnan and V.S. Raja, Development of High Strength AA 7010 Aluminum Alloy Resistant to Environmentally Assisted Cracking, Corros. Sci., 2016, 5, p 55. https://doi.org/10.1016/j.corsci.2016.03.025

G. Ozer and A. Karaaslan, Properties of AA7075 Aluminum Alloy in Aging and Retrogression and Reaging Process, Trans. Nonferr. Met. Soc. China, 2017, 27, p 2357–2362

A.K. Mukhopadhyay, K.S. Prasad, V. Kumar, G.M. Reddy, S.V. Kamat, and V.K. Varma, Key Microstructural Features Responsible for Improved Stress Corrosion Cracking Resistance and Weldability in 7xxx Series Al Alloys Containing Micro/Trace Alloying Additions, Mater. Sci. For., 2006, 519–521, p 315–320

P.L. Srinivasamurthy, B.N. Sarada, B.S. Karthik, and S.H. Shamanth, Effect of Retrogression and Reaging Heat Treatment on Microstructure and Corrosion Properties of Al-7075, Int. J. Innov. Res. Sci. Eng. Technol., 2013, 11, p 6434–6441

M. Shakouri, M. Esmailina, and S. Shabestari, Development of a Heat Treatment for Increasing the Mechanical Properties and Stress Corrosion Resistance of 7000 Al Alloys, Mater. Technol., 2017, https://doi.org/10.17222/mit.2016.297

Acknowledgments

Authors are thankful to HWMD/MMG for heat treatment and characterization support. They thank GM, MMA, DD, MME, VSSC for providing guidance during this work and Director, VSSC, for kind permission to publish the work.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Krishnanunni, S., Gupta, R.K., Ajithkumar, G. et al. Optimization of Heat Treatment Cycles and Characterization of Aluminum Alloy AA7010. J. of Materi Eng and Perform 28, 776–787 (2019). https://doi.org/10.1007/s11665-019-3861-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-3861-9