Abstract

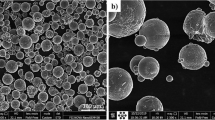

In the present study, the wear behavior of ultra-fine grained (UFG) Al-Mg alloys produced by a severe plastic deformation (SPD) method was assessed and compared against the annealed coarse-grained alloy. To this end, weight loss, wear resistance, friction coefficient, and morphology of the worn surfaces was investigated. Constrained groove pressing-cross route (CGP-CR) process, an SPD technique, was implemented at ambient temperature up to two passes to impose an equivalent plastic strain of about 4.64. Formation of a UFG structure with an average sub-grain size of ~ 350 nm with an enhanced tensile strength of up to ~ 225 MPa and indentation hardness of up to ~ 95 HV were achieved upon two passes of CGP-CR process. The pin-on-disk dry wear sliding testing was conducted up to a distance of 1000 m under normal loads of 5, 7, and 9 N at a constant sliding speed of 0.5 m/s. The trends measured for the evaluation of wear properties/mechanisms are discussed based on the microstructural features and mechanical property of UFGed alloys. The results showed that by employing the CGP-CR process and through the formation of UFG structure, the wear resistance was considerably increased. This was even beyond two times (~ 100%) larger depending on the normal loading with the lowest coefficient of friction around 0.6. Observation and study of the morphology of the worn surfaces under field emission-scanning electron microscopy (FE-SEM) revealed a change in the wear mechanism from sticking followed by formation of plastic deformation bands and delamination in the coarse-grained annealed alloy into a combined abrasive-adhesive behavior in the UFG material.

Similar content being viewed by others

References

R.Z. Valiev, R.K. Islamgaliev, and I.V. Alexandrov, Bulk Nanostructured Materials from Severe Plastic Deformation, Prog. Mater Sci., 2000, 45(2), p 103–189. https://doi.org/10.1016/S0079-6425(99)00007-9

R.Z. Valiev and T.G. Langdon, Principles of Equal-Channel Angular Pressing as a Processing Tool for Grain Refinement, Prog. Mater Sci., 2006, 51(7), p 881–981. https://doi.org/10.1016/j.pmatsci.2006.02.003

J.C. Benedyk, 3-Aluminum Alloys for Lightweight Automotive Structures A2-Mallick, P.K, Materials, Design and Manufacturing for Lightweight Vehicles, Woodhead Publishing, Cambridge, 2010, p 79–113

F. Khodabakhshi, A. Simchi, A.H. Kokabi, A.P. Gerlich, and M. Nosko, Effects of Stored Strain Energy on Restoration Mechanisms and Texture Components in an Aluminum-Magnesium Alloy Prepared by Friction Stir Processing, Mater. Sci. Eng. A, 2015, 642, p 204–214. https://doi.org/10.1016/j.msea.2015.07.001

F. Khodabakhshi and M. Kazeminezhad, The Effect of Constrained Groove Pressing on Grain Size, Dislocation Density and Electrical Resistivity of Low Carbon Steel, Mater. Des., 2011, 32(6), p 3280–3286. https://doi.org/10.1016/j.matdes.2011.02.032

F. Khodabakhshi, M. Kazeminezhad, and A.H. Kokabi, Constrained Groove Pressing of Low Carbon Steel: Nano-Structure and Mechanical Properties, Mater. Sci. Eng. A, 2010, 527(16-17), p 4043–4049. https://doi.org/10.1016/j.msea.2010.03.005

A.K. Gupta, T.S. Maddukuri, and S.K. Singh, Constrained Groove Pressing for Sheet Metal Processing, Prog. Mater Sci., 2016, 84, p 403–462. https://doi.org/10.1016/j.pmatsci.2016.09.008

S. Morattab, K. Ranjbar, and M. Reihanian, On the Mechanical Properties and Microstructure of Commercially Pure Al Fabricated by Semi-Constrained Groove Pressing, Mater. Sci. Eng. A, 2011, 528(22–23), p 6912–6918. https://doi.org/10.1016/j.msea.2011.05.074

E. Rafizadeh, A. Mani, and M. Kazeminezhad, The Effects of Intermediate and Post-Annealing Phenomena on the Mechanical Properties and Microstructure of Constrained Groove Pressed Copper Sheet, Mater. Sci. Eng. A, 2009, 515(1–2), p 162–168. https://doi.org/10.1016/j.msea.2009.03.081

S.S. Satheesh Kumar and T. Raghu, Tensile Behaviour and Strain Hardening Characteristics of Constrained Groove Pressed Nickel Sheets, Mater. Des., 2011, 32(8–9), p 4650–4657. https://doi.org/10.1016/j.matdes.2011.03.081

O. Unal, A. Cahit Karaoglanli, R. Varol, and A. Kobayashi, Microstructure Evolution and Mechanical Behavior of Severe Shot Peened Commercially Pure Titanium, Vacuum, 2014, 110, p 202–206. https://doi.org/10.1016/j.vacuum.2014.08.004

F. Khakbaz and M. Kazeminezhad, Strain Rate Sensitivity and Fracture Behavior of Severely Deformed Al-Mn Alloy Sheets, Mater. Sci. Eng. A, 2012, 532, p 26–30. https://doi.org/10.1016/j.msea.2011.10.057

E. Salvati, H. Zhang, K.S. Fong, R.J.H. Paynter, X. Song, and A.M. Korsunsky, Fatigue and Fracture Behaviour of AZ31b Mg Alloy Plastically Deformed by Constrained Groove Pressing in the Presence of Overloads, Procedia Struct. Integr., 2016, 2, p 3772–3781. https://doi.org/10.1016/j.prostr.2016.06.469

M. Moradpour, F. Khodabakhshi, and H. Eskandari, Dynamic Strain Aging Behavior of an Ultra-Fine Grained Al-Mg Alloy (AA5052) Processed via Classical Constrained Groove Pressing, J. Mater. Res. Technol., 2018, https://doi.org/10.1016/j.jmrt.2018.04.016

F. Khodabakhshi and M. Kazeminezhad, The Annealing Phenomena and Thermal Stability of Severely Deformed Steel Sheet, Mater. Sci. Eng. A, 2011, 528(15), p 5212–5218. https://doi.org/10.1016/j.msea.2011.03.024

F. Khodabakhshi and M. Kazeminezhad, Differential Scanning Calorimetry Study of Constrained Groove Pressed Low Carbon Steel: Recovery, Recrystallisation and Ferrite to Austenite Phase Transformation, Mater. Sci. Technol., 2014, 30(7), p 765–773. https://doi.org/10.1179/1743284713Y.0000000388

F. Khodabakhshi, M. Kazeminezhad, and A.H. Kokabi, Mechanical Properties and Microstructure of Resistance Spot Welded Severely Deformed Low Carbon Steel, Mater. Sci. Eng. A, 2011, 529, p 237–245. https://doi.org/10.1016/j.msea.2011.09.023

F. Khodabakhshi, M. Kazeminezhad, and A.H. Kokabi, Resistance Spot Welding of Ultra-Fine Grained Steel Sheets Produced By Constrained Groove Pressing: Optimization and Characterization, Mater. Charact., 2012, 69, p 71–83. https://doi.org/10.1016/j.matchar.2012.04.011

F. Khodabakhshi, M. Abbaszadeh, H. Eskandari, and S.R. Mohebpour, Application of CGP-Cross Route Process for Microstructure Refinement and Mechanical Properties Improvement in Steel Sheets, J. Manuf. Process., 2013, 15(4), p 533–541. https://doi.org/10.1016/j.jmapro.2013.08.001

F. Khodabakhshi, M. Abbaszadeh, S.R. Mohebpour, and H. Eskandari, 3D Finite Element Analysis and Experimental Validation of Constrained Groove Pressing–Cross Route as an SPD Process for Sheet Form Metals, Int. J. Adv. Manuf. Technol., 2014, 73(9), p 1291–1305. https://doi.org/10.1007/s00170-014-5919-z

M. Moradpour, F. Khodabakhshi, and H. Eskandari, Microstructure–Mechanical Property Relationship in an Al–Mg Alloy Processed by Constrained Groove Pressing-Cross Route, Mater. Sci. Technol., 2018, 34(8), p 1003–1017. https://doi.org/10.1080/02670836.2017.1416906

N. Gao, C.T. Wang, R.J.K. Wood, and T.G. Langdon, Tribological Properties of Ultrafine-Grained Materials Processed by Severe Plastic Deformation, J. Mater. Sci., 2012, 47(12), p 4779–4797. https://doi.org/10.1007/s10853-011-6231-z

M.I.A.E. Aal and H.S. Kim, Wear Properties of High Pressure Torsion Processed Ultrafine Grained Al–7%Si Alloy, Mater. Des., 2014, 53, p 373–382. https://doi.org/10.1016/j.matdes.2013.07.045

G. Purcek, H. Yanar, D.V. Shangina, M. Demirtas, N.R. Bochvar, and S.V. Dobatkin, Influence of High Pressure Torsion-Induced Grain Refinement and Subsequent Aging on Tribological Properties of Cu-Cr-Zr alloy, J. Alloys Compd., 2018, 742, p 325–333. https://doi.org/10.1016/j.jallcom.2018.01.303

İ. Çelik, A. Alsaran, and G. Purcek, Effect of Different Surface Oxidation Treatments on Structural, Mechanical and Tribological Properties of Ultrafine-Grained Titanium, Surf. Coat. Technol., 2014, 258, p 842–848. https://doi.org/10.1016/j.surfcoat.2014.07.073

G. Purcek, H. Yanar, O. Saray, I. Karaman, and H.J. Maier, Effect of Precipitation on Mechanical and Wear Properties of Ultrafine-Grained Cu-Cr-Zr Alloy, Wear, 2014, 311(1), p 149–158. https://doi.org/10.1016/j.wear.2014.01.007

G. Purcek, O. Saray, O. Kul, I. Karaman, G.G. Yapici, M. Haouaoui, and H.J. Maier, Mechanical and Wear Properties of Ultrafine-Grained Pure Ti Produced By Multi-Pass Equal-Channel Angular Extrusion, Mater. Sci. Eng. A, 2009, 517(1), p 97–104. https://doi.org/10.1016/j.msea.2009.03.054

G. Purcek, I. Karaman, G.G. Yapici, M. Al-Maharbi, T. Kuçukomeroglu, and O. Saray, Enhancement in Mechanical Behavior and Wear Resistance of Severe Plastically Deformed Two-Phase Zn–Al alloys, Int. J. Mater. Res., 2007, 98(4), p 332–338. https://doi.org/10.3139/146.101470

C.T. Wang, N. Gao, M.G. Gee, R.J.K. Wood, and T.G. Langdon, Processing of an Ultrafine-Grained Titanium By High-Pressure Torsion: An Evaluation of the Wear Properties with and Without a TiN Coating, J. Mech. Behav. Biomed. Mater., 2013, 17, p 166–175. https://doi.org/10.1016/j.jmbbm.2012.08.018

A.P. Zhilyaev, I. Shakhova, A. Belyakov, R. Kaibyshev, and T.G. Langdon, Wear Resistance and Electroconductivity in Copper Processed by Severe Plastic Deformation, Wear, 2013, 305(1–2), p 89–99. https://doi.org/10.1016/j.wear.2013.06.001

C. Gode, H. Yilmazer, I. Ozdemir, and Y. Todaka, Microstructural Refinement and Wear Property of Al–Si–Cu Composite Subjected to Extrusion and High-Pressure Torsion, Mater. Sci. Eng. A, 2014, 618, p 377–384. https://doi.org/10.1016/j.msea.2014.09.011

E. Avcu, The Influences of ECAP on the Dry Sliding Wear Behaviour of AA7075 Aluminium Alloy, Tribol. Int., 2017, 110, p 173–184. https://doi.org/10.1016/j.triboint.2017.02.023

M. Chegini, A. Fallahi, and M.H. Shaeri, Effect of Equal Channel Angular Pressing (ECAP) on Wear Behavior of Al-7075 Alloy, Procedia Mater. Sci., 2015, 11, p 95–100. https://doi.org/10.1016/j.mspro.2015.11.116

E. Darmiani, I. Danaee, M.A. Golozar, M.R. Toroghinejad, A. Ashrafi, and A. Ahmadi, Reciprocating Wear Resistance of Al–SiC Nano-Composite Fabricated by Accumulative Roll Bonding Process, Mater. Des., 2013, 50, p 497–502. https://doi.org/10.1016/j.matdes.2013.03.047

R. Jamaati, M. Naseri, and M.R. Toroghinejad, Wear Behavior of Nanostructured Al/Al2O3 Composite Fabricated via Accumulative Roll Bonding (ARB) Process, Mater. Des., 2014, 59, p 540–549. https://doi.org/10.1016/j.matdes.2014.03.027

M. Ebrahimi, S. Attarilar, F. Djavanroodi, C. Gode, and H.S. Kim, Wear Properties of Brass Samples Subjected to Constrained Groove Pressing Process, Mater. Des., 2014, 63, p 531–537. https://doi.org/10.1016/j.matdes.2014.06.043

F. Khodabakhshi, A. Simchi, A.H. Kokabi, M. Sadeghahmadi, and A.P. Gerlich, Reactive Friction Stir Processing of AA 5052–TiO2 Nanocomposite: Process–Microstructure–Mechanical Characteristics, Mater. Sci. Technol., 2015, 31(4), p 426–435. https://doi.org/10.1179/1743284714Y.0000000573

ASTM standard E8M, Tension Testing of Metallic Materials. Annual Book of ASTM Standards, ASTM, West Conshohocken, 1998

ASTM standard G99–04, Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus, ASTM International, West Conshohocken, PA, 2004

F. Khodabakhshi, A. Simchi, and A. Kokabi, Surface Modifications of an Aluminum-Magnesium Alloy Through Reactive Stir Friction Processing with Titanium Oxide Nanoparticles for Enhanced Sliding Wear Resistance, Surf. Coat. Technol., 2017, 309, p 114–123

F. Khodabakhshi, M. Kazeminezhad, and A.H. Kokabi, On the Failure Behavior of Highly Cold Worked Low Carbon Steel Resistance Spot Welds, Metall. Mater. Trans. A, 2014, 45(3), p 1376–1389. https://doi.org/10.1007/s11661-013-2074-3

F. Khodabakhshi, M. Kazeminezhad, and A.H. Kokabi, Metallurgical Characteristics and Failure Mode Transition for Dissimilar Resistance Spot Welds Between Ultra-Fine Grained and Coarse-Grained Low Carbon Steel Sheets, Mater. Sci. Eng. A, 2015, 637, p 12–22. https://doi.org/10.1016/j.msea.2015.04.019

M.I. Abd El Aal, N. El Mahallawy, F.A. Shehata, M. Abd El Hameed, E.Y. Yoon, and H.S. Kim, Wear Properties of ECAP-Processed Ultrafine Grained Al-Cu Alloys, Mater. Sci. Eng. A, 2010, 527(16–17), p 3726–3732. https://doi.org/10.1016/j.msea.2010.03.057

H.S. Arora, H. Singh, and B.K. Dhindaw, Wear Behaviour of a Mg Alloy Subjected to Friction Stir Processing, Wear, 2013, 303(1–2), p 65–77. https://doi.org/10.1016/j.wear.2013.02.023

J. Li, J. Wongsa-Ngam, J. Xu, D. Shan, B. Guo, and T.G. Langdon, Wear Resistance of an Ultrafine-Grained Cu-Zr Alloy Processed by Equal-Channel Angular Pressing, Wear, 2015, 326–327, p 10–19. https://doi.org/10.1016/j.wear.2014.12.022

N. Hansen, Hall–Petch Relation And Boundary Strengthening, Scr. Mater., 2004, 51(8), p 801–806. https://doi.org/10.1016/j.scriptamat.2004.06.002

M. Elmadagli, T. Perry, and A.T. Alpas, A Parametric Study of the Relationship Between Microstructure and Wear Resistance of Al-Si Alloys, Wear, 2007, 262(1), p 79–92. https://doi.org/10.1016/j.wear.2006.03.043

A. Shafiei-Zarghani, S.F. Kashani-Bozorg, and A.Z. Hanzaki, Wear Assessment of Al/Al2O3 Nano-Composite Surface Layer Produced Using Friction Stir Processing, Wear, 2011, 270(5–6), p 403–412. https://doi.org/10.1016/j.wear.2010.12.002

F. Ren, S.N. Arshad, P. Bellon, R.S. Averback, M. Pouryazdan, and H. Hahn, Sliding Wear-Induced Chemical Nanolayering in Cu-Ag, and Its Implications for High Wear Resistance, Acta Mater., 2014, 72, p 148–158. https://doi.org/10.1016/j.actamat.2014.03.060

G. Purcek, O. Saray, F. Rubitschek, T. Niendorf, H.J. Maier, and I. Karaman, Effect Of Internal Oxidation on Wear Behavior of Ultrafine-Grained Nb-Zr, Acta Mater., 2011, 59(20), p 7683–7694. https://doi.org/10.1016/j.actamat.2011.08.028

Author information

Authors and Affiliations

Corresponding author

Electronic Supplementary Material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Mozafari, J., Khodabakhshi, F., Eskandari, H. et al. Wear Resistance and Tribological Features of Ultra-Fine-Grained Al-Mg Alloys Processed by Constrained Groove Pressing-Cross Route. J. of Materi Eng and Perform 28, 1235–1252 (2019). https://doi.org/10.1007/s11665-019-3859-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-3859-3