Abstract

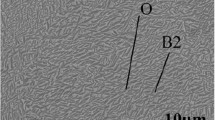

A Ti-22Al-25Nb alloy was fabricated from prealloyed powders by hot isostatic pressing for 2 h at a temperature of 1050 °C and pressure of 100 MPa. The hot deformation behavior of the Ti-22Al-25Nb alloy was characterized by isothermal compression testing at deformation temperatures between 900 and 1060 °C and strain rates between 0.001 and 1 s−1. Based on the true stress–strain curves, a constitutive equation was constructed to describe the flow stress as a function of the strain rate and deformation temperature. Three-dimensional (3D) processing maps were developed based on dynamic material model theory using the stress flow data to identify the instability and optimization regions of the hot processing parameters. The results show that the flow stress decreases with increasing deformation temperature and decreasing strain rate, and the softening mechanisms are different under different deformation conditions. The apparent activation energies in the (α2 + β/B2 + O) and (α2 + B2) phase regions are calculated to be 865.177 and 590.661 kJ/mol, respectively, which suggests that the hot isostatic pressed (HIPed) Ti-22Al-25Nb alloy requires a high hot deformation activation energy. Combined with microstructural observations, the optimal processing domains are determined to be a temperature range of 1030-1060 °C and strain rate range of 0.01-0.1 s−1 in the α2 + B2 phase region. Moreover, the results indicate that adiabatic shear bands and severe inhomogeneous deformation cause flow instability at lower temperatures (900-1005 °C) and higher strain rates (> 0.1 s−1).

Similar content being viewed by others

References

K. Muraleedharan, T.K. Nandy, D. Banerjee, and S. Lele, Phase Stability and Ordering Behaviour of the O Phase in Ti-Al-Nb Alloys, Intermetallics, 1995, 3(3), p 187–199

C.J. Boehlert, B.S. Majumdar, V. Seetharaman, and D.B. Miracle, Part I. The Microstructural Evolution in Ti-Al-Nb O + Bcc Orthorhombic Alloys, Metall. Mater. Trans. A, 1999, 30(9), p 2305–2323

D. Banerjee, A.K. Gogia, T.K. Nandy, and V.A. Joshi, A New Ordered Orthorhombic Phase in a Ti3Al-Nb Alloy, Acta Metall., 1988, 36(4), p 871–882

F.C. Dary and T.M. Pollock, Effects of High Temperature Air and Vacuum Exposures on the Room Temperature Tensile Behavior of the (O + B2) Titanium Aluminide Ti-22Al-23Nb, Mater. Sci. Eng. A, 1996, 208(2), p 188–202

M. Hagiwara, S. Emura, A. Araoka, B.O. Kong, and F. Tang, Enhanced Mechanical Properties of Orthorhombic Ti2AlNb-Based Intermetallic Alloy, Met. Mater. Int., 2003, 9(3), p 265–272

C.J. Cowen and C.J. Boehlert, Microstructure, Creep, and Tensile Behavior of a Ti-21Al-29Nb (at.%) Orthorhombic + B2 Alloy, Intermetallics, 2006, 14(4), p 412–422

J.H. Peng, Y. Mao, S.Q. Li, and X.F. Sun, Microstructure Controlling by Heat Treatment and Complex Processing for Ti2AlNb Based Alloys, Mater. Sci. Eng. A, 2001, 299(1–2), p 75–80

M. Hagiwara, S. Emura, A. Araoka, S.J. Yang, and S.W. Nam, The Effect of Lamellar Morphology on Tensile and High-Cycle Fatigue Behavior of Orthorhombic Ti-22Al-27Nb Alloy, Metall. Trans. A, 2004, 35(7), p 2161–2170

L. Germann, D. Banerjee, J.Y. Guedou, and J.L. Strudel, Effect of Composition on the Mechanical Properties of Newly Developed Ti2AlNb-Based Titanium Aluminide, Intermetallics, 2005, 13(9), p 920–924

C. Xue, W.D. Zeng, W. Wang, X.B. Liang, and J.W. Zhang, Coarsening Behavior of Lamellar Orthorhombic Phase and Its Effect on Tensile Properties for the Ti-22Al-25Nb Alloy, Mater. Sci. Eng. A, 2014, 611, p 320–325

S.V. Kamat, A.K. Gogia, and D. Banerjee, Effect of Alloying Elements and Heat Treatment on the Fracture Toughness of Ti-Al-Nb Alloys, Acta Mater., 1998, 46(1), p 239–251

P. Lin, Z.B. He, S.J. Yuan, and J. Shen, Tensile Deformation Behavior of Ti-22Al-25Nb Alloy at Elevated Temperatures, Mater. Sci. Eng. A, 2012, 556, p 617–624

C.J. Boehlert, The Effects of Forging and Rolling on Microstructure in O + BCC Ti-Al-Nb Alloys, Mater. Sci. Eng. A, 2000, 279(1–2), p 118–129

P.R. Smith, A.H. Rosenberger, M.J. Shepard, and R. Wheeler, IV, Review A P/M Approach for the Fabrication of an Orthorhombic Titanium Aluminide for MMC Applications, J. Mater. Sci., 2000, 35(13), p 3169–3179

J.B. Jia, K.F. Zhang, and S.S. Jiang, Microstructure and Mechanical Properties of Ti-22Al-25Nb Alloy Fabricated by Vacuum Hot Pressing Sintering, Mater. Sci. Eng. A, 2014, 616, p 93–98

Y.X. Wang, K.F. Zhang, and B.Y. Li, Microstructure and High Temperature Tensile Properties of Ti-22Al-25Nb Alloy Prepared by Reactive Sintering with Element Powders, Mater. Sci. Eng. A, 2014, 608, p 229–233

K.H. Sim, G.F. Wang, J.M. Ju, J.L. Yang, and X. Li, Microstructure and Mechanical Properties of a Ti-22Al-25Nb Alloy Fabricated from Elemental Powders by Mechanical Alloying and Spark Plasma Sintering, J. Alloys Compd., 2017, 704, p 425–433

J. Wu, L. Xu, Z.G. Lu, B. Lu, Y.Y. Cui, and R. Yang, Microstructure Design and Heat Response of Powder Metallurgy Ti2AlNb Alloys, J. Mater. Sci. Technol., 2015, 31(12), p 1251–1257

C. Chao, S. Bo, P. Xue, Q. Wei, J.M. Wu, L. Wei, and Y. Shi, Effect of Hot Isostatic Pressing Procedure on Performance of Ti6Al4V: Surface Qualities, Microstructure and Mechanical Properties, J. Alloys Compd., 2016, 686, p 55–63

X. Ma, W.D. Zeng, B. Xu, Y. Sun, C. Xue, and Y.F. Han, Characterization of the hot Deformation Behavior of a Ti-22Al-25Nb Alloy Using Processing Maps Based on the Murty Criterion, Intermetallics, 2012, 20(1), p 1–7

Y.V.R.K. Prasad and T. Seshacharyulu, Modelling of Hot Deformation for Microstructural Control, Int. Mater. Rev., 1998, 43(6), p 243–258

J.L. Zhang, H.Z. Guo, and H.Q. Liang, Hot Deformation Behavior and Process Parameter Optimization of Ti-22Al-25Nb Using Processing Map, Rare Met., 2016, 35(1), p 118–126

J.B. Jia, K.F. Zhang, L.M. Liu, and F.Y. Wu, Hot Deformation Behavior and Processing Map of a Powder Metallurgy Ti-22Al-25Nb Alloy, J. Alloys Compd., 2014, 600, p 215–221

S. Wang, W. Xu, Y. Zong, X. Zhong, and D. Shan, Effect of Initial Microstructures on Hot Deformation Behavior and Workability of Ti2AlNb-Based Alloy, Metals, 2018, 8(6), p 382

A. Mohamadizadeh, A. Zarei-Hanzaki, H. Abedi, S. Mehtonen, and D. Porter, Hot Deformation Characterization of Duplex Low-Density Steel Through 3D Processing Map Development, Mater. Charact., 2015, 107, p 293–301

J. Liu, Z. Cui, and C. Li, Analysis of Metal Workability by Integration of FEM and 3-D Processing Maps, J. Mater. Proc. Technol., 2008, 205(1–3), p 497–505

G.Z. Quan, L. Zhang, X. Wang, and Y.L. Li, Correspondence Between Microstructural Evolution Mechanisms and Hot Processing Parameters for Ti-13Nb-13Zr Biomedical Alloy in Comprehensive Processing Maps, J. Alloys Compd., 2017, 698, p 178–193

A.K. Gogia, T.K. Nandy, D. Banerjee, T. Carisey, J.L. Strudel, and J.M. Franchet, Microstructure and Mechanical Properties of Orthorhombic Alloys in the Ti-Al-Nb System, Intermetallics, 1998, 6(7–8), p 741–748

J. Zhang, J. Wu, Y. Luo, X. Mao, D. Guo, S. Zhao, and F. Yang, Hot Deformation Mechanisms of Ti-22Al-25Nb Orthorhombic Alloy, J. Mater. Eng. Perform., 2019, 28(2), p 973–980

W. Wang, W. Zeng, C. Xue, X. Liang, and J. Zhang, Microstructural Evolution, Creep, Tensile Behavior of a Ti–22Al–25Nb (at.%) Orthorhombic Alloy, Mater. Sci. Eng. A, 2014, 603, p 176–184

G. Chen, X.S. Chang, J.X. Zhang, J. Yu, C. Sun, Q. Chen, and Z.D. Zhao, Microstructures and Mechanical Properties of In-Situ Al3Ti/2024 Aluminum Matrix Composites Fabricated by Ultrasonic Treatment and Subsequent Squeeze Casting, Met. Mater. Int. 2019. https://doi.org/10.1007/s12540-019-00396-y

Y.C. Lin, D.G. He, M.S. Chen, X.M. Chen, C.Y. Zhao, X. Ma, and Z.L. Long, EBSD Analysis of Evolution of Dynamic Recrystallization Grains and δ Phase in a Nickel-Based Superalloy During Hot Compressive Deformation, Mater. Des., 2016, 97, p 13–24

J. Jia, K. Zhang, and Z. Lu, Dynamic Recrystallization Kinetics of a Powder Metallurgy Ti-22Al-25Nb Alloy During Hot Compression, Mater. Sci. Eng. A, 2014, 607, p 630–639

Y.C. Lin and X.M. Chen, A Critical Review of Experimental Results and Constitutive Descriptions for Metals and Alloys in Hot Working, Mater. Des., 2011, 32(4), p 1733–1759

J.K. Fan, H.C. Kou, M.J. Lai, B. Tang, H. Chang, and J.S. Li, Characterization of Hot Deformation Behavior of a New Near Beta Titanium Alloy: Ti-7333, Mater. Des., 2013, 49, p 945–952

A.B. Li, L.J. Huang, Q.Y. Meng, L. Geng, and X.P. Cui, Hot Working of Ti-6Al-3Mo-2Zr-0.3Si Alloy with Lamellar α + β Starting Structure Using Processing Map, Mater. Des., 2009, 30(5), p 1625–1631

I. Philippart and H.J. Rack, High Temperature Dynamic Yielding in Metastable Ti-6.8Mo-4.5F-1.5Al, Mater. Sci. Eng. A, 1998, 243(1–2), p 196–200

W.D. Zeng, Y. Shu, X.M. Zhang, Y.G. Zhou, Y.Q. Zhao, H. Wu, Y. Dai, J. Yang, and L. Zhou, Hot Workability and Microstructure Evolution of Highly β Stabilised Ti-25V-15Cr-0.3Si alloy, Mater. Sci. Technol., 2008, 24(10), p 1222–1229

C.M. Sellars and W.J. McTegart, On the Mechanism of Hot Deformation, Acta Mater., 1966, 14(9), p 1136–1138

C. Zener and J.H. Hollomon, Effect of Strain Rate Upon Plastic Flow of Steel, J. Appl. Phys., 1944, 15(1), p 22–32

G.Z. Quan, L. Zhao, T. Chen, Y. Wang, Y.P. Mao, W.Q. Lv, and J. Zhou, Identification for the Optimal Working Parameters of As-Extruded 42CrMo High-Strength Steel from a Large Range of Strain, Strain Rate and Temperature, Mater. Sci. Eng. A, 2012, 538, p 364–373

Y.V.R.K. Prasad and T. Seshacharyulu, Processing Maps for Hot Working of Titanium Alloys, Mater. Sci. Eng. A, 1998, 243(1–2), p 82–88

C.M. Sellars and W.J. Tegart, Relationship Between Strength and Structure in Deformation at Elevated Temperatures, Mem. Sci. Rev. Met., 1966, 63(9), p 731–745

T. Seshacharyulu, S.C. Medeiros, W.G. Frazier, and Y.V.R.K. Prasad, Microstructural Mechanisms During Hot Working of Commercial Grade Ti-6Al-4V with Lamellar Starting Structure, Mater. Sci. Eng. A, 2002, 325(1–2), p 112–125

Y.C. Lin, L.T. Li, Y.C. Xia, and Y.Q. Jiang, Hot Deformation and Processing Map of a Typical Al-Zn-Mg-Cu Alloy, J. Alloys Compd., 2013, 550, p 438–445

C. Zhang and K. Zhang, Superplasticity of a γ-TiAl Alloy and Its Microstructure and Cavity Evolution in Deformation, J. Alloys Compd., 2010, 492, p 236–240

Acknowledgments

The authors express their appreciation for the financial support of National Natural Science Foundation of China under Grant Nos. 51875121 and 51905122, Plan of Key Research and Development in Shandong Province under Grant Nos. 2017GGX202006 and 2019GGX102046, Natural Science Foundation in Shandong Province under Grant No. ZR2019MEE039.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhang, H., Yang, M., Xu, Y. et al. Constitutive Behavior and Hot Workability of a Hot Isostatic Pressed Ti-22Al-25Nb Alloy during Hot Compression. J. of Materi Eng and Perform 28, 6816–6826 (2019). https://doi.org/10.1007/s11665-019-04453-w

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-019-04453-w